99 4.3 p0300 after overheat rebuild

#1

great site ,lots of info. I usually try and figure things out by just searching and reading posts ,but I have an issue that doesn't seem to fit the mold so far.

Little history- my wife has a 99 4.3 with 203,000 miles ,intake gaskets and heater core went about 2 years ago and i replaced them at that time as well as plugs ac delco 12 and bosch ultra premium 7mm wires ,ran great when done . However always seemed to loose a little coolant ,and was always rusty colored no matter how many flushes i did.

About 5 months ago ,I seemed to be loosing more and more coolant,no visible leaks ,no loss of power (temp got high but never overheated until recently.)

About 6 weeks ago it got to a point where i was adding coolant every other day and finally the leak showed up . Intake gaskets again .The next week the water pump let go on my wifes way to work , it overheated BAD, died and was towed home. Over the next 5 weeks ,I set out rebuilding the motor.

Present - I started it friday night , it runs rough at idle and revving .The ces light came up almost instantly after starting

The list of parts I replaced so far mainly because of the result of overheating or visible wear are :

remaned cylinder heads - originals cracked around bolt holes

lifters - 11 of the 12 had collapsed

push rods - didnt want to clean originals

timing chain - original seemed like it had play

timing chain cover - visible leaks plus i was told not to reinstall

oil pump and screen - had the oil pan off anyway and there was alot of sludge

ac delco plugs -platinum 41-942

cap and rotor no name brand- since put originals back on to diagnose

gasket set obviously

I have a vast majority of hand tools ,with a descent amount of mechanical knowledge but not many specialty tools.

Diagnostics so far -

pulled all spark plugs and found 1,3,and 5 carbon covered . Plugs 2,4,and 6 looked great . I pulled each individal wire off the cap whlie it was running , all had spark but cylinders 2,4,6 almost stalled the motor while 1,3,5 made no difference . I also pulled all spark plugs and checked for spark at the plug and seemed to be good on all cylinders.

After taking it to autozone for a code scan , I noticed the ces light starts flashing at exactly 28 mph and will continue until speed drops below 25 mph. the results of the code scan were p0300 and p0300 pending . I think because i never drove fast enough on the way to allow the pcm to perform all its own tests.I also rented a fuel pressure tester and the results were 64 psi pump on ,dropped to 60 after pump turned off ,and after 10 min. pressure was at 57 psi. thank you in advance for any help provided and sorry for the long post.

Little history- my wife has a 99 4.3 with 203,000 miles ,intake gaskets and heater core went about 2 years ago and i replaced them at that time as well as plugs ac delco 12 and bosch ultra premium 7mm wires ,ran great when done . However always seemed to loose a little coolant ,and was always rusty colored no matter how many flushes i did.

About 5 months ago ,I seemed to be loosing more and more coolant,no visible leaks ,no loss of power (temp got high but never overheated until recently.)

About 6 weeks ago it got to a point where i was adding coolant every other day and finally the leak showed up . Intake gaskets again .The next week the water pump let go on my wifes way to work , it overheated BAD, died and was towed home. Over the next 5 weeks ,I set out rebuilding the motor.

Present - I started it friday night , it runs rough at idle and revving .The ces light came up almost instantly after starting

The list of parts I replaced so far mainly because of the result of overheating or visible wear are :

remaned cylinder heads - originals cracked around bolt holes

lifters - 11 of the 12 had collapsed

push rods - didnt want to clean originals

timing chain - original seemed like it had play

timing chain cover - visible leaks plus i was told not to reinstall

oil pump and screen - had the oil pan off anyway and there was alot of sludge

ac delco plugs -platinum 41-942

cap and rotor no name brand- since put originals back on to diagnose

gasket set obviously

I have a vast majority of hand tools ,with a descent amount of mechanical knowledge but not many specialty tools.

Diagnostics so far -

pulled all spark plugs and found 1,3,and 5 carbon covered . Plugs 2,4,and 6 looked great . I pulled each individal wire off the cap whlie it was running , all had spark but cylinders 2,4,6 almost stalled the motor while 1,3,5 made no difference . I also pulled all spark plugs and checked for spark at the plug and seemed to be good on all cylinders.

After taking it to autozone for a code scan , I noticed the ces light starts flashing at exactly 28 mph and will continue until speed drops below 25 mph. the results of the code scan were p0300 and p0300 pending . I think because i never drove fast enough on the way to allow the pcm to perform all its own tests.I also rented a fuel pressure tester and the results were 64 psi pump on ,dropped to 60 after pump turned off ,and after 10 min. pressure was at 57 psi. thank you in advance for any help provided and sorry for the long post.

