P0300...no solution

#11

I juat had the P0300 also. Mine is a 01 with only 104k and here is what we found. Rough idle but seemed to clear up at above 1500 rpm. Checked about everything and did compression check and found the problem . Head gasket blown between 2 cylinders on the left bank. Didn't seem to get any water in the motor after replacing the freeze plugs and no bubbles in the burp tank so now I am replacing the head after we found it had a small crack at the exhaust valve. Just bought it and PO said the block was cracked due to not enough anti-freeze but it was just the freeze plugs. Have no idea if the cold cracked the head or not because I don't know how it ran before. Must have had some problem because the mechanic is the one who let it out with no anti freeze. Might check your compression and eliminate one source if it checks out. This code can be caused by many things so it's going through the list.

We are fortunate to have the Captain on here. He has helped me a few times already and his knowledge of these trucks is invaluable. Thanks again for the help.

We are fortunate to have the Captain on here. He has helped me a few times already and his knowledge of these trucks is invaluable. Thanks again for the help.

Last edited by specialty8; 02-06-2014 at 03:11 AM. Reason: spelling

#12

As I'm sitting here, I'm kinda curious to see what you guys have to say about my distributor. How much play is allowed when turning it side to side? I remember awhile back, I replaced the cap and rotor to attempt fixing the P0300. When i turned the rotor, it would move counter clockwise a good 1/16th of an inch. As you turn it that little bit, it felt like it was coming upwards toward you, I can imagine just like a bolt unscrews, because of the gear. Is there supposed to be ANY play?

#13

You're right about the way the gears are cut. When the engine is running, the shaft is pulled down. Axial play, (up and down) is acceptable up to ~ 1/8". Normal for the shaft to turn slightly, and raise up, while turning by hand. Radial play, (side to side, not rotating) is not acceptable.

Last edited by Captain Hook; 02-11-2014 at 09:57 PM.

#14

Roger that. I noticed also, awhile back, that there was some coolant seeped along the top where the LIM meets the heads. both sides. I suppose that could either mean A:the head gaskets are blown or B: LIM gaskets shot. Coolant disappearing from rad/overflow, but not overheating and I haven't filled it up....could either of those be an indication that this misfire is occuring because coolant is leaking into the combustion chamber, but only when above a certain temperature outside? Sorry for all the questions, I'd rather fix it myself than take it to the mechanic to have it fixed/misdiagnosed.

#15

Pull the plugs and do a compression test. Also if you have a bad head gasket or cracked head you should have a wet plug or so. If the recovery tank is bubbling it is compression pushing back into the coolant . Do you have excessive steam coming out of the exhaust? Also changing head gaskets is quite a job and you need some good mechanical skills. And a good assortment of tools a a torque wrench for head bolts and manifold bolts. Good luck.

#16

.....I noticed also, awhile back, that there was some coolant seeped along the top where the LIM meets the heads. both sides.... Coolant disappearing from rad/overflow, but not overheating and I haven't filled it up....could either of those be an indication that this misfire is occuring because coolant is leaking into the combustion chamber, but only when above a certain temperature outside?

Lower intake manifold gaskets are leaking, probably not a head gasket. It's extremely rare for an intake gasket failure to suck coolant into a combustion chamber due to the distance between the coolant ports and the intake ports. If the coolant is neglected, electrolysis and corrosion will eat away at the manifold and head around the coolant ports. Using ethylene glycol accelerates the process as it does not protect against electrolysis like Dexcool does. Eventually the gasket can no longer seal properly and the cooling system pressure pushes the coolant out. Felpro #MS98002T gasket set will not leak, if you clean the surfaces properly and follow the tightening sequence and torque specs.

Replacing the gaskets is not difficult, but it is time consuming. If you haven't done one before, plan on the better part of a day. It requires an accurate inch pound torque wrench, but no other "special" tools. There are several how-to's here on the forum.

#17

UPDATE: here are the readings I pulled today, as the weather is 37 degrees and the truck was misfiring like crazy so the P0300 popped up again.

