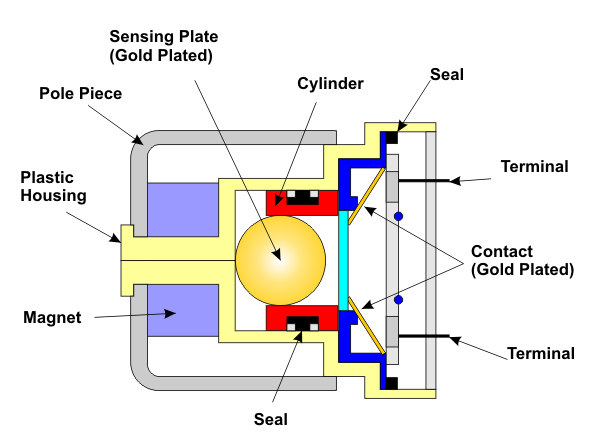

Inside an airbag sensor

#11

Great! Good job Christine! I truly love Your engineering attitude  I haven't been browsing the forum last days, as I went for a short vacation blazer trip and what a surprise on my comeback!

I haven't been browsing the forum last days, as I went for a short vacation blazer trip and what a surprise on my comeback!

So much of walking around a simple push button switch. I'll fix it myself. Just a bit of the soldering flux and epoxy. I remember well, there was a topic on rivets somewhere... Or maybe I'll try to fix it at spot? Anywy, You have just saved me $200 bucks.

Just a bit of the soldering flux and epoxy. I remember well, there was a topic on rivets somewhere... Or maybe I'll try to fix it at spot? Anywy, You have just saved me $200 bucks.

EDIT:

A digression from my side here.

In 2006 the EU council decided to apply the RoHS directive. The directive was supposed to "save the environment" and in my opinion became the most idiotic and grotesque act of a last decade. Under the pretext of fight for environmental cleanliness, the use of lead in the soldering process was forbidden. The truth, that the vast of lead contamination come with a lead-acid batteries or the shotgun pellets was completely ignored. The electronic industry had to switch from SnPb alloy to something else, because the official demands it. [1] The alloy switching process was done rapidly, and an alloy of SnAgCu was proposed instead.

Thing is, that joints soldered with a SnPb alloy were elastic and proven to be much more reliable. They had a possibility of adopting the material tensions that are related to the material heat expansion, deformation in time and so on. SnAgCu aren't. Under the tension they simply crack (that's where BGA reballing term comes in). Does it sound like an explanation why the electronic equipment was found much more reliable before 2006..? Do we "save the environment" producing tons of electronic waste that applies to the RoHS directive instead of keeping up a proven SnPb technology...? By looking the exclusions, I'd even swear they were pretty aware of what's gonna be and they wanted to cut the product lifetime to keep up the economy going.

Let's cut to the point. If anybody wants to repair the sensor, I highly recommend SnPb alloy. That would make the sensor last longer. I suppose, the joints there could be lead-free and thus we're forced to spend extra money for a new sensors.

[1] There are exclusions however, for example: a medical or sea vessels equipment.

I haven't been browsing the forum last days, as I went for a short vacation blazer trip and what a surprise on my comeback!

I haven't been browsing the forum last days, as I went for a short vacation blazer trip and what a surprise on my comeback!So much of walking around a simple push button switch. I'll fix it myself.

Just a bit of the soldering flux and epoxy. I remember well, there was a topic on rivets somewhere... Or maybe I'll try to fix it at spot? Anywy, You have just saved me $200 bucks.

Just a bit of the soldering flux and epoxy. I remember well, there was a topic on rivets somewhere... Or maybe I'll try to fix it at spot? Anywy, You have just saved me $200 bucks.EDIT:

A digression from my side here.

In 2006 the EU council decided to apply the RoHS directive. The directive was supposed to "save the environment" and in my opinion became the most idiotic and grotesque act of a last decade. Under the pretext of fight for environmental cleanliness, the use of lead in the soldering process was forbidden. The truth, that the vast of lead contamination come with a lead-acid batteries or the shotgun pellets was completely ignored. The electronic industry had to switch from SnPb alloy to something else, because the official demands it. [1] The alloy switching process was done rapidly, and an alloy of SnAgCu was proposed instead.

