1996 4.3 Timing issue

#1

This is a 1996 S10 with the 4.3 Vortec. I've got an issue with timing where my torque app is showing -15-40 degrees timing depending on how the engine is revved. That's negative degrees. I have no misfire codes and no obvious misfires.

This is the 96 model which does not have the ability to move the distributor to set the timing. According to the FSM, the computer controls timing. I've elongated the bolt hole for the distributor hold down bolt and tired rotating the distributor a few degrees, but regardless of where I put it, the timing goes to the same negative values, indicating to me that the computer is controlling the timing. I do not see a pid for cam retard on my Car Gauge Pro app. I had used that app to set cam retard on a 98 5.7 vortec in the past.

From what I've read the cam and crank position sensor set timing. I've read a bunch of posts that talk about a crank sensor relearn whenever the crank sensor is removed or distributed and that the position of the sensor is written into the ECU. I've got the paper FSM for this vehicle and cannot not find an reference to such a relearn being necessary on the 1996 model year. There is a NAPA bulliten I found on the itnerweb that says it is necessary on the 1996 model. Other sources say the relearn process began in 1997. Some say even later dates than that.

Since the timing appears to be so far off, I'm wondering if the sensor had been removed or replaced at some point and that the relearn not performed. That assumes that there is such a thing a a crank relearn for this model year, which is what I'm trying to figure out.

Thanks.

This is the 96 model which does not have the ability to move the distributor to set the timing. According to the FSM, the computer controls timing. I've elongated the bolt hole for the distributor hold down bolt and tired rotating the distributor a few degrees, but regardless of where I put it, the timing goes to the same negative values, indicating to me that the computer is controlling the timing. I do not see a pid for cam retard on my Car Gauge Pro app. I had used that app to set cam retard on a 98 5.7 vortec in the past.

From what I've read the cam and crank position sensor set timing. I've read a bunch of posts that talk about a crank sensor relearn whenever the crank sensor is removed or distributed and that the position of the sensor is written into the ECU. I've got the paper FSM for this vehicle and cannot not find an reference to such a relearn being necessary on the 1996 model year. There is a NAPA bulliten I found on the itnerweb that says it is necessary on the 1996 model. Other sources say the relearn process began in 1997. Some say even later dates than that.

Since the timing appears to be so far off, I'm wondering if the sensor had been removed or replaced at some point and that the relearn not performed. That assumes that there is such a thing a a crank relearn for this model year, which is what I'm trying to figure out.

Thanks.

#2

The Car Gauge Pro only works on 1998+ for Cam Sensor Retard. 1996 and 1997 you would need to use Dash Command and buy the Enhanced PIDs for your year vehicle.

PCM determines timing based on inputs from a lot of sensors (primarily crank sensor), but Cam Sensor is not one of them. PCM uses cam sensor input to time sequential injector pulses with the engine firing order. Vehicle will even run with the cam sensor disconnected, but will pulse injectors in banks and turn on the SES light. Because cam sensor is in the distributor, the cam sensor also allows us to check rotor position relative to design specs (not actual rotor position) - but that does not mean the PCM is using it for any kind of ignition timing.

Timing range of -15° to -40° sounds about right (define minus as BTDC). -40 should be light or no load°. - 15° should be when engine is under heavy load (accelerating wide open throttle).

Crank relearn stores information regarding the normal response and timing of your particular crank sensor as the reluctor goes past it during a normal cylinder firing. If the computer sees the actual crank sensor response varying from what is stored, it interprets a lag or difference on a cylinder as a misfire and can even tell you which cylinder if it is a regular misfire. Yes, relearn is necessary on your vehicle if the crank sensor is disturbed or replaced.

If you want to know if your crank sensor relearn is valid, just pull a plug wire and do a functional test. Your Torque App should show a misfire on that cylinder.

I think you are worrying about non-issues, but now that you have elongated the bolt hole in the hold-down and have turned the distributor, you really should check the cam sensor retard value or you may develop misfires in the future (caps can start to track to the wrong terminals as they get older)!!

Good luck and best wishes.

PCM determines timing based on inputs from a lot of sensors (primarily crank sensor), but Cam Sensor is not one of them. PCM uses cam sensor input to time sequential injector pulses with the engine firing order. Vehicle will even run with the cam sensor disconnected, but will pulse injectors in banks and turn on the SES light. Because cam sensor is in the distributor, the cam sensor also allows us to check rotor position relative to design specs (not actual rotor position) - but that does not mean the PCM is using it for any kind of ignition timing.

