Fuel injector circuit problem - 2000 Blazer

#1

I am having a problem similar to several other posts whereby my Blazer began to stall when driving at highway speeds. This progressed to the point that it would not start at all. I suspected a failing CKP and proceeded to do all the Gen2 tests posted here and in Swarttllk's DIY listing. After running through the troubleshooting checklist and checking all the sensors and components; ignition coil, distributor cap, wires, plugs, compression, CKP, (all of which I replaced with new), I focused on the fuel injector circuit. I tested to see that I had 12V to the injectors (which I did) and hooked up a noid light across each of the sockets in the injector harness. I discovered that the noid light lit and stayed lit as soon as I turned the ignition to the "run" position. That being said, I did get a brighter "flash" when turning the engine over, confirming the presence of a signal from the CKP. Realizing that I must have a grounded wire between the injector harness and the VCM, I unplugged the Red connector at the VCM and the noid light went out so it eliminated the possibility of a ground between. Thinking I had a ground in the VCM, I installed and flashed a rebuilt VCM only to find that the ground persisted when the red connector was plugged into the VCM. . Is there anything else in the circuit that would cause the VCM's fuel injector drivers to remain continually closed?

I've spent way too much time and money on this problem!

I've spent way too much time and money on this problem!

#2

Whenever the crankshaft position sensor is moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed with a capable scan tool before the engine will run properly. (the el cheapo $500 jobbies won't do it )

)

Does the check engine light come on and go off during the bulb check?

Does, or did, the check engine light flash or remain on while driving?

Was there a DTC, (Diagnostic Trouble Code) in memory that the flow chart specifically instructed you to replace the crankshaft position sensor?

Are there any DTC's in memory?

If so, post them in the order they are/were retrieved.

Have you checked the fuel filter for restriction?

Have you checked fuel pressure and leakdown?

If so, what were the results?

What was the manufacturer of the parts that you replaced?

)

)Does the check engine light come on and go off during the bulb check?

Does, or did, the check engine light flash or remain on while driving?

Was there a DTC, (Diagnostic Trouble Code) in memory that the flow chart specifically instructed you to replace the crankshaft position sensor?

Are there any DTC's in memory?

If so, post them in the order they are/were retrieved.

Have you checked the fuel filter for restriction?

Have you checked fuel pressure and leakdown?

If so, what were the results?

What was the manufacturer of the parts that you replaced?

Last edited by Captain Hook; 01-04-2013 at 08:26 PM.

#3

Thank you for the quick reply Captain Hook. To answer your questions:

* There have never been any DTC's set

* 60psi fuel pressure with no leak down and constant pressure while running

* CKP was changed because I replaced the engine front cover after removing original to check to see if the timing chain had jumped a tooth (it didn't).

* Passlock seems to be ok (no security light)

The progression of my problem is as follows:

* Truck would operate correctly but began cutting out at unpredictable times ... would start but only chug on a couple of cylinders and die when accelerator was pressed ... after several start attempts, truck would run fine for awhile.

* Problem progressed to the point that it would start but only idle and gave the impression of being flooded ... leakdown test was done but no decrease in fuel pressure in 10 minutes

* This is when I found that when checking the fuel injector sockets in the injector harness with the noid light, the light came on as soon as the ignition was turned to on. From what I'm reading, this should not happen and suggests a ground .... when I unplugged the red connector at the VCM, the noid light went out so the ground was thought to be in the VCM. Changed that out but still get a noid lighting on all harness sockets as soon as the red connector is plugged into VCM

I'm wondering if another input to the VCM could be triggering the injector drivers within the VCM, or am I barking up the wrong tree?

* There have never been any DTC's set

* 60psi fuel pressure with no leak down and constant pressure while running

* CKP was changed because I replaced the engine front cover after removing original to check to see if the timing chain had jumped a tooth (it didn't).

* Passlock seems to be ok (no security light)

The progression of my problem is as follows:

* Truck would operate correctly but began cutting out at unpredictable times ... would start but only chug on a couple of cylinders and die when accelerator was pressed ... after several start attempts, truck would run fine for awhile.

* Problem progressed to the point that it would start but only idle and gave the impression of being flooded ... leakdown test was done but no decrease in fuel pressure in 10 minutes

* This is when I found that when checking the fuel injector sockets in the injector harness with the noid light, the light came on as soon as the ignition was turned to on. From what I'm reading, this should not happen and suggests a ground .... when I unplugged the red connector at the VCM, the noid light went out so the ground was thought to be in the VCM. Changed that out but still get a noid lighting on all harness sockets as soon as the red connector is plugged into VCM

I'm wondering if another input to the VCM could be triggering the injector drivers within the VCM, or am I barking up the wrong tree?