Thing is, that joints soldered with a SnPb alloy were elastic and proven to be much more reliable. They had a possibility of adopting the material tensions that are related to the material heat expansion, deformation in time and so on. SnAgCu aren't. Under the tension they simply crack (that's where BGA reballing term comes in). Does it sound like an explanation why the electronic equipment was found much more reliable before 2006..? Do we "save the environment" producing tons of electronic waste that applies to the RoHS directive instead of keeping up a proven SnPb technology...? By looking the exclusions, I'd even swear they were pretty aware of what's gonna be and they wanted to cut the product lifetime to keep up the economy going.

Let's cut to the point. If anybody wants to repair the sensor, I highly recommend SnPb alloy. That would make the sensor last longer. I suppose, the joints there could be lead-free and thus we're forced to spend extra money for a new sensors.

[1] There are exclusions however, for example: a medical or sea vessels equipment.

Last edited by Mike.308; 08-16-2018 at 03:05 AM.

#12

A good RH sensor should have around 1kOhm in between terminals.

LH one should have:

- zero resistance in between two pairs: A+B and C+D

- infinitive resistance in between any of {A,B} and {C,D}

-

#13

#14

#15

Great! Good job Christine! I truly love Your engineering attitude  I haven't been browsing the forum last days, as I went for a short vacation blazer trip and what a surprise on my comeback!

I haven't been browsing the forum last days, as I went for a short vacation blazer trip and what a surprise on my comeback!

So much of walking around a simple push button switch. I'll fix it myself. Just a bit of the soldering flux and epoxy. I remember well, there was a topic on rivets somewhere... Or maybe I'll try to fix it at spot? Anywy, You have just saved me $200 bucks.

Just a bit of the soldering flux and epoxy. I remember well, there was a topic on rivets somewhere... Or maybe I'll try to fix it at spot? Anywy, You have just saved me $200 bucks.

...

I haven't been browsing the forum last days, as I went for a short vacation blazer trip and what a surprise on my comeback!

I haven't been browsing the forum last days, as I went for a short vacation blazer trip and what a surprise on my comeback!So much of walking around a simple push button switch. I'll fix it myself.

Just a bit of the soldering flux and epoxy. I remember well, there was a topic on rivets somewhere... Or maybe I'll try to fix it at spot? Anywy, You have just saved me $200 bucks.

Just a bit of the soldering flux and epoxy. I remember well, there was a topic on rivets somewhere... Or maybe I'll try to fix it at spot? Anywy, You have just saved me $200 bucks....

You are very welcome. I hope you are able to fix this yourself. I was able to dig out about 1/2 to 2/3 of the rubbery-filler but to get the rest so to free the sensor enough to remove it from its package might be difficult without damaging the sensor. Be sure to post you attempt to do this repair.

As for the type so solder, yes, the lead-based solders have an advantage when the circuit is in an environment that vibrates. I also share you frustration with rules that create new problems.

BTW, that is a great circuit diagram synopsis you did. As I said, I suspect the failure in the sensors is not the sensing mechanism itself but rather the connections to the circuit boards attached to the sensors.

If anyone can fix one of these sensors at home, I'm sure it will be you.

#16

Once upon a time I've been interested in doing myself a heat-to-electric converters based on reversed Peltier's phenomenon.I've found a really nifty design that was held on vertical side of the stove with magnets. Once the hot surface of the generator was overheated, the generator was meant to fall off. Brilliant

Once upon a time I've been interested in doing myself a heat-to-electric converters based on reversed Peltier's phenomenon.I've found a really nifty design that was held on vertical side of the stove with magnets. Once the hot surface of the generator was overheated, the generator was meant to fall off. Brilliant  (While the furnace temperature usually does not go beyond ~400'C or ~750'F).

(While the furnace temperature usually does not go beyond ~400'C or ~750'F).

#17

Actually that would be the thing I might be worried about. I have my level of confidence with dealing electrics & electronics, and I would not mind driving a car with self-repaired airbag sensor. I am not sure about the potential copycats... Hoping a tag "do not attempt..." will do the job

Thread

Thread Starter

Forum

Replies

Last Post

spittybays

2nd Generation S-series (1995-2005) Tech

9

09-17-2012 02:52 PM

jdpilot

2nd Generation S-series (1995-2005) Tech

5

01-29-2008 07:20 PM

MeidleinA

2nd Generation S-series (1995-2005) Tech

7

12-19-2005 10:05 PM