Timing range of -15° to -40° sounds about right (define minus as BTDC). -40 should be light or no load°. - 15° should be when engine is under heavy load (accelerating wide open throttle).

Crank relearn stores information regarding the normal response and timing of your particular crank sensor as the reluctor goes past it during a normal cylinder firing. If the computer sees the actual crank sensor response varying from what is stored, it interprets a lag or difference on a cylinder as a misfire and can even tell you which cylinder if it is a regular misfire. Yes, relearn is necessary on your vehicle if the crank sensor is disturbed or replaced.

If you want to know if your crank sensor relearn is valid, just pull a plug wire and do a functional test. Your Torque App should show a misfire on that cylinder.

I think you are worrying about non-issues, but now that you have elongated the bolt hole in the hold-down and have turned the distributor, you really should check the cam sensor retard value or you may develop misfires in the future (caps can start to track to the wrong terminals as they get older)!!

Good luck and best wishes.

Last edited by LesMyer; 01-18-2018 at 01:56 PM.

#3

Les,

Thank you for your response and input. It is very helpful. The car is running with adequate power, but I was asking about fuel trim issues and P0171 and P0174 codes on another forum and universally got told my timing was bad and needed to be fixed before approaching fuel trims.

If you've got any input on the fuel trim issue, I'd love to hear it. This is a 96 with 82,000 miles. I'm getting lean codes after a few days, but the trims are generally pumping more fuel into the system. About as low as it will go is 6.2 (on each bank) at idle. Often, I'll see trims well over 25 when you combine the ST and LT trims. I've changed the MAF with a known good sensor. I've sprayed numerous cans of brake cleaner looking for leaks. I've smoked the intake a number of times. I was getting a little smoke out of the intake where the resonator connects, but I never heard the engine race or saw the fuel trims change wile spraying brake clean. I've pinched off the vacuum line to the brake booster and vacuum resorvoir with no change. I've changed out the pcv valve and hose. My IAC was clicking with the key on and engine off, so I swapped that out with another. I'm as certain as I can be that there is no vacuum leak, but if I spray the brake clean into the intake, the O2 sensors go high and the fuel trims drop. The three O2 sensors are new and seem to be modulating up and down fine. Fuel pressure is 58 psi and its got a new fuel pump.

I don't know what else it could be except for stuck injectors. I had thought that this was not the case because the LTFT was generally the same on both banks. Recently, they've started to vary. I've got the updated spider and injectors on order and will install that to see if it makes a difference, but I'm not sure what could be causing the issue. I don't suppose anyone else did either and that's why they were pointing to timing.

I've you've got any suggestions, I'd appreciate hearing them. Thanks.

Jim.

Thank you for your response and input. It is very helpful. The car is running with adequate power, but I was asking about fuel trim issues and P0171 and P0174 codes on another forum and universally got told my timing was bad and needed to be fixed before approaching fuel trims.

If you've got any input on the fuel trim issue, I'd love to hear it. This is a 96 with 82,000 miles. I'm getting lean codes after a few days, but the trims are generally pumping more fuel into the system. About as low as it will go is 6.2 (on each bank) at idle. Often, I'll see trims well over 25 when you combine the ST and LT trims. I've changed the MAF with a known good sensor. I've sprayed numerous cans of brake cleaner looking for leaks. I've smoked the intake a number of times. I was getting a little smoke out of the intake where the resonator connects, but I never heard the engine race or saw the fuel trims change wile spraying brake clean. I've pinched off the vacuum line to the brake booster and vacuum resorvoir with no change. I've changed out the pcv valve and hose. My IAC was clicking with the key on and engine off, so I swapped that out with another. I'm as certain as I can be that there is no vacuum leak, but if I spray the brake clean into the intake, the O2 sensors go high and the fuel trims drop. The three O2 sensors are new and seem to be modulating up and down fine. Fuel pressure is 58 psi and its got a new fuel pump.

I don't know what else it could be except for stuck injectors. I had thought that this was not the case because the LTFT was generally the same on both banks. Recently, they've started to vary. I've got the updated spider and injectors on order and will install that to see if it makes a difference, but I'm not sure what could be causing the issue. I don't suppose anyone else did either and that's why they were pointing to timing.

