2001 Blazer Sticking Valve?????

#1

OK - My turn for a question....

2001 Blazer 4.3. Hard code P0304 (bought this vehicle with the SES light intentionally disabled as wire was disconnected and taped). Dang it, I simply loved the way it looked, and it only had 65K miles - what could be wrong???? I paid plenty! I know better!

Poor gas mileage - about 13 mpg Runs good and engine quiet when cold. Engine gets progressively noisier as it gets fully warmed up. Loud clicking at idle when completely warmed up. Noise much quieter and sometimes disappears with engine raised off of idle - then immediately comes back when allowed to idle. Do not feel a definite hard miss at any time, but in reality power seems down and ECU is probably picking up the misfire. Oil pressure not overly wonderful but in spec (min of 10 psi at 600RPM idle when hot up to 35psi at 2000 rpm when hot). Compression OK on #4 (same as #3).

I'm thinking #4 exhaust valve guide sticking (or possibly a weak/broken exhaust valve spring), causing valve to not quite fully close most of the time. This would allow a little exhaust to be drawn back into the #4 cylinder, causing enough of a misfire to set the code. It would also explain why when cold and rich it runs pretty good. But when hot the sticky valve could loosen up enough to suddenly snap closed during slow idle when there is more time and cause the strange ticking sound. Of course this is all pure speculation at this point.

What do you think? Anyone heard this before? It's definitely not your usual rocker noise. Sounds deep and in the front but not on a specific side.

Not truly wanting to tear things apart until next Spring. Bought it to use this winter in the snow and don't want to tear anything down right now as it will certainly function for me in bad weather. Just curious.

Here is the tick in all of it's glory. I believe there are few things with cars that are unique to a particular person's vehicle, and someone else has heard it all before in the same model. Take a listen and tell me what you think.

Thanks in advance,

Les

2001 Blazer 4.3. Hard code P0304 (bought this vehicle with the SES light intentionally disabled as wire was disconnected and taped). Dang it, I simply loved the way it looked, and it only had 65K miles - what could be wrong???? I paid plenty! I know better!

Poor gas mileage - about 13 mpg Runs good and engine quiet when cold. Engine gets progressively noisier as it gets fully warmed up. Loud clicking at idle when completely warmed up. Noise much quieter and sometimes disappears with engine raised off of idle - then immediately comes back when allowed to idle. Do not feel a definite hard miss at any time, but in reality power seems down and ECU is probably picking up the misfire. Oil pressure not overly wonderful but in spec (min of 10 psi at 600RPM idle when hot up to 35psi at 2000 rpm when hot). Compression OK on #4 (same as #3).

I'm thinking #4 exhaust valve guide sticking (or possibly a weak/broken exhaust valve spring), causing valve to not quite fully close most of the time. This would allow a little exhaust to be drawn back into the #4 cylinder, causing enough of a misfire to set the code. It would also explain why when cold and rich it runs pretty good. But when hot the sticky valve could loosen up enough to suddenly snap closed during slow idle when there is more time and cause the strange ticking sound. Of course this is all pure speculation at this point.

What do you think? Anyone heard this before? It's definitely not your usual rocker noise. Sounds deep and in the front but not on a specific side.

Not truly wanting to tear things apart until next Spring. Bought it to use this winter in the snow and don't want to tear anything down right now as it will certainly function for me in bad weather. Just curious.

Here is the tick in all of it's glory. I believe there are few things with cars that are unique to a particular person's vehicle, and someone else has heard it all before in the same model. Take a listen and tell me what you think.

Thanks in advance,

Les

Last edited by LesMyer; 10-14-2014 at 05:25 PM.

#2

Definitely a lifter. Oil pressure is a bit low.... These things are famous for leaky lower intake manifold gaskets, and if coolant gets into the oil, it thins it out, causes oil pressure to drop, and lifters will clatter.

If it turns out that it needs the gaskets, use Felpro MS98002T only.

If it turns out that it needs the gaskets, use Felpro MS98002T only.

#3

Definitely a lifter. Oil pressure is a bit low.... These things are famous for leaky lower intake manifold gaskets, and if coolant gets into the oil, it thins it out, causes oil pressure to drop, and lifters will clatter.

If it turns out that it needs the gaskets, use Felpro MS98002T only.

If it turns out that it needs the gaskets, use Felpro MS98002T only.

If it is oil pressure, I find it strange that the lifter bleeds down instantly from 35psi when rpm is dropped to idle from 2000 rpm. But stranger things have happened.