#2

If you replaced the intake gaskets with the same style as OEM, it's no wonder it leaked again, crappy design. Felpro gasket set MS98002T will not leak if clean up is done properly, and torque sequence and specs are followed to the letter, then flush & fill 50/50 Dexcool & distilled water.

When the intake gaskets leak coolant internally, after the engine sets overnight, coolant will separate from the oil and settle in the bottom of the oil pan, under the oil. If there's enough coolant in there, the oil pump pick up will be submerged in coolant. When the engine is started, the oil pump sucks the coolant and circulates it throughout the engine, (coolant is not a good lubricant ). The lifters will become noisy and eventually collapse. Eventually the oil & coolant mixture will destroy main bearings, rod bearings, cam bearings, crankshaft and camshaft, in other words, time for a new engine.

). The lifters will become noisy and eventually collapse. Eventually the oil & coolant mixture will destroy main bearings, rod bearings, cam bearings, crankshaft and camshaft, in other words, time for a new engine.

They instructed you correctly with the timing cover, if it is removed it must be replaced. There's another tid bit to go along with that: If the timing cover, and or crankshaft position sensor is moved, removed, replaced or disturbed in any way, the crankshaft position sensor relearn must be performed. It's done with a scan tool capable of initiating the relearn, (the el cheapo $300 or $400 scan tools can't do it). After the relearn, camshaft retard needs to be checked/adjusted as well. Without doing both of these, your P0300 is totally inacurate. (Otherwise the PCM would have identified cylinders 1, 3 & 5 as misfires.) Both sensors work together to detect cylinder misfire and identifying which cylinder(s) are misfiring.

Carbon fouled plugs 1, 3, & 5, could be due to a lazy or dead oxygen sensor on bank #1. A lazy sensor might not turn on the SES light or set a DTC in memory. Could also be due to crossfire in the distributor cap which could be a bad cap, worn bushings, worn drive gear, camshaft retard being incorrect, or any combination of these things.

On the bright side, fuel pressure and leakdown are both good!

When the intake gaskets leak coolant internally, after the engine sets overnight, coolant will separate from the oil and settle in the bottom of the oil pan, under the oil. If there's enough coolant in there, the oil pump pick up will be submerged in coolant. When the engine is started, the oil pump sucks the coolant and circulates it throughout the engine, (coolant is not a good lubricant

). The lifters will become noisy and eventually collapse. Eventually the oil & coolant mixture will destroy main bearings, rod bearings, cam bearings, crankshaft and camshaft, in other words, time for a new engine.

). The lifters will become noisy and eventually collapse. Eventually the oil & coolant mixture will destroy main bearings, rod bearings, cam bearings, crankshaft and camshaft, in other words, time for a new engine.They instructed you correctly with the timing cover, if it is removed it must be replaced. There's another tid bit to go along with that: If the timing cover, and or crankshaft position sensor is moved, removed, replaced or disturbed in any way, the crankshaft position sensor relearn must be performed. It's done with a scan tool capable of initiating the relearn, (the el cheapo $300 or $400 scan tools can't do it). After the relearn, camshaft retard needs to be checked/adjusted as well. Without doing both of these, your P0300 is totally inacurate. (Otherwise the PCM would have identified cylinders 1, 3 & 5 as misfires.) Both sensors work together to detect cylinder misfire and identifying which cylinder(s) are misfiring.

Carbon fouled plugs 1, 3, & 5, could be due to a lazy or dead oxygen sensor on bank #1. A lazy sensor might not turn on the SES light or set a DTC in memory. Could also be due to crossfire in the distributor cap which could be a bad cap, worn bushings, worn drive gear, camshaft retard being incorrect, or any combination of these things.

On the bright side, fuel pressure and leakdown are both good!

#3

thanks for the response, had a feeling about the crank sensor because of what i have been reading ,but was unsure because it seems half the engine is running right and the other not so much. I did check the part number of gaskets im currently using however it is for the whole head set HS 9354 PT-6 fel-pro ,dont have individual part number for intake gskets alone. I'm pretty sure i used fel-pro the last time however I didn't use any thread lock on the bolts and I noticed they backed out. What kind of shop is capable of the crank sensor relearn ? Hopefully not just the dealership. If it makes a difference I did use a delco timing cover.

I am in the process of rechecking underneath the upper plenum to make sure I put the crab assembly in correctly ,and i did notice the drivers side of both the upper and lower to be slightly wet with fuel. I didnt mention it before but when I took apart the engine a couple weeks ago there was alot of carbon or fuel deposits on both upper and lower plenums and on the crab assembly itself which I thoroughly cleaned with engine degreaser and carb cleaner.

is there anything else i can check now that ive taken it apart again ?