I've you've got any suggestions, I'd appreciate hearing them. Thanks.

Jim.

#4

Jim, a PO171 and PO174 code means that both banks were too lean. Maybe this reference will help some.

https://blazerforum.com/forum/diagno...plained-35154/

STFT values displayed through Bluetooth OBD2 device can be misleading (especially snapshots). STFTs cycle rapidly back and forth across 0%, just like O2 sensor voltages swing rapidly back and forth across 0.45V. Your o2 sensor voltages swinging implies that the STFT is also swinging just as much. The code and light means that the AVERAGE value for STFT, taken over 120 seconds, has exceeded the allowable limit.

Best way I know to monitor STFT is to plot it and observe when it is cycling abnormally high - or is pegged. I know you can do that with Car Gauge Pro. If you can't connect on your 1996 using "GM" - then use OBD2 Generic mode. STFT is in that one. You also might be able to plot in Torque, but I don't personally know how to do that. You will need to catch it in the act - that seems to be the biggest problem facing you. You don't know when it is happening for sure.

Please try that and report.

ps. a stuck injector would cause a misfire on a particular cylinder.

pps. Systems with the original poppet injectors are particularly subject to fuel pressure problems. Which do you have?

https://blazerforum.com/forum/diagno...plained-35154/

STFT values displayed through Bluetooth OBD2 device can be misleading (especially snapshots). STFTs cycle rapidly back and forth across 0%, just like O2 sensor voltages swing rapidly back and forth across 0.45V. Your o2 sensor voltages swinging implies that the STFT is also swinging just as much. The code and light means that the AVERAGE value for STFT, taken over 120 seconds, has exceeded the allowable limit.

Best way I know to monitor STFT is to plot it and observe when it is cycling abnormally high - or is pegged. I know you can do that with Car Gauge Pro. If you can't connect on your 1996 using "GM" - then use OBD2 Generic mode. STFT is in that one. You also might be able to plot in Torque, but I don't personally know how to do that. You will need to catch it in the act - that seems to be the biggest problem facing you. You don't know when it is happening for sure.

Please try that and report.

ps. a stuck injector would cause a misfire on a particular cylinder.

pps. Systems with the original poppet injectors are particularly subject to fuel pressure problems. Which do you have?

Last edited by LesMyer; 01-16-2018 at 02:06 PM.

#5

Soo, to summarize , you're trying to chase down the cause of the P0171 and P0174 codes that are being thrown?

I can tell you've been doing this stuff for a while, because those of us who have usually start by explaining everything we have done , but barely discuss what the original issue is...lol..

Anyways, now that we know what the symptom is, maybe they'll be some new directions to go and things to try..

Only 2 things I can think of at the moment. LIM gasket leak , or a exhaust leak,,I think you've covered most everything else.

I can tell you've been doing this stuff for a while, because those of us who have usually start by explaining everything we have done , but barely discuss what the original issue is...lol..

Anyways, now that we know what the symptom is, maybe they'll be some new directions to go and things to try..

Only 2 things I can think of at the moment. LIM gasket leak , or a exhaust leak,,I think you've covered most everything else.

#6

I know its kind of an odd way to have started off, but I was getting hammered on the timing so much on another forum that I thought it must be the the key to the problem. I don't have any exhaust leak (truck is very quiet and the fuel trim values are the same or very similar on both banks, so that pretty much rules out an exhaust leak, unless its at the Y pipe, but I'm in Texas and there's no rust or damage to the exhaust. I agree that a leaking manifold is the prime suspect, except that there is no evidence of a leak after 5 cans of brake clean and 3 instances of smoking the intake. Fuel pressure is 58. It is steady at idle and increases with snap throttle. I've driven around with the gauge on the windshield and it doesn't drop off.