In any case thanks for your response. Any others?

Les

#4

I' do go with the captain here.....but, him and I have been chasing a p0301 in my blazer for awhile now.....sometimes would run perfect others not so much..... I say try a cyl leak down on that motor!!! That's how we discovered I have an issue that is valve guide related!!!!! There was a tab issued for these motors regarding tight valve guides......oil pressure does seem low, but also falls within GM specs...

I say try a cyl leak down on that motor!!! That's how we discovered I have an issue that is valve guide related!!!!! There was a tab issued for these motors regarding tight valve guides......oil pressure does seem low, but also falls within GM specs... I would like to believe such a low mileage motor would have much better pressure!!! Hell, my original motor had 170k from previous owner that never took care of it, and had better pressure @ idle before it grenaded

I would like to believe such a low mileage motor would have much better pressure!!! Hell, my original motor had 170k from previous owner that never took care of it, and had better pressure @ idle before it grenaded

I say try a cyl leak down on that motor!!! That's how we discovered I have an issue that is valve guide related!!!!! There was a tab issued for these motors regarding tight valve guides......oil pressure does seem low, but also falls within GM specs...

I say try a cyl leak down on that motor!!! That's how we discovered I have an issue that is valve guide related!!!!! There was a tab issued for these motors regarding tight valve guides......oil pressure does seem low, but also falls within GM specs...

#5

Definitely a lifter. Oil pressure is a bit low.... These things are famous for leaky lower intake manifold gaskets, and if coolant gets into the oil, it thins it out, causes oil pressure to drop, and lifters will clatter.

If it turns out that it needs the gaskets, use Felpro MS98002T only.

If it turns out that it needs the gaskets, use Felpro MS98002T only.

If that is the problem, sadly I think the engine may have already seen some damage.

Thanks again,

Les

#6

Any type of coolant will make the oil thin out when the engine is running. It usually doesn't get what I call "milky" though, just thin. When the oil/coolant mixture makes its way to the lifters, the lifters bleed down very rapidly and clatter. Increasing engine RPM increases the oil pressure and flow causing the clatter to decrease.

After the engine sets for 10 or 12 hours without being started, the coolant will separate from the oil and lay in the bottom of the oil pan. When you initially take the drain plug out, you'll get coolant first, then the oil. If its already in a drain pan, and you dump it out, you'll probably get a mixture of coolant and oil making it difficult to determine how much coolant is actually there. You might try dumping it into a plastic milk jug or washer solvent jug. After it sets, if there's any coolant in it, you'll see a definite line of oil & coolant.

After the engine sets for 10 or 12 hours without being started, the coolant will separate from the oil and lay in the bottom of the oil pan. When you initially take the drain plug out, you'll get coolant first, then the oil. If its already in a drain pan, and you dump it out, you'll probably get a mixture of coolant and oil making it difficult to determine how much coolant is actually there. You might try dumping it into a plastic milk jug or washer solvent jug. After it sets, if there's any coolant in it, you'll see a definite line of oil & coolant.

#7

OK I inspected and measured the oil in my oil drain pan. 4.5 quarts and no water separation after 1 week - so I'm going to assume no intake coolant leaks at this point in time. What I don't know..... because of recent engine detailing, is if intake gaskets have been replaced in the past (and coolant leak at intake might have caused bearing wear and the subsequent low oil pressure I am observing.

I really don't want to deal with engine out repairs before this winter, but I'm going to see if I can eliminate the Cylinder 4 miss (or at least eliminate some possible causes of the PO304) and diagnose things by replacing some parts I will certainly be replacing anyways at some point - and by inspection of valvetrain when apart. Admittedly a bit of a shotgun approach, but the expense of the parts is not so bad. Thanksgiving seems a good time to do it, as I have some vacation that week anyway.

So plan is to replace intake gaskets (with Felpro gasket set/new bolts) and pull valve covers/rockers for inspection of valve springs/valve guides/pushrods/lifters. If I shut the engine off when fully warm and fully clicking, I should be able to determine if a lifter has collapsed and if so which one it is. I can also see if there is significant valve guide wear and/or any weakened valve springs. If I find a bad spring or something else other than a bad valve guide, I will replace it. Also planning to upgrade to the MFI injectors and replace cap/rotor/wires/plugs while I'm at it - all AC Delco parts.