I am in the process of rechecking underneath the upper plenum to make sure I put the crab assembly in correctly ,and i did notice the drivers side of both the upper and lower to be slightly wet with fuel. I didnt mention it before but when I took apart the engine a couple weeks ago there was alot of carbon or fuel deposits on both upper and lower plenums and on the crab assembly itself which I thoroughly cleaned with engine degreaser and carb cleaner.

is there anything else i can check now that ive taken it apart again ?

#4

The relearn can be done by any shop that has a scan tool capable of initiating it. Call around, they'll be able to tell you if they can do it. Same thing with camshaft retard.

The crankshaft position sensor relearn, or lack of it being performed, will not cause misfires only on 1, 3, & 5, it will have the same affect on all 6 cylinders.

The Felpro HS 9354 PT-6 has the upgraded intake gaskets, metal & rubber sandwiched together. Stay away from the plastic & silicone rubber ones. The gasket set does not include new head bolts, which are necessary to do the job. The threads on the lower intake bolts, and in the cylinder heads, must chased with a tap & die to remove the old thread sealer. New sealer must be applied to the bolts, and torqued in sequence, to factory spec. If torque is too high, the block can be distorted. If torque is too low, or sealer is not applied, the bolts can "walk out". The holes in the cylinder heads are not blind holes, they are exposed to engine oil which will lube the bolts and allow them to "walk out" even quicker.

When the upper plenum is removed, there is a tube that is visible in the front of the lower intake manifold that points upward, then rearward. When the EGR valve opens, it fills the entire plenum with exhaust through that tube. The black carbon that you're cleaning off will return the first time you drive the vehicle, so don't waste too much time there The wet fuel, might be a result of the misfires, but not causing them.

The wet fuel, might be a result of the misfires, but not causing them.

The crankshaft position sensor relearn, or lack of it being performed, will not cause misfires only on 1, 3, & 5, it will have the same affect on all 6 cylinders.

The Felpro HS 9354 PT-6 has the upgraded intake gaskets, metal & rubber sandwiched together. Stay away from the plastic & silicone rubber ones. The gasket set does not include new head bolts, which are necessary to do the job. The threads on the lower intake bolts, and in the cylinder heads, must chased with a tap & die to remove the old thread sealer. New sealer must be applied to the bolts, and torqued in sequence, to factory spec. If torque is too high, the block can be distorted. If torque is too low, or sealer is not applied, the bolts can "walk out". The holes in the cylinder heads are not blind holes, they are exposed to engine oil which will lube the bolts and allow them to "walk out" even quicker.

When the upper plenum is removed, there is a tube that is visible in the front of the lower intake manifold that points upward, then rearward. When the EGR valve opens, it fills the entire plenum with exhaust through that tube. The black carbon that you're cleaning off will return the first time you drive the vehicle, so don't waste too much time there

The wet fuel, might be a result of the misfires, but not causing them.

The wet fuel, might be a result of the misfires, but not causing them.

#5

I didn't mention in original post parts I replaced that felt had no bearing on the issue but I did install new head bolts that had thread sealer on them . I also chased all threads and followed torque specs and sequences. And in addition I replaced all coolant hoses , oil cooler lines , pcv and all fluids . Heads were cracked but not in a location to allow coolant to mix with oil though, the machine shop i had taken them to told me it was leaking in the combustion chamber due to discoloration on the valves.

Much to my disliking ,I will take it to a shop to have those two procedures done . Is it safe to drive potentially 20 miles in the condition its in, considering the ses flashing to the repair shop ?

Much to my disliking ,I will take it to a shop to have those two procedures done . Is it safe to drive potentially 20 miles in the condition its in, considering the ses flashing to the repair shop ?

#6

It is possible for the intake gaskets to leak coolant into an intake port which would cause discoloration on the valves. Not likely to happen on cylinders 3 and 4 though, (center cylinders on each bank) as the coolant passages are located at each end of the lower intake. A leaking head gasket can leak externally or internally into the combustion chambers. If it leaks into a combustion chamber, you're likely going to have combustion pressure entering the cooling system as well, which usually blows a heater hose or the radiator. Coolant can be checked for hydrocarbons, and if present, would indicate a leaking head gasket. It's extremely rare for a head gasket to leak coolant into the oil. In general, head gasket failure is not common on 4.3's

When the SES light flashes, it's indicating a misfire that will damage the catalytic converter. Probably not a good idea to drive it. With cylinders 1, 3, & 5 pushing raw fuel out, you're liable to overheat & destroy the converter.

When the SES light flashes, it's indicating a misfire that will damage the catalytic converter. Probably not a good idea to drive it. With cylinders 1, 3, & 5 pushing raw fuel out, you're liable to overheat & destroy the converter.

