Replacing lifters

#1

It's been awhile since my latest update on my low compression / engine misfire issue so I thought I'd update and ask for some advice.

As some of you know, back in the fall I was able to nail down my cylinder #6 misfire to low compression on that cylinder. After taking the valve cover off and checking out a few things (i.e., push rods, seals, etc.) the guy who was helping me out discovered a very small leak on the intake stroke. The valve was not closing completely.

We cleaned the combustion chamber and valves as best as we could through the spark plug provision and put it all back together. But before putting the valve cover back on we noticed how difficult it was for us to push the intake push rod down into the oil galley. "A bad lifter" is what we thought.

So, I've decided to tear back into the engine to replace the lifters for that cylinder. My question is this, do I need any special tools to remove the lifters? Also, is there a why to clean the lifters while it's still in the engine? I mean, could I try and run some solvent through the oiling system to maybe free up and clean out the lifters in question? I've heard of using a quart of ATF with an oil change to free up sticky lifters.

Thoughts?

As some of you know, back in the fall I was able to nail down my cylinder #6 misfire to low compression on that cylinder. After taking the valve cover off and checking out a few things (i.e., push rods, seals, etc.) the guy who was helping me out discovered a very small leak on the intake stroke. The valve was not closing completely.

We cleaned the combustion chamber and valves as best as we could through the spark plug provision and put it all back together. But before putting the valve cover back on we noticed how difficult it was for us to push the intake push rod down into the oil galley. "A bad lifter" is what we thought.

So, I've decided to tear back into the engine to replace the lifters for that cylinder. My question is this, do I need any special tools to remove the lifters? Also, is there a why to clean the lifters while it's still in the engine? I mean, could I try and run some solvent through the oiling system to maybe free up and clean out the lifters in question? I've heard of using a quart of ATF with an oil change to free up sticky lifters.

Thoughts?

#2

The lifters should slide right out... unless the engine has been neglected in the oil change department  If necessary, there's a tool for removing stuck lifters. It grips the upper part of the lifter and a built in slide hammer frees it up and pulls it out. Performance Tool Hydraulic Lifter Removal Tools - SummitRacing.com

If necessary, there's a tool for removing stuck lifters. It grips the upper part of the lifter and a built in slide hammer frees it up and pulls it out. Performance Tool Hydraulic Lifter Removal Tools - SummitRacing.com

You have two options:

1) Take the lifters in question out and apart, one at a time. Clean, inspect, reassemble and reinstall them, hope for the best.

2) Replace the lifters.

If necessary, there's a tool for removing stuck lifters. It grips the upper part of the lifter and a built in slide hammer frees it up and pulls it out. Performance Tool Hydraulic Lifter Removal Tools - SummitRacing.com

If necessary, there's a tool for removing stuck lifters. It grips the upper part of the lifter and a built in slide hammer frees it up and pulls it out. Performance Tool Hydraulic Lifter Removal Tools - SummitRacing.comYou have two options:

1) Take the lifters in question out and apart, one at a time. Clean, inspect, reassemble and reinstall them, hope for the best.

2) Replace the lifters.

#5

Never mind my last post. I didn't see the small bolts holding in the retainers.

Well, I ended up replacing all the lifters for cylinders 2, 4, and 6. Man, talk about a long job!

Anyway, after driving the truck around for a bit I'm still getting a rough idle and CEL came on while sitting at a traffic light. Same code, P0306, cylinder six misfire.

So, I guess it wasn't the lifters after all causing my low compression on that particular cylinder. Tomorrow, I plan on doing a compression test. I'm just to tired to do anymore.

Oh, I just thought of something. A few days ago I did a fuel pressure test at the intake manifold and it initially came up 60ish psi yet within a second or two it dropped, instantly to 55ish psi and held there for quit awhile. Shouldn't the pressure stay between 60 and 66 psi for awhile and slowly leak down no more than a few psi after 10 minutes or so.

I'm thinking I should do another fuel pressure test tomorrow and a compression test. Maybe I'll get some more answers after doing the to tests. The new fuel pump I installed a few months ago may not be working right? Maybe.

Well, I ended up replacing all the lifters for cylinders 2, 4, and 6. Man, talk about a long job!

Anyway, after driving the truck around for a bit I'm still getting a rough idle and CEL came on while sitting at a traffic light. Same code, P0306, cylinder six misfire.

So, I guess it wasn't the lifters after all causing my low compression on that particular cylinder. Tomorrow, I plan on doing a compression test. I'm just to tired to do anymore.

Oh, I just thought of something. A few days ago I did a fuel pressure test at the intake manifold and it initially came up 60ish psi yet within a second or two it dropped, instantly to 55ish psi and held there for quit awhile. Shouldn't the pressure stay between 60 and 66 psi for awhile and slowly leak down no more than a few psi after 10 minutes or so.