If I don't have a bad valve guide, I should hopefully come out with a engine that doesn't set the PO304 and gets better mileage. Of course I may still have an oil pressure problem. If so, I will cross that bridge when I come to it.

A couple of questions if I may...

Is there any reason why I can't lay a high quality straight edge across the distributor and scribe marks so the distributor can be put back in exactly in the same position? Wouldn't this eliminate the need to do the timing learn procedure?

Is there anything in the intake manifold that won't take the hot tank solution in a machine shop?

Thanks in advance,

LMyer

I really don't want to deal with engine out repairs before this winter, but I'm going to see if I can eliminate the Cylinder 4 miss (or at least eliminate some possible causes of the PO304) and diagnose things by replacing some parts I will certainly be replacing anyways at some point - and by inspection of valvetrain when apart. Admittedly a bit of a shotgun approach, but the expense of the parts is not so bad. Thanksgiving seems a good time to do it, as I have some vacation that week anyway.

So plan is to replace intake gaskets (with Felpro gasket set/new bolts) and pull valve covers/rockers for inspection of valve springs/valve guides/pushrods/lifters. If I shut the engine off when fully warm and fully clicking, I should be able to determine if a lifter has collapsed and if so which one it is. I can also see if there is significant valve guide wear and/or any weakened valve springs. If I find a bad spring or something else other than a bad valve guide, I will replace it. Also planning to upgrade to the MFI injectors and replace cap/rotor/wires/plugs while I'm at it - all AC Delco parts.

If I don't have a bad valve guide, I should hopefully come out with a engine that doesn't set the PO304 and gets better mileage. Of course I may still have an oil pressure problem. If so, I will cross that bridge when I come to it.

A couple of questions if I may...

Is there any reason why I can't lay a high quality straight edge across the distributor and scribe marks so the distributor can be put back in exactly in the same position? Wouldn't this eliminate the need to do the timing learn procedure?

Is there anything in the intake manifold that won't take the hot tank solution in a machine shop?

Thanks in advance,

LMyer

#8

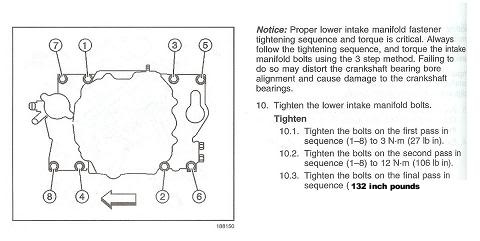

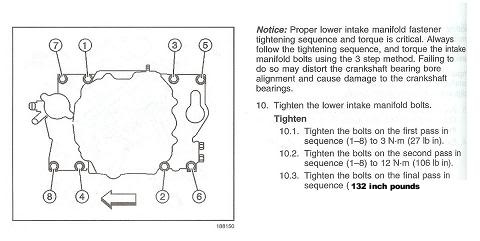

Intake gaskets: You do not need to replace the bolts. The threads on the bolts, and in both cylinder heads, must to be chased, (cleaned with a 5/16" X 18 tap & die). Thread sealer must be installed on the bolt threads prior to installation. Torque spec and tightening sequence is critical on this engine. Here's a "warning" straight from the GM shop manual:

"Is there any reason why I can't lay a high quality straight edge across the distributor and scribe marks so the distributor can be put back in exactly in the same position?"

What guarantee do you have that it's correct before you remove it? Regardless, it doesn't matter how careful you are, or how accurately you think you installed it, camshaft retard still needs to at least be checked with a capable scan tool. Cam retard can be off as much as ~26 degrees and not set any DTC's in memory, and you may or may not feel a misfire. If it's off by ~27 degrees or more, it will set P1345 in memory and illuminate the check engine light. P1345 means the distributor has been installed one or more teeth off. If camshaft retard is not within specs, there will be crossfire going on inside the distributor cap, guaranteed. I've installed distributors and adjusted camshaft retard on countless 4.3L engines. It's extremely rare to get cam retard within spec on the first try, so the scan tool gets connected on each one It's part of the job after installing the distributor. Check with Jeff, (07nhbpsi) I've done his twice, came real close both times, but not perfect.

It's part of the job after installing the distributor. Check with Jeff, (07nhbpsi) I've done his twice, came real close both times, but not perfect.

As long as you unbolt everything from the intake, hot tank is fine. I usually use a pressure washer and it does just fine.

"Is there any reason why I can't lay a high quality straight edge across the distributor and scribe marks so the distributor can be put back in exactly in the same position?"

