1997 S10 Blazer help Eats distributor caps!!!!

#1

I am looking for some input here, my blazer has 110,000 miles for it, and is the 4.3 vortec and goees through a cap about every 6 months, sometimes shorter. What i develop is a low speed miss, generally noticiable when starting off from a stop.

I have changed the distributor cap and rotor about 6 times, every time it fixes the problem for about 3-6 months. Gererally this only happes during wet weather and when it is cold. If left unfixed it gets worse and worse.

Upon inspection of the old distributor cap you can see marks when the spark is jumping all over. It is never wet, but usually has some debris that can be whiped off the inside.

I have no idea why this keeps happening, does anyone have any input??? i am stumped!!

I feel as if moisture is getting into the cap and causing this, what do i do?? and why does this only happen to me? The truck is even stored in the garage

I have changed the distributor cap and rotor about 6 times, every time it fixes the problem for about 3-6 months. Gererally this only happes during wet weather and when it is cold. If left unfixed it gets worse and worse.

Upon inspection of the old distributor cap you can see marks when the spark is jumping all over. It is never wet, but usually has some debris that can be whiped off the inside.

I have no idea why this keeps happening, does anyone have any input??? i am stumped!!

I feel as if moisture is getting into the cap and causing this, what do i do?? and why does this only happen to me? The truck is even stored in the garage

#2

If the rotor is physically contacting the terminals of the cap, the distributor bushings are worn out and the distributor needs replacement. As for caps and rotors, these engines are very fussy when it comes to secondary ignition parts: (Spark plugs, plug wires, distributor cap & rotor, and ignition coil) AC Delco parts should be used, especially cap & rotor. When the cap is replaced, a dab of silicone dielectric grease should be applied to each terminal, inside and out. When spark jumps from the rotor to the cap, the grease crystalizes... normal, it's supposed to be there. While the cap is removed, make sure the vent screens are removed, (factory TSB). This will help ventillate the cap and reduce condensation inside the cap. Probably would be best to check camshaft retard, and adjust it if necessary. It's done with a scan tool capable of accessing the data stream.

Last edited by Captain Hook; 12-10-2012 at 05:48 PM.

#3

the rotor is definitally not contacting the cap. I have already checked the distributor bearing lash, i have also tried multiple brands of replacement parts including ac delco, and it had the same problem just as quick as the others, i have not tried the di-electric on the inside, but i am not really sure how that will help since the spark is aching out all over in the cap. What are these vent screen i should remove? i have been fighting with this problem for 3 years now