#4

The first huge clue is no DTC's set in memory. This means the problem is caused by something not monitored by the OBDII system. It also tells us the PCM, the sensors, injectors and associated wiring are also ok. You already know the injectors are not leaking as this would have shown up on the leakdown test. BTW, noid lights should NOT be used on this engine as it can damage the injector drivers in the PCM.

The fuel delivery system, (fuel pump & regulated fuel pressure) is not monitored by OBDII on this engine so the PCM can not set a DTC in memory if there is a failure.

"* Truck would operate correctly but began cutting out at unpredictable times ... would start but only chug on a couple of cylinders and die when accelerator was pressed ... after several start attempts, truck would run fine for awhile.

* Problem progressed to the point that it would start but only idle.."

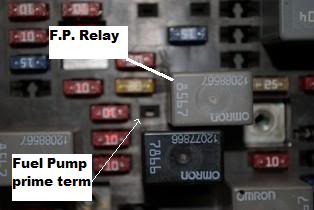

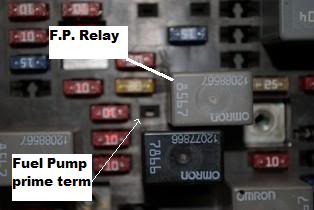

This is a classic example of low fuel pressure, and or low fuel volume to the injectors. Your reading of 60psi is at the low end of the allowable spec which could also mean that fuel volume is also at the low end. GM does not publish any "engine running" fuel pressure specs for this system, all readings are taken with the engine off. On your 2000, check fuel pressure and leakdown using this method: Make sure the fuel filter is not restricted. With the ignition OFF: Connect a fuel pressure tester to the service port near the distributor. In the underhood fuse panel there is a vacant terminal that is used to activate the fuel pump. Connect a fused 10 amp jumper wire to battery positive. Connect the other end to the fuel pump prime terminal:

Fuel pressure should indicate 60psi to 66psi while the pump is activated. Activate the pump several times while watching the needle on the presure tester. The needle must show immediate deflection and the pump must pressurize the system immediately each time you activate the pump. Next step is remove the jumper wire: pressure must remain above 55psi for at least 10 minutes after the pump shuts off. Note: when the pump is deactivated, pressure will drop slightly and hold. Post your results.

Just an FYI:

Timing chains are not an issue on this engine, and slack can be checked without any disassembly of the engine

Whenever the timing cover and or crankshaft position sensor are moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed with a capable scan tool. If it's not performed, the engine will run, but ignition timing, injector timing, injector pulse width, etc will not be correct.

The fuel delivery system, (fuel pump & regulated fuel pressure) is not monitored by OBDII on this engine so the PCM can not set a DTC in memory if there is a failure.

"* Truck would operate correctly but began cutting out at unpredictable times ... would start but only chug on a couple of cylinders and die when accelerator was pressed ... after several start attempts, truck would run fine for awhile.

* Problem progressed to the point that it would start but only idle.."

This is a classic example of low fuel pressure, and or low fuel volume to the injectors. Your reading of 60psi is at the low end of the allowable spec which could also mean that fuel volume is also at the low end. GM does not publish any "engine running" fuel pressure specs for this system, all readings are taken with the engine off. On your 2000, check fuel pressure and leakdown using this method: Make sure the fuel filter is not restricted. With the ignition OFF: Connect a fuel pressure tester to the service port near the distributor. In the underhood fuse panel there is a vacant terminal that is used to activate the fuel pump. Connect a fused 10 amp jumper wire to battery positive. Connect the other end to the fuel pump prime terminal:

Fuel pressure should indicate 60psi to 66psi while the pump is activated. Activate the pump several times while watching the needle on the presure tester. The needle must show immediate deflection and the pump must pressurize the system immediately each time you activate the pump. Next step is remove the jumper wire: pressure must remain above 55psi for at least 10 minutes after the pump shuts off. Note: when the pump is deactivated, pressure will drop slightly and hold. Post your results.

Just an FYI:

Timing chains are not an issue on this engine, and slack can be checked without any disassembly of the engine

Whenever the timing cover and or crankshaft position sensor are moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed with a capable scan tool. If it's not performed, the engine will run, but ignition timing, injector timing, injector pulse width, etc will not be correct.

Thread

Thread Starter

Forum

Replies

Last Post

aerovette99

2nd Generation S-series (1995-2005) Tech

46

09-28-2015 10:04 AM

Firebird14

2nd Generation S-series (1995-2005) Tech

18

02-23-2012 11:01 PM

dragem

2nd Generation S-series (1995-2005) Tech

0

06-26-2011 08:45 PM