#7

If the lack of a relearn would cause a misfire in all cylinders wouldn't there be something else causing this issue , dirty or leaking poppets or injectors or like u said o2 sensors ? Or is the relearn and retard check just an unavoidable part of diagnosing the problem ? This is the part thats frustrating cause I know I dont pretend to be the smartest person , but for half the cylinders to run good and the others to run like crap confuses me . I could have messed something up but I would think it would be consistent across all cylinders.

#8

The crankshaft position sensor, camshaft position sensor, TPS, timing chain, etc, all need to be set properly so the PCM has a "benchmark" to base it's calculations from. The PCM has no way of "knowing" if they are set correctly, so it "assumes" they are correct. It's up to the technician to make sure they're all correct. If any of them supply the PCM with incorrect or inacurate data, it will affect injector timing, injector pulse width, and ignition timing, along with incorrect transmission shift points. The PCM is a computer and the adage applies, junk in, junk out.

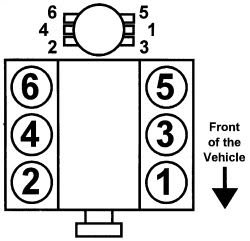

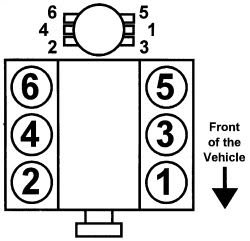

You're correct that the lack of a relearn will affect all cylinders equally and somethng else is causing 1, 3, & 5 to misfire. Could be an O2 sensor, mechanical distributor problem, incorrect camshaft retard etc etc. And yes, you could have "messed something up" but again, it most likely would affect all cylinders. Don't take offense to this, but is the distributor cap wired correctly? Look closely at Cyls 1, 3, & 5 on the cap:

You're correct that the lack of a relearn will affect all cylinders equally and somethng else is causing 1, 3, & 5 to misfire. Could be an O2 sensor, mechanical distributor problem, incorrect camshaft retard etc etc. And yes, you could have "messed something up" but again, it most likely would affect all cylinders. Don't take offense to this, but is the distributor cap wired correctly? Look closely at Cyls 1, 3, & 5 on the cap:

#9

I wont take offense at all , I am asking for help so I'll take what ever criticism comes positive or negative. yes the wires are on properly checked three times before and now once again. And part of the reason i pulled the upper plenum off again was to see if i put the poppets in the right holes, and i did. No guarantee they are spraying properly though.

#10

Well there again, it would be mighty coincidental if all 3 injectors on one bank were causing the problem  You can pretty much rule out primary ignition as well, (ignition coil, ignition module and PCM. The affected cylinders are every other one in the firing order BUT, they're all on the same side of the distributor cap which may indicate a bad cap, or at least crossfire, or as mentioned, the O2 sensor. The PCM monitors fuel mixture for each bank separately via the O2 sensors, but it can not identify cylinders in each bank, that's where the relearn and cam retard come into play. When one O2 sensor indicates rich, or lean, the injector pulse width is changed for all 3 cylinders on that bank simultaneously.

You can pretty much rule out primary ignition as well, (ignition coil, ignition module and PCM. The affected cylinders are every other one in the firing order BUT, they're all on the same side of the distributor cap which may indicate a bad cap, or at least crossfire, or as mentioned, the O2 sensor. The PCM monitors fuel mixture for each bank separately via the O2 sensors, but it can not identify cylinders in each bank, that's where the relearn and cam retard come into play. When one O2 sensor indicates rich, or lean, the injector pulse width is changed for all 3 cylinders on that bank simultaneously.

You can pretty much rule out primary ignition as well, (ignition coil, ignition module and PCM. The affected cylinders are every other one in the firing order BUT, they're all on the same side of the distributor cap which may indicate a bad cap, or at least crossfire, or as mentioned, the O2 sensor. The PCM monitors fuel mixture for each bank separately via the O2 sensors, but it can not identify cylinders in each bank, that's where the relearn and cam retard come into play. When one O2 sensor indicates rich, or lean, the injector pulse width is changed for all 3 cylinders on that bank simultaneously.

You can pretty much rule out primary ignition as well, (ignition coil, ignition module and PCM. The affected cylinders are every other one in the firing order BUT, they're all on the same side of the distributor cap which may indicate a bad cap, or at least crossfire, or as mentioned, the O2 sensor. The PCM monitors fuel mixture for each bank separately via the O2 sensors, but it can not identify cylinders in each bank, that's where the relearn and cam retard come into play. When one O2 sensor indicates rich, or lean, the injector pulse width is changed for all 3 cylinders on that bank simultaneously.