#4

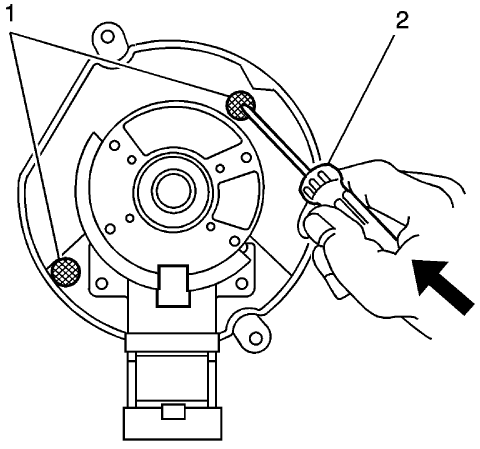

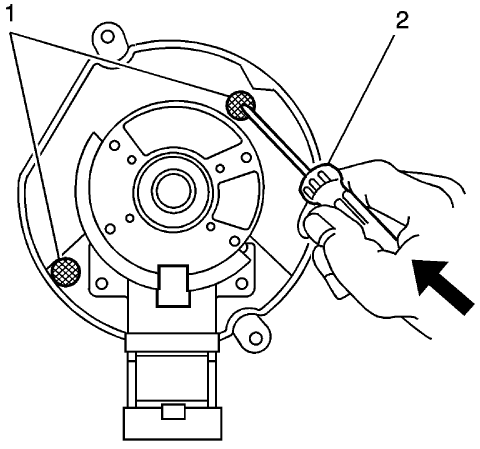

#1 in the image below are the vent screens, if they are restricted, condensation will accumulate on the under side of the cap. The moisture will promote crossfire. Originally GM advised to clean the screens, then they decided to remove them totally. If you've been having this problem for 3 years, camshaft retard may be out of spec. The adjustment aligns the rotor with the cap terminals, (among other things) to reduce/eliminate crossfire inside the cap. Camshaft retard directly affects ignition timing as well, which affects performance and fuel mileage. Desired spec is zero degrees with a tolerance of + or - 2 degrees. It can be off as much as ~27 degrees before it will set a DTC in memory and turn on the SES light. The data stream is viewed on a capable scan tool only. If the distributor has been removed, 99.9% chance the adjustment is incorrect.

Last edited by Captain Hook; 12-10-2012 at 06:54 PM.

#5

I am going to take a look at those two things tommorrow and replace the cap and rotor again.

Is the camshaft retard adjusted just like timing would be? My father is a ASE mechanic so he has acess to all the scan tools and computers i could possiably need. Do i need to unplug anything to read it like older distributors are or is it just read running at idle?

The vents i had no idea about and i was wondering how it was vented and was even considering drilling a vent into the cap. I can bet on the fact that mine are plugged.

#6

Make sure you install an AC Delco cap & rotor, (yes, it DOES make a difference on these engines) and put a dab of silicone dielectric grease on each terminal, inside and out.

Camshaft retard is only viewed on a capable scan tool. Nothing to plug in or unplug. Very simple operation, takes less than 5 minutes: Engine running at idle, snap throttle momentarily above 2000 RPM and back to idle, (must be done after making an adjustment so the reading is accurate). Desired spec is zero degrees + or - 2 degrees. It is adjusted by loosening the distributor hold down bolt and slightly rotating the distributor housing. The ID of the hole in the intake manifold is larger than the OD of the distributor, the "slop" allows for ~15 total degrees of adjustment. If you can't achieve zero degrees by rotating the distributor: Remove the distributor, remove the OEM distributor hold down bracket and discard it. Reinstall the distributor and install a SBC hold down bracket, (Mr. Gasket part #1009) available at most auto parts stores: Mr. Gasket Distributor Hold-Down Clamps 1009 - SummitRacing.com

This will make the distributor fully adjustable.

Some of the OEM distributor housings have a small "slit" instead of the screen. On those you can drill the holes out to approximately 1/4" to allow for ventilation.

Camshaft retard is only viewed on a capable scan tool. Nothing to plug in or unplug. Very simple operation, takes less than 5 minutes: Engine running at idle, snap throttle momentarily above 2000 RPM and back to idle, (must be done after making an adjustment so the reading is accurate). Desired spec is zero degrees + or - 2 degrees. It is adjusted by loosening the distributor hold down bolt and slightly rotating the distributor housing. The ID of the hole in the intake manifold is larger than the OD of the distributor, the "slop" allows for ~15 total degrees of adjustment. If you can't achieve zero degrees by rotating the distributor: Remove the distributor, remove the OEM distributor hold down bracket and discard it. Reinstall the distributor and install a SBC hold down bracket, (Mr. Gasket part #1009) available at most auto parts stores: Mr. Gasket Distributor Hold-Down Clamps 1009 - SummitRacing.com

This will make the distributor fully adjustable.

Some of the OEM distributor housings have a small "slit" instead of the screen. On those you can drill the holes out to approximately 1/4" to allow for ventilation.

#7

Oh crap! i never realised there was that much "slop" allowance in the distributor, always just put it back in where it origionally was. I have had it out a couple times too, the last time was because i had to do my lower intake gaskets. This has been very helpfull and i will be looking into it tonigh, i really appreciate all the help.