DTCFRZF: P0300

FUELSYS1: CL

FUELSYS2: CL

LOAD_PCT (%): 22.4

ETC (F): 192F

SHRTFT1: +9.4

LONGFT1: +25.0

SHRTFT2: +0.0

LONGFT2: +20.3

MAP (inHg): 17.7

RPM (/min): 2171

VSS (mph): 68

MAF (lb/min): 5.037

TP (%): 16.5

any ideas? Captain, I know you'll come up with something!

DTCFRZF: P0300

FUELSYS1: CL

FUELSYS2: CL

LOAD_PCT (%): 22.4

ETC (F): 192F

SHRTFT1: +9.4

LONGFT1: +25.0

SHRTFT2: +0.0

LONGFT2: +20.3

MAP (inHg): 17.7

RPM (/min): 2171

VSS (mph): 68

MAF (lb/min): 5.037

TP (%): 16.5

any ideas? Captain, I know you'll come up with something!

Last edited by RandyRhoadsFan82; 02-18-2014 at 08:16 PM.

#20

Positive fuel trims indicate a lean misfire, (PCM is trying to add fuel to satisfy the O2 sensors). It's caused by not enough fuel or too much air. This lets out leaky injectors, leaky regulator, and the entire secondary ignition system as possibilities. A failure in any one of them would cause a rich mixture, and negative fuel trims. The fact that LTFT on both banks were reading about the same, at the same time, the odds are it's not multiple injectors being plugged up simultaneously, intermittently, the same on each bank. Pretty much same scenario with a vacuum leak, to both banks, at the same time??? Ain't likely to happen intermittently. Low fuel pressure, or fuel starvation will cause a lean misfire. In post #4 your fuel pressure was 61psi, which is low, but within spec. That alone will not cause a lean misfire, but if fuel volume is low, or leakdown is excessive, that could easily cause it. Make sure the fuel filter is not restricted.

Here's how to check it:

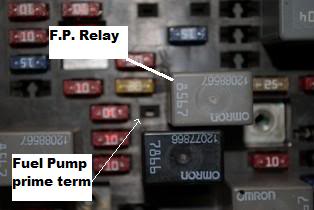

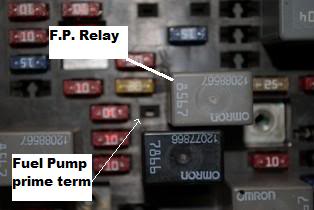

On 1998 through 2005, in the underhood fuse panel, there's a vacant terminal next to the fuel pump relay. It is referred to as the "fuel pump prime terminal", and it's used for activating the fuel pump during diagnostics. The circuit goes directly to the fuel pump motor.

Connect the fuel pressure tester to the test port next to the distributor.

Attach one end of a 14ga fused, (20amp) jumper wire to battery positive.

Connect the other end of the jumper to the pump prime terminal.

When the fuel pressure stabilizes, write it down.

Disconnect the jumper wire.

Wait 10 minutes and write down the pressure reading.

Post the readings.

Try momentarily touching the jumper to the pump prime terminal, (several times) while watching the needle on the tester. The needle must move up immediately, each time you activate the pump.

Here's how to check it:

On 1998 through 2005, in the underhood fuse panel, there's a vacant terminal next to the fuel pump relay. It is referred to as the "fuel pump prime terminal", and it's used for activating the fuel pump during diagnostics. The circuit goes directly to the fuel pump motor.

Connect the fuel pressure tester to the test port next to the distributor.

Attach one end of a 14ga fused, (20amp) jumper wire to battery positive.

Connect the other end of the jumper to the pump prime terminal.

When the fuel pressure stabilizes, write it down.

Disconnect the jumper wire.

Wait 10 minutes and write down the pressure reading.

Post the readings.

Try momentarily touching the jumper to the pump prime terminal, (several times) while watching the needle on the tester. The needle must move up immediately, each time you activate the pump.

Last edited by Captain Hook; 02-18-2014 at 08:47 PM.