Runs perfect then won't start, then runs perfect

#1

I have a '95 S10 with the vortex engine, 6 cylinder, OBDII 4.3.

I read the thread Rmblazernut started and that gave me some insite.

I get in it and it will just start up right off, drive all over and turn it off, then it will just roll over and over. If I wait a bit it will start. It was suggested I put a new module in the distributor and I did, I also put in a new pickup coil, new cap and rotor. I thought this might have something to do with the oil pressure shutting off my fuel pump so I put a new oil sending unit on. Seemed to correct the problem, but it does it again, just won't start, but give it a bit and it will start right up. I've checked spark, and put a pressure gauge on the service port and I'm getting about 61psi, but as I was reading rmblazernut thread, when I turn the key it pops up to 61psi then drops immediately, didn't know this was bad. My next move is to put my pressure gauge on the fuel pump line going into the fuel filter and see what I'm getting there.

Any other thoughts or suggestions?

I read the thread Rmblazernut started and that gave me some insite.

I get in it and it will just start up right off, drive all over and turn it off, then it will just roll over and over. If I wait a bit it will start. It was suggested I put a new module in the distributor and I did, I also put in a new pickup coil, new cap and rotor. I thought this might have something to do with the oil pressure shutting off my fuel pump so I put a new oil sending unit on. Seemed to correct the problem, but it does it again, just won't start, but give it a bit and it will start right up. I've checked spark, and put a pressure gauge on the service port and I'm getting about 61psi, but as I was reading rmblazernut thread, when I turn the key it pops up to 61psi then drops immediately, didn't know this was bad. My next move is to put my pressure gauge on the fuel pump line going into the fuel filter and see what I'm getting there.

Any other thoughts or suggestions?

Last edited by barnesto; 05-30-2014 at 01:06 PM.

#2

I tested the fuel pressure at the service port again, I don't think I had the gauge screwed down all the way the first time. I got about 61psi and it went down to 53psi in about 15 minutes. So this doesn't sound like a fuel problem I guess.

Any suggestions...

Any suggestions...

Last edited by barnesto; 05-30-2014 at 01:03 PM.

#3

Sounds like fuel delivery was OK when you checked it. It is possible that the check valve in the pump is not sealing every time though, best to check it several times to be sure.

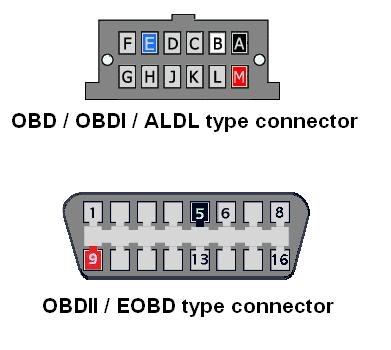

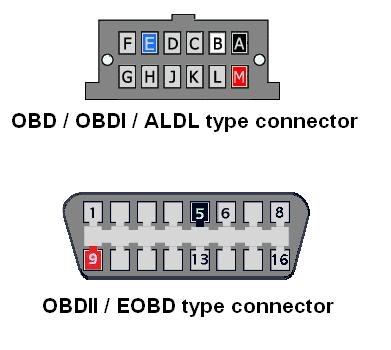

Before we go any further with diagnosis, 1995 4.3L Vortec had 3 different computer control systems and 2 different fuel injection systems. Specs & diagnostics are different so we need to know which one you have.

This one is CMFI, (Central Multiport Fuel Injection). It has OBDI or OBD1.5 computer controls, it is not fully OBDII compliant.

This one is CSFI, (Central Sequential Fuel Injection). It has fully compliant OBDII engine controls:

#2. Does the connector under the dash look like the top one, or the bottom one?

Before we go any further with diagnosis, 1995 4.3L Vortec had 3 different computer control systems and 2 different fuel injection systems. Specs & diagnostics are different so we need to know which one you have.

This one is CMFI, (Central Multiport Fuel Injection). It has OBDI or OBD1.5 computer controls, it is not fully OBDII compliant.

This one is CSFI, (Central Sequential Fuel Injection). It has fully compliant OBDII engine controls:

#2. Does the connector under the dash look like the top one, or the bottom one?

#4

The first photo of the engines is the one in my s10, the bottom OBD photo is the one in my s10.

I have a friend that owns an auto repair shop a few blocks from me and I took it over yesterday and he was going to put a scanner on it, but he said he wasn't getting anything, but he was connected or power from the Blazer. So I'm taking it over to another shop that is suppose to re-enter the information on my computer or something like that and do diagnostics while the truck is running.

I do have to say I have personally put in 5 or 6 fuel pumps in this Blazer in the last 11 years. Not sure why they go out so fast, I would guess about every 18 months. And it isn't fun putting one in. But I've gotten pretty good after 6 pump installs. I've been using the AC Delco brand the last 3 or so. So that might be an issue or the problem. I'm going to play with the fuel pressure this weekend. Now I haven't put the pressure gauge on when it is in the won't start mode yet, that would tell us more. But right now it is in the start right up stage. Funny...when you don't want it to start it starts...

I have a friend that owns an auto repair shop a few blocks from me and I took it over yesterday and he was going to put a scanner on it, but he said he wasn't getting anything, but he was connected or power from the Blazer. So I'm taking it over to another shop that is suppose to re-enter the information on my computer or something like that and do diagnostics while the truck is running.

