Low Compression-- need help!

#1

Need Help with Diagnosis--- Have about 30 lbs of compression in 5 of the 6 Cylinders of a 1996 Chevy Blazer 4.3L-- 70 lbs in cylinder 5

Background: This is a friend's Blazer that he ran hot-- originally tested it and it had anti- freeze running out of the water pump, the intake manifold(could be easily seen with pressure test) and the exhaust manifolds. Compression test showed low compression so decided the head gaskets were also bad. Did not run at this point. Decided to do a full upper gasket replacement with new water pump, plugs, wires, and dist. cap & rotor. Was told it would be highly unlikely the bottom end would be bad as these motors are pretty solid at that end, so decided to take the chance not rebuilding the whole thing. The Blazer has 226k miles, but in pretty solid shape.

After replacing everything and confirming the distributor is in correctly-- it would not start. Fuel pressure stays steady at 60 lbs and has good spark. Decided to pull the spark plugs and do another compression test and it only has 30 lbs of compression in each cylinder except for cylinder 5 with 70 lbs.

So did the piston rings get fried when it was run hot? I was also told it could possibly be the lifters and they need to be manually bleed? If so, how and why? They were never taken out. I did try and squirt some oil in each spark plug hole (wet test) to see if that would have an impact on the compression test, but it did not. ANY OTHER IDEAS?

Background: This is a friend's Blazer that he ran hot-- originally tested it and it had anti- freeze running out of the water pump, the intake manifold(could be easily seen with pressure test) and the exhaust manifolds. Compression test showed low compression so decided the head gaskets were also bad. Did not run at this point. Decided to do a full upper gasket replacement with new water pump, plugs, wires, and dist. cap & rotor. Was told it would be highly unlikely the bottom end would be bad as these motors are pretty solid at that end, so decided to take the chance not rebuilding the whole thing. The Blazer has 226k miles, but in pretty solid shape.

After replacing everything and confirming the distributor is in correctly-- it would not start. Fuel pressure stays steady at 60 lbs and has good spark. Decided to pull the spark plugs and do another compression test and it only has 30 lbs of compression in each cylinder except for cylinder 5 with 70 lbs.

So did the piston rings get fried when it was run hot? I was also told it could possibly be the lifters and they need to be manually bleed? If so, how and why? They were never taken out. I did try and squirt some oil in each spark plug hole (wet test) to see if that would have an impact on the compression test, but it did not. ANY OTHER IDEAS?

#2

It is a possibility .Does it smoke from that bank into the exhaust? There is a blow by test and i know there is a post around here on how to do this. It is the only way to really determine what the cause is. It can also be a bent valve, most likely an exhaust valve due to the overheating. If the valve will not seat properly it cannot build proper compression.

#3

When the heads were off everything looked good. I had the heads re-surfaced and they said everything looked ok, so I just re-installed the heads. I can't get the vehicle started because the compression is so low. All of the cylinders have low compression and if it was the valves then wouldn't all of the valves be bad. Just trying to eliminate one by one what it could be-- I appreciate your ideas!

#4

When you resurfaced the heads you have to consider everything has changed, from the length of the push rods, to the mounting of the intake manifold. I would turn the crank to top dead center, take a valve cover off and unbolt the rockers intake/exhaust on one of the cylinders that is low, this ensures that the valves are fully closed. do a compression test, if it`s changed to the good, then it`s your rods. if not it`s still bad, I would remove the heads again and use a true straight edge and check for uneven surface, just incase they did not do it correctly.

When you had the heads off, did you check the cylinder walls for scorching, grooves, etc.,? That's one way to tell if rings are burnt or bad, and/or cylinder walls are shot.

When you had the heads off, did you check the cylinder walls for scorching, grooves, etc.,? That's one way to tell if rings are burnt or bad, and/or cylinder walls are shot.

Last edited by Gambit66; 03-25-2015 at 03:42 AM.

#5

When the heads were off the cylinder walls and the pistons all looked good and that is why I decided it should be ok just to install the heads with the new gaskets.

I did loosen the rockers to see if the compression numbers would go up and it did for at least one of the cylinders. I got the same advice from a few other engine builders. They thought the push rods could be too tight because the lifters have not bled out and that once started they would balance out.