Les, I get what you're saying about the fuel trims, but I'm graphing them with Torque. I can see the graph on the ST trims dropping when I goose the throttle. (I'm not sure if my "graphing" and your "plotting" are the same.) The graphs also decrease immediately if I spray brake clean into the intake with the motor running. I don't see them bouncing up and down in step with the O2 sensors. I get a smooth graph on the fuel trims for the most part. I've got a wired OBDII scanner that will read the trims and graph, and its the same as in Torque. When the car is cold ( and in closed loop), the fuel trims seem better. When the vehicle gets warmer, the trims go up. After changing the IAC yesterday, my ST trims would go to 0 at a stop light, which was a step in the right direction. Both LT trims were at 6.2 at the light. When driving and and the vehicle is warm, the LT and ST trims are all over the place, but never do the LT and ST trims zero out. I have seen the LT trims see saw 2-4% over second or two a couple of times while under the hood. I thought that extremely odd since it was the long term trims and not the short term trims bouncing up and down fairly rapidly. I thought I was watching a leak (and maybe I was), but it went away and was not affected by the brake cleaner.

Given that LT trims seem to start at 6.2 for each bank, I disconnected the battery to let it clear clear the memory. I'll see tonight if it goes to the same values and behavior after being run for a while.

Les, I get what you're saying about the fuel trims, but I'm graphing them with Torque. I can see the graph on the ST trims dropping when I goose the throttle. (I'm not sure if my "graphing" and your "plotting" are the same.) The graphs also decrease immediately if I spray brake clean into the intake with the motor running. I don't see them bouncing up and down in step with the O2 sensors. I get a smooth graph on the fuel trims for the most part. I've got a wired OBDII scanner that will read the trims and graph, and its the same as in Torque. When the car is cold ( and in closed loop), the fuel trims seem better. When the vehicle gets warmer, the trims go up. After changing the IAC yesterday, my ST trims would go to 0 at a stop light, which was a step in the right direction. Both LT trims were at 6.2 at the light. When driving and and the vehicle is warm, the LT and ST trims are all over the place, but never do the LT and ST trims zero out. I have seen the LT trims see saw 2-4% over second or two a couple of times while under the hood. I thought that extremely odd since it was the long term trims and not the short term trims bouncing up and down fairly rapidly. I thought I was watching a leak (and maybe I was), but it went away and was not affected by the brake cleaner.

Given that LT trims seem to start at 6.2 for each bank, I disconnected the battery to let it clear clear the memory. I'll see tonight if it goes to the same values and behavior after being run for a while.

#8

I know its kind of an odd way to have started off, but I was getting hammered on the timing so much on another forum that I thought it must be the the key to the problem. I don't have any exhaust leak (truck is very quiet and the fuel trim values are the same or very similar on both banks, so that pretty much rules out an exhaust leak, unless its at the Y pipe, but I'm in Texas and there's no rust or damage to the exhaust. I agree that a leaking manifold is the prime suspect, except that there is no evidence of a leak after 5 cans of brake clean and 3 instances of smoking the intake. Fuel pressure is 58. It is steady at idle and increases with snap throttle. I've driven around with the gauge on the windshield and it doesn't drop off.

Les, I get what you're saying about the fuel trims, but I'm graphing them with Torque. I can see the graph on the ST trims dropping when I goose the throttle. (I'm not sure if my "graphing" and your "plotting" are the same.) The graphs also decrease immediately if I spray brake clean into the intake with the motor running. I don't see them bouncing up and down in step with the O2 sensors. I get a smooth graph on the fuel trims for the most part. I've got a wired OBDII scanner that will read the trims and graph, and its the same as in Torque. When the car is cold ( and in closed loop), the fuel trims seem better. When the vehicle gets warmer, the trims go up. After changing the IAC yesterday, my ST trims would go to 0 at a stop light, which was a step in the right direction. Both LT trims were at 6.2 at the light. When driving and and the vehicle is warm, the LT and ST trims are all over the place, but never do the LT and ST trims zero out. I have seen the LT trims see saw 2-4% over second or two a couple of times while under the hood. I thought that extremely odd since it was the long term trims and not the short term trims bouncing up and down fairly rapidly. I thought I was watching a leak (and maybe I was), but it went away and was not affected by the brake cleaner.

Given that LT trims seem to start at 6.2 for each bank, I disconnected the battery to let it clear clear the memory. I'll see tonight if it goes to the same values and behavior after being run for a while.