I do have to say I have personally put in 5 or 6 fuel pumps in this Blazer in the last 11 years. Not sure why they go out so fast, I would guess about every 18 months. And it isn't fun putting one in. But I've gotten pretty good after 6 pump installs. I've been using the AC Delco brand the last 3 or so. So that might be an issue or the problem. I'm going to play with the fuel pressure this weekend. Now I haven't put the pressure gauge on when it is in the won't start mode yet, that would tell us more. But right now it is in the start right up stage. Funny...when you don't want it to start it starts...

#5

Your vehicle is a mid production 95 and uses OBD1.5 computer controls. It is a transition system from OBDI to OBDII. One of the requirements to be fully OBDII compliant, is that the PCM must be able to independently control each bank of injectors. Your engine has one fuel injector that feeds all 6 cylinders simultaneously. Most of the entry and mid level scan tools can't communicate with your system due to a unique communication protocol in your PCM.

Fuel pressure specs are: 55psi to 61psi (key on, engine off, fuel pump running). Pressure must remain above 50psi for at least 10 minutes after the pump shuts off. Your numbers of 61psi and 53psi are great, at least during the "start right up stage" Unfortunately, you pretty much need to test stuff when it doesn't start. There is a fairly common problem with the injector connector not making good contact at times. It can cause an intermittent no-start condition, along with other driveability issues. Might be worth removing the plenum and checking the connector and wiring.

Unfortunately, you pretty much need to test stuff when it doesn't start. There is a fairly common problem with the injector connector not making good contact at times. It can cause an intermittent no-start condition, along with other driveability issues. Might be worth removing the plenum and checking the connector and wiring.

If it's eating fuel pumps, there's definitely a problem with the vehicle wiring. AC Delco pumps are typically good for 100K miles... aftermarket pumps, maybe half that. A poor connection in the ground circuit for the pump motor will cause premature failure. Adding a 14ga wire from the module connector to a good clean body ground close to the module should solve the problem.

Fuel pressure specs are: 55psi to 61psi (key on, engine off, fuel pump running). Pressure must remain above 50psi for at least 10 minutes after the pump shuts off. Your numbers of 61psi and 53psi are great, at least during the "start right up stage"

Unfortunately, you pretty much need to test stuff when it doesn't start. There is a fairly common problem with the injector connector not making good contact at times. It can cause an intermittent no-start condition, along with other driveability issues. Might be worth removing the plenum and checking the connector and wiring.

Unfortunately, you pretty much need to test stuff when it doesn't start. There is a fairly common problem with the injector connector not making good contact at times. It can cause an intermittent no-start condition, along with other driveability issues. Might be worth removing the plenum and checking the connector and wiring. If it's eating fuel pumps, there's definitely a problem with the vehicle wiring. AC Delco pumps are typically good for 100K miles... aftermarket pumps, maybe half that. A poor connection in the ground circuit for the pump motor will cause premature failure. Adding a 14ga wire from the module connector to a good clean body ground close to the module should solve the problem.

#6

Adding the 14g a wire would replace the ground from the outside of the fuel tank to a good ground close? Or are you talking inside of the tank?

I have left the pressure gauge on the truck and have been testing it off and on throughout the weekend, but of course it just fires right up every time I have tested it. Maybe I need to find a reason to use it and then it won't start...Ha!

I have left the pressure gauge on the truck and have been testing it off and on throughout the weekend, but of course it just fires right up every time I have tested it. Maybe I need to find a reason to use it and then it won't start...Ha!

#7

Solder the 14ga wire to the vehicle harness connector as close as possible to the connector. Attach it to a suitable ground outside the tank, (not to the tank itself). Inspect the module connector for any melting of the connector, (deformed) and also check the pump terminals in the connector itself, they need to be clean and shiny. If you replaced the module connector, the connections need to be soldered, crimp connectors should NOT be used.

#8

Ok, let me see if I understand, get a 14ga wire. Not sure what you mean "harness connector" is that the place on top of the fuel pump? then find a nice clean spot for grounding it to the frame or body?

I have to say one time when I replaced the pump it had melting going on, can't remember if it was inside or on the connection on the top outside, a bit concerning thinking I'm going to blow up.

I've tested it all weekend, and just did again, and it fires right up....crap!

Seems like when I drive up to my gym, about 12 miles, that is when it starts. So maybe I need to drive it around and back home and see it that will do it.

I have to say one time when I replaced the pump it had melting going on, can't remember if it was inside or on the connection on the top outside, a bit concerning thinking I'm going to blow up.

I've tested it all weekend, and just did again, and it fires right up....crap!

Seems like when I drive up to my gym, about 12 miles, that is when it starts. So maybe I need to drive it around and back home and see it that will do it.

Last edited by barnesto; 06-01-2014 at 07:22 PM.

#9

Exactly, the harness connector is what plugs into the module on top of the tank. Depending on the style, it might have 2 or 4 wires in the connector. Grey is fuel pump feed, and black is the ground. If there are 2 black wires, connect both of them together and ground both of them.

#10

I'm putting in a used PCM, I think it is right under the glove box on this model. The mechanic thought it was under the instrument cluster on the drivers side. When I was changing the blend module on my heat and air which I had to remove the whole dash, there was something about 9"x6" and 2 to 3" deep right under my glove box. But not sure. Was going to find it to get some numbers so I get the correct part. Is this considered the computer that talks to everything, or am I going the wrong direction on this. The mechanic told me that I needed a new or replace the PCM. I'm guessing that is what controls or tells everything to do what it needs to do.

Last edited by barnesto; 06-03-2014 at 08:35 PM.