I'm thinking I should do another fuel pressure test tomorrow and a compression test. Maybe I'll get some more answers after doing the to tests. The new fuel pump I installed a few months ago may not be working right? Maybe.

#6

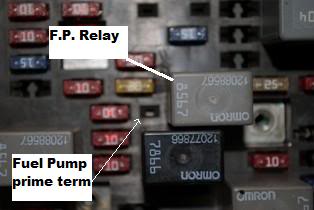

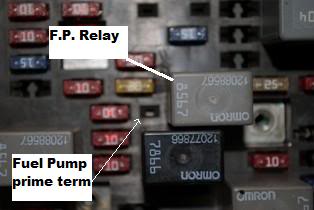

On your '98 there is a vacant terminal in the underhood fuse panel. It bypasses the fuel pump relay and goes directly to the fuel pump. It can be used for activating the fuel pump while checking fuel pressure:

Connect the fuel pressure tester to the service port near the distributor. Attach a fused 14ga jumper wire to battery positive. Hold the other end on the fuel pump prime terminal. Pressure must be 60psi to 66psi while the pump is activated. Remove the jumper wire and pressure will drop slightly, but must remain above 55psi for at least 10 minutes. If it fails either part of this test, there's a problem in the fuel delivery system and further testing is necessary to locate the problem.

Connect the fuel pressure tester to the service port near the distributor. Attach a fused 14ga jumper wire to battery positive. Hold the other end on the fuel pump prime terminal. Pressure must be 60psi to 66psi while the pump is activated. Remove the jumper wire and pressure will drop slightly, but must remain above 55psi for at least 10 minutes. If it fails either part of this test, there's a problem in the fuel delivery system and further testing is necessary to locate the problem.

#7

As soon as I saw your response, Captain, I decided 15 more minutes under the hood wouldn't hurt.

So, I did as you instructed and found nothing. With the pump priming I was seeing consistent 60 PSI and after removing the wire the pressure held at 55 PSI for more than 10 minutes. This is good news I was starting to get a little depressed thinking the new fuel pump went out on me already. Now, on to a compression test. What's 15 more minutes?

So, I did as you instructed and found nothing. With the pump priming I was seeing consistent 60 PSI and after removing the wire the pressure held at 55 PSI for more than 10 minutes. This is good news I was starting to get a little depressed thinking the new fuel pump went out on me already. Now, on to a compression test. What's 15 more minutes?

#8

After seeing your post Captain I decide to spend a little more time on the truck this evening. What's 15 more minutes, right?

Well, after following your instructions I came up with 60 PSI while the pump was priming. And, as soon as I removed the wire, it dropped to 55 PSI and held for more than 10 minutes. So, it's not a fuel delivery issue - good. I was beginning to think my new pump had failed too soon.

I also did another compression test. Cylinders 2,4 & 6 yielded 122 PSI. That's a difference of 30ish PSI for 2 & 4 BEFORE the lifter swap. Cylinder 6 was 124 PSI. This is about 30 PSI higher than BEFORE the swap. Somethings not right. The other cylinders came up with somewhere between 150 - 155 PSI ( 1, 3 & 5).

What would cause a decrease in pressure after swapping out lifters? I torqued the rocker stud nuts down to 20 Ft. Lbs. Isn't this right for screw in studs?

Thoughts?

Well, after following your instructions I came up with 60 PSI while the pump was priming. And, as soon as I removed the wire, it dropped to 55 PSI and held for more than 10 minutes. So, it's not a fuel delivery issue - good. I was beginning to think my new pump had failed too soon.

I also did another compression test. Cylinders 2,4 & 6 yielded 122 PSI. That's a difference of 30ish PSI for 2 & 4 BEFORE the lifter swap. Cylinder 6 was 124 PSI. This is about 30 PSI higher than BEFORE the swap. Somethings not right. The other cylinders came up with somewhere between 150 - 155 PSI ( 1, 3 & 5).

What would cause a decrease in pressure after swapping out lifters? I torqued the rocker stud nuts down to 20 Ft. Lbs. Isn't this right for screw in studs?

Thoughts?

#9

60psi is bare minimum, which means fuel volume could also be at the minimum. At this point it could be the regulator is set low, or the pump is weak. Regulated pressure at the service port is the lower of the regulator setting or maximum pump output. Only way to tell what's going on is by doing a maximum output pressure test at the fuel filter. All pressure and flow must dead end at the tester. You'll need to do some "creative plumbing" to adapt the tester to do it. Pump running must be 73psi to 108psi and must remain above 55psi for at least 10 minutes.

Your compression tests, were they wet, dry, or did you do both?

Your compression tests, were they wet, dry, or did you do both?