Les, I get what you're saying about the fuel trims, but I'm graphing them with Torque. I can see the graph on the ST trims dropping when I goose the throttle. (I'm not sure if my "graphing" and your "plotting" are the same.) The graphs also decrease immediately if I spray brake clean into the intake with the motor running. I don't see them bouncing up and down in step with the O2 sensors. I get a smooth graph on the fuel trims for the most part. I've got a wired OBDII scanner that will read the trims and graph, and its the same as in Torque. When the car is cold ( and in closed loop), the fuel trims seem better. When the vehicle gets warmer, the trims go up. After changing the IAC yesterday, my ST trims would go to 0 at a stop light, which was a step in the right direction. Both LT trims were at 6.2 at the light. When driving and and the vehicle is warm, the LT and ST trims are all over the place, but never do the LT and ST trims zero out. I have seen the LT trims see saw 2-4% over second or two a couple of times while under the hood. I thought that extremely odd since it was the long term trims and not the short term trims bouncing up and down fairly rapidly. I thought I was watching a leak (and maybe I was), but it went away and was not affected by the brake cleaner.

Given that LT trims seem to start at 6.2 for each bank, I disconnected the battery to let it clear clear the memory. I'll see tonight if it goes to the same values and behavior after being run for a while.

I'll post some screen shots of various sensor/parameters I took at both idle and steady cruise down street/highway. Maybe you can ID something odd in yours that might help. Mine was running just fine at the time (I did it for someone else). Mine is a 2001, but should be pretty close.

#9

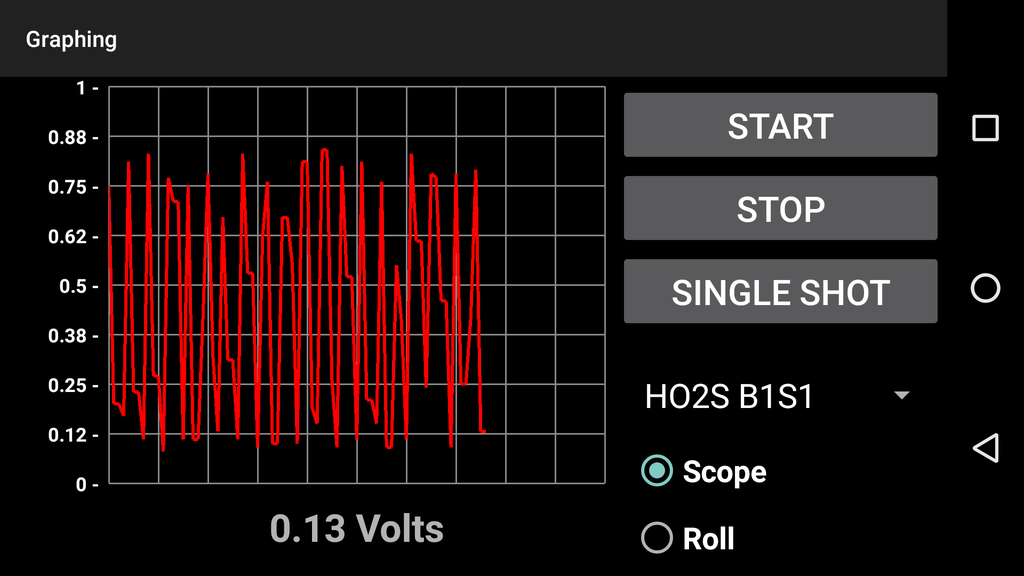

Here's a screen shot of my Torque page showing the O2 sensors and the LT and ST fuel trims. It started doing the see saw thing pretty clearly on the LT trims last night. I have no explanation as to what is going on because I'd expect to see the ST trims jumping around. I'm still not convinced its not the IAC. This see saw effect seems much worse than when I had the old IAC installed.

#10

at 2000 rpm O2 sensor cycles back and forth much more rapidly

At Idle

Time scale here is maybe 5-10 seconds for each plot. Note that O2 sensor reading can vary greatly depending on when the reading is taken (you already know this - comment is for other people). O2 sensor is averaging around the 0.45V at both RPMS (as it should if correctly controlling fuel mix).

Seems pretty strange that your STFT stays at zero. Are you sure that Torque is monitoring it correctly?

Also for your post-cat o2 sensor, it sees no real difference with your pre-cat o2 sensor. Is your Cat converter OK? But you would think it would turn on the appropriate code if there was a problem. Should be a much slower cycle than the pre-cat O2 sensor (at >2000 rpm) if converter is OK

Last edited by LesMyer; 01-17-2018 at 11:29 AM.