Even after I loosened the rockers to allow the valves to fully close, I still could not get enough compression for it to start.

Any other ideas?

I did loosen the rockers to see if the compression numbers would go up and it did for at least one of the cylinders. I got the same advice from a few other engine builders. They thought the push rods could be too tight because the lifters have not bled out and that once started they would balance out.

Even after I loosened the rockers to allow the valves to fully close, I still could not get enough compression for it to start.

Any other ideas?

#6

Did you check compression with the throttle propped open and all spark plugs removed? Did you do a wet and a dry compression test? Did the timing chain jump a tooth or two? You can check slack without any engine disassembly.

#7

I did the compression test with all of the plugs out and the throttled propped open with a screwdriver. I also did the wet and dry compression test. No improvement with the wet test.

How do I check the slack on the timing chain without taking the cover off?

How do I check the slack on the timing chain without taking the cover off?

#9

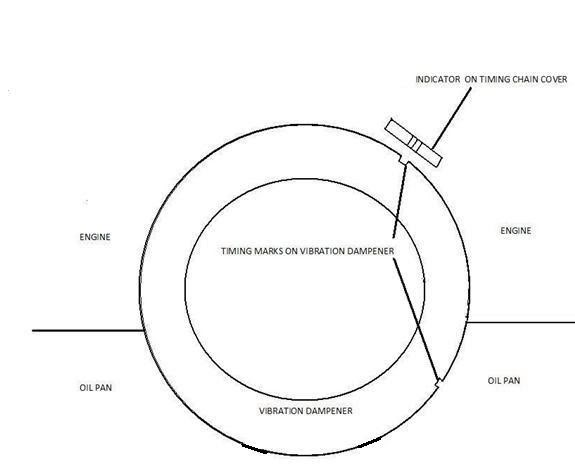

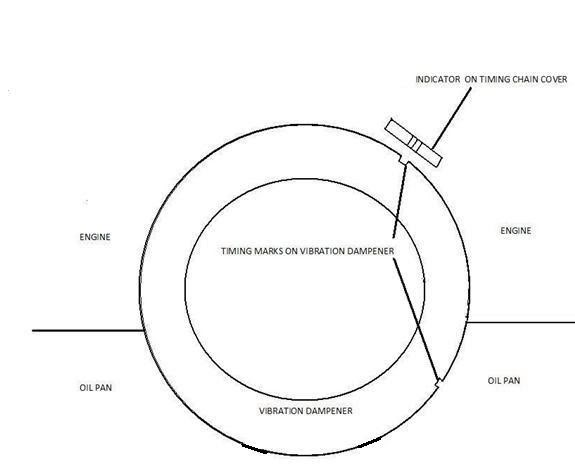

Remove the distributor cap to expose the rotor. Using a socket and ratchet on the crankshaft bolt, slowly rotate the crankshaft clockwise until the marks on the vibration dampener are aligned like this:

DO NOT rotate the crankshaft counter clockwise while aligning the marks, not even a little bit If you pass the mark, rotate another revolution clockwise. The object here is to keep all chain slack on the left side, as you're looking at it.

If you pass the mark, rotate another revolution clockwise. The object here is to keep all chain slack on the left side, as you're looking at it.

Have an assistant watch the rotor, (or place a hand on it) while you slowly rotate the crankshaft counter clockwise. The instant the rotor begins to move, stop rotating the crankshaft. If the timing mark on the dampener moved ~3/4" or more, the chain may have jumped time. If/when this happens, valve timing becomes retarded, and compression decreases.

DO NOT rotate the crankshaft counter clockwise while aligning the marks, not even a little bit

If you pass the mark, rotate another revolution clockwise. The object here is to keep all chain slack on the left side, as you're looking at it.

If you pass the mark, rotate another revolution clockwise. The object here is to keep all chain slack on the left side, as you're looking at it. Have an assistant watch the rotor, (or place a hand on it) while you slowly rotate the crankshaft counter clockwise. The instant the rotor begins to move, stop rotating the crankshaft. If the timing mark on the dampener moved ~3/4" or more, the chain may have jumped time. If/when this happens, valve timing becomes retarded, and compression decreases.

Last edited by Captain Hook; 03-31-2015 at 10:14 PM.