What guarantee do you have that it's correct before you remove it? Regardless, it doesn't matter how careful you are, or how accurately you think you installed it, camshaft retard still needs to at least be checked with a capable scan tool. Cam retard can be off as much as ~26 degrees and not set any DTC's in memory, and you may or may not feel a misfire. If it's off by ~27 degrees or more, it will set P1345 in memory and illuminate the check engine light. P1345 means the distributor has been installed one or more teeth off. If camshaft retard is not within specs, there will be crossfire going on inside the distributor cap, guaranteed. I've installed distributors and adjusted camshaft retard on countless 4.3L engines. It's extremely rare to get cam retard within spec on the first try, so the scan tool gets connected on each one

It's part of the job after installing the distributor. Check with Jeff, (07nhbpsi) I've done his twice, came real close both times, but not perfect.

It's part of the job after installing the distributor. Check with Jeff, (07nhbpsi) I've done his twice, came real close both times, but not perfect.As long as you unbolt everything from the intake, hot tank is fine. I usually use a pressure washer and it does just fine.

#9

I'm going thru virtually the exact same thing. New(to me) 2000 2 dr. Jimmy with 90,000 miles threw a P0306 code. Compression on #6 was 40 PSI, others were 160+ IIRC. I pumped in a few squirts of oil and no change. I was committed that the head had to come off. # 4 exhaust valve was caked and held open by ~ 1/32" from all the gunk in there.

While the heads were out for rebuild, I pulled all the lifters and reconditioned them. They were BAD.

I never went thru the relearn, I checked the disty at TDC when I removed it. The rotor was pointed exactly toward the mark on the disty body. I made sure the engine was not moved during the "operation", When reassembled, the disty was replaced in the exact same position. Rotor still pointed directly at the housing mark.

Good luck at getting to the 4 ground bolts at the back of the heads! I ended up making a tool to tighten the last one down. Just no room from above or below.

Good luck!

While the heads were out for rebuild, I pulled all the lifters and reconditioned them. They were BAD.

I never went thru the relearn, I checked the disty at TDC when I removed it. The rotor was pointed exactly toward the mark on the disty body. I made sure the engine was not moved during the "operation", When reassembled, the disty was replaced in the exact same position. Rotor still pointed directly at the housing mark.

Good luck at getting to the 4 ground bolts at the back of the heads! I ended up making a tool to tighten the last one down. Just no room from above or below.

Good luck!

#10

Your tick is slow at idle which points to valvetrain, half engine RPM. A quick and dirty test...and i mean dirty...is to pull a valve cover and fire it up, you can push on the pushrod side of the lifter as its running and see if you can stop the tick, also look for any rockers that dont have ample oil squirting out of them or pooling up on them. You can lay a towel over them to start off with in case you get big squirts but they dont usually squirt too far. If you cant find anything loose in the upper part of the valvetrain then you may have a lifter sticking in its bore. Try dumping a half bottle of seafoam in the oil and run it for a few days.

Another possibility is that you have lost an oil galley plug from the front of the block and the lifter oil galley is puking into the timing cover, that may be why your oil pressure is low, incresed RPM gives enough flow to overcome the excess flow and pump the lifter. Unfortunately theres no way to check that without pulling the timing cover, or fishing around in the oil pan through the drain plug hole to see if you can find the little plug....good luck with that... The oil system in these engines is tried and trued for 50+ years, low pressure is not very common unless you have excessive wear In the bearings, but your video does not sound like bearing knock at all, normally that gets much worse as RPM goes up. Most ive seen tend to run at least 20 psi at idle and 40-50 at higher RPM. Hopefully you figure this out without too much headache, post back and let us know, i'm really curious as to what it is.

Another possibility is that you have lost an oil galley plug from the front of the block and the lifter oil galley is puking into the timing cover, that may be why your oil pressure is low, incresed RPM gives enough flow to overcome the excess flow and pump the lifter. Unfortunately theres no way to check that without pulling the timing cover, or fishing around in the oil pan through the drain plug hole to see if you can find the little plug....good luck with that... The oil system in these engines is tried and trued for 50+ years, low pressure is not very common unless you have excessive wear In the bearings, but your video does not sound like bearing knock at all, normally that gets much worse as RPM goes up. Most ive seen tend to run at least 20 psi at idle and 40-50 at higher RPM. Hopefully you figure this out without too much headache, post back and let us know, i'm really curious as to what it is.