BTW, does any one else experience a scary bad ride on the highway? If i am doing 70+ with my blazer and hit a bump it dips and rocks back and forth like i am going to loose it. I have checked all the suspension parts, even put washers in the front sway bar to tighten up the slop in the rubber bushing links. The last thing i tried was very overkill and i wish i never did it because it completly ruined the ride quality, but i put extreme heavy duty shocks in, and that helped a lot but i still get a initial dip and then a rock back and forth, but with the big shocks it does not keep rocking like it used to. It quite honestly is very scary. But it is much better then when i had the monroe sense-a-trac shocks on it.

BTW, does any one else experience a scary bad ride on the highway? If i am doing 70+ with my blazer and hit a bump it dips and rocks back and forth like i am going to loose it. I have checked all the suspension parts, even put washers in the front sway bar to tighten up the slop in the rubber bushing links. The last thing i tried was very overkill and i wish i never did it because it completly ruined the ride quality, but i put extreme heavy duty shocks in, and that helped a lot but i still get a initial dip and then a rock back and forth, but with the big shocks it does not keep rocking like it used to. It quite honestly is very scary. But it is much better then when i had the monroe sense-a-trac shocks on it.

#8

Monroe Sense-a-trac and Relex shocks are pretty weak. The Monroe Mono Tube shocks give a much stiffer ride and better stability.

Check this stuff out and you'll probably find what's causing the scary ride Any one or more of these things could be causing it:

Any one or more of these things could be causing it:

Sway bar end links?

Sway bar isolators?

Upper and lower ball joints?

Upper and lower control arm bushings?

Front wheel bearing/hubs?

Pitman arm?

Idler arm?

Wheel alignment?

Tie rod ends?

Steering gear box preload?

Check this stuff out and you'll probably find what's causing the scary ride

Any one or more of these things could be causing it:

Any one or more of these things could be causing it:Sway bar end links?

Sway bar isolators?

Upper and lower ball joints?

Upper and lower control arm bushings?

Front wheel bearing/hubs?

Pitman arm?

Idler arm?

Wheel alignment?

Tie rod ends?

Steering gear box preload?

#9

Here is what i found with the distributor: I completly removed it so i could closly inspect it. I had the hole/slot style vents with no screens and nothing was blocking them, much to my suprise and dissipointment, but i drilled them out to a 11/4 inch anyways. My cam retard was at -12 degrees, i only had enough bolt play to adjust it to -10 degrees,m so i removed the bracket and drilled it out. My cam retard not sits at dead 0 with no change at all when driving :-)

As far as the suspension issue, the mono tube monroe is what i am running now, but they destroyedc ride quality. You know feel every single pothole right in the seat of your pants big time. And as far as checking/replacing, every part you have listed has been either checked, modified to make better, or replaced. I am almost wondering if it could be possiable that the torsions bars are weak???

As far as the suspension issue, the mono tube monroe is what i am running now, but they destroyedc ride quality. You know feel every single pothole right in the seat of your pants big time. And as far as checking/replacing, every part you have listed has been either checked, modified to make better, or replaced. I am almost wondering if it could be possiable that the torsions bars are weak???

#10

-12 degrees.... What that means is the gap between the rotor segment and the terminal in the cap was too large when the PCM commanded the ignition module to fire the coil. The larger the gap, the more likely it will crossfire inside the cap. It also skewed the data for misfire detection AND the ability for the PCM to acurately identify which cylinder was misfiring. How does it run now that cam retard is set correctly?

Weak torsion bars will allow the front chassis ride height to decrease. If it drops, (or increases) out of spec, it will cause handling issues and also wear out suspension & steering parts prematurely. Torsion bars can be adjusted to bring ride height back into specs if necessary. If you need the spec & procedure, just ask.

Weak torsion bars will allow the front chassis ride height to decrease. If it drops, (or increases) out of spec, it will cause handling issues and also wear out suspension & steering parts prematurely. Torsion bars can be adjusted to bring ride height back into specs if necessary. If you need the spec & procedure, just ask.