No start replaced crank sensor and still no start!!!

#1

This is my first post. I have a 2dr 2000 gmc jimmy. When i bought it 5 months ago i put a camshaft sensor in it. Then last week i had a distributor put into it. And this past tuesday i went out to start it and no start. it would crank and want to start. but nothing.the fuel pump is working can hear it kick on. so i changed the crank sensor yesterday took my positive battery terminal off so it could reset the code to the crank sensor waited 20 min and screwed the terminal back on...got back in truck and tried to start it...but nothing...it just cranked and cranked!!!! PLEASE HELP VERY DESPERATE!!!

#4

Even though you can hear your fuel pump, it does not mean you have the proper pressures. The experts (I'm not one of them) on this forum all recommend beginning with a fuel leakdown test. It has solved many user's from tearing their hair out or wasting money on wrong fixes.

Key ON, engine OFF: within the two seconds that the pump is running when the key is turned on, the pressure should read between 60-66 psi.

Key OFF: the pressure must stay above 55 psi for at least 10 minutes.

You can borrow a fuel pressure gauge from many auto parts store. After the test, post your results and that will give the experts more info to begin helping you out.

Key ON, engine OFF: within the two seconds that the pump is running when the key is turned on, the pressure should read between 60-66 psi.

Key OFF: the pressure must stay above 55 psi for at least 10 minutes.

You can borrow a fuel pressure gauge from many auto parts store. After the test, post your results and that will give the experts more info to begin helping you out.

#5

^ X2, check fuel pressure and leakdown first.

Also, when the crankshaft position sensor or timing cover are moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn MUST be performed. If it's not done, the PCM will use the data from the last crankshaft position sensor relearn, which is now incorrect data. The engine should still start and run, but the ignition timing, injector timing, cylinder misfire identification etc etc will not be accurate. The relearn must be done with a capable scan tool, the el cheapo $500 scan tools that the auto parts stores have can not access the procedure.

Also, when the crankshaft position sensor or timing cover are moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn MUST be performed. If it's not done, the PCM will use the data from the last crankshaft position sensor relearn, which is now incorrect data. The engine should still start and run, but the ignition timing, injector timing, cylinder misfire identification etc etc will not be accurate. The relearn must be done with a capable scan tool, the el cheapo $500 scan tools that the auto parts stores have can not access the procedure.

#6

thanks!! i just put the new distributor cap on all the plugs are on right and still just cranking and cranking...ill have to check on the fuel presser tho. thanks for the tid bit of advice...

when i bought the crank shaft sensor it didnt come with spacers. would it still work without the spacers? it was from autozone.. my brother in law works at advance auto and he showed me one of his and it did come with spacers.

when i bought the crank shaft sensor it didnt come with spacers. would it still work without the spacers? it was from autozone.. my brother in law works at advance auto and he showed me one of his and it did come with spacers.

#7

I hope you installed an AC Delco cap & rotor, aftermarket ones are a waste of money, and yes, it does make a difference. Make sure you put silicone dielectric grease on all terminals of the cap.

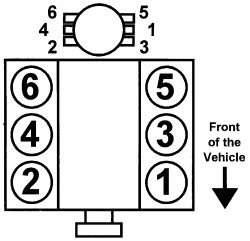

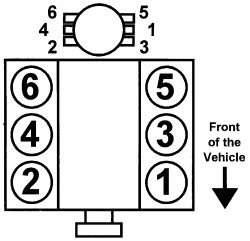

Look closely at the placement of the wires in the cap, make sure they are correct:

Make sure you have a blue, not orange, spark at each plug wire while cranking. Check the fuel pressure and leakdown and post your results.

The crank sensor is very sensitive, (that's why the relearn needs to be done) the sensor must be in the correct position, not too far in or out. If it's too far in, the tone ring on the crankshaft will contact the sensor and destroy it. If it's too far out, it will not generate a signal for the PCM to read. Unless you had a DTC specifically targeting the crank sensor, and the diagnostic flow chart instructed you to replace the sensor, the old sensor is OK and had the proper air gap.

Look closely at the placement of the wires in the cap, make sure they are correct:

Make sure you have a blue, not orange, spark at each plug wire while cranking. Check the fuel pressure and leakdown and post your results.

The crank sensor is very sensitive, (that's why the relearn needs to be done) the sensor must be in the correct position, not too far in or out. If it's too far in, the tone ring on the crankshaft will contact the sensor and destroy it. If it's too far out, it will not generate a signal for the PCM to read. Unless you had a DTC specifically targeting the crank sensor, and the diagnostic flow chart instructed you to replace the sensor, the old sensor is OK and had the proper air gap.

Thread

Thread Starter

Forum

Replies

Last Post

drewblaze99

Engine & Transmission

2

05-09-2015 02:56 PM

jjohnson77

2nd Generation S-series (1995-2005) Tech

8

10-13-2010 08:04 PM

ussexplorer

Paint, Body, & Interior

0

04-16-2010 04:49 PM

GM hater

2nd Generation S-series (1995-2005) Tech

7

01-09-2010 02:32 PM