can anyone help?

#1

i have a 2000 chevy blazer 4x4 LS with the 4.3L v6 vortec and i bought it for $220 and put a new fuel tank/pump, new distributor complete and had it re-timed everything was great then a dtc code po147 came up so my obd told me it is bank 1 sensor 3 heater circuit malfunction, then about a few weeks later after ive been trying everywhere to find out where this bad sensor is now i have 2 new dtc codes po171 and po174 bank 1 and 2 running lean. im scared this is going to ruin my engine and i have a 02 sensor ordered that is both down stream and up stream. im in search of anyone with any info that may help. this truck is near mint condition and the motor has 155,300 on it and once warmed up runs so smooth you can barely tell its running. im hoping that this 02 problem will fix the lean codes. if anyone has a diagram of where this sensor is i would greatly appreciate it, also if you have any other info as far as the lean codes id appreciate that too! thanks so much for taking the time to view this.

#2

#3

B1S3 is the sensor behind the catalytic converter. You can test the sensor heater circuit resistance. It should be 5 ohms across the heater; test the resistance between the purple & tan wires at the sensor, terminals A & B of the connector. If it tests out ok at the sensor, then you'll want to repeat the test at the PCM which is located on top of the passenger side inner fender. You will need to remove the blue connector (C1) and probe pin 22 (Purple with white stripe) and pin 26 (Tan wire with white stripe). If these both test out ok, then it is possible there is an intermittent wiring issue somewhere between the sensor and the PCM. If that is the case, then we can discuss further, but you likely will find that the resistance is not in spec at the sensor which will be corrected by replacing the sensor.

As far as the P0171 & P0174 codes, I would recommend you do a thorough inspection of the vacuum & intake system to make sure there are no leaks that could be allowing unmetered air into the engine. These codes are not related to a B1S3 code. Only the upstream sensors (B1S1 & B2S1) are responsible for engine fuel management. The downstream sensor is only used for catalyst monitoring.

If there are no vacuum leaks or disconnected hoses/fittings in the intake system, then I would move on to testing fuel pressure. Low fuel pressure could result in a lean condition. You could also go ahead and clean the MAF sensor as they are notorious for getting dirty, throwing off the incoming air measurement which can also result in a lean condition. The sensor bulbs in the MAF should be gray in color. If they're black, they need to be cleaned. Get a can of sensor safe cleaner or MAF specific cleaner and spray things down. If that doesn't do it completely, you can very carefully wipe the sensor bulbs with a q-tip saturated in the cleaner to get them clean.

As far as the P0171 & P0174 codes, I would recommend you do a thorough inspection of the vacuum & intake system to make sure there are no leaks that could be allowing unmetered air into the engine. These codes are not related to a B1S3 code. Only the upstream sensors (B1S1 & B2S1) are responsible for engine fuel management. The downstream sensor is only used for catalyst monitoring.

If there are no vacuum leaks or disconnected hoses/fittings in the intake system, then I would move on to testing fuel pressure. Low fuel pressure could result in a lean condition. You could also go ahead and clean the MAF sensor as they are notorious for getting dirty, throwing off the incoming air measurement which can also result in a lean condition. The sensor bulbs in the MAF should be gray in color. If they're black, they need to be cleaned. Get a can of sensor safe cleaner or MAF specific cleaner and spray things down. If that doesn't do it completely, you can very carefully wipe the sensor bulbs with a q-tip saturated in the cleaner to get them clean.

#4

ok i did put a brand new fuel pump in it with the new gas tank in aug 2018 im gonna change the sensor and i will check the vacum lines, ive looked under the hood and im pretty good with mechanics on the older (86-94) kind of trucks but not this newer stuff. i did see some vacum lines where would they plug into? should i change the b1s1 and b2s1 just in case? im really baffled at this but it all started with that heater circuit malfunction then this lean stuff it started at bank 1 then a few weeks later it was both running lean and the truck has no symptoms what so ever accept it lacks power until its warmed up and i am not sure but the ignition coil is pretty rusted around the edges and dont want to replace it until i figure out this lean thing because i dont want to have spark plug detonation. i have a multimeter an obd2 that ive tried to do the 02 sensor test and it says its not supported also ive never had an obd before and i have an option to do live stream data but i dont know how to even interpret what its telling me. im sorry to bother you guys with my beginner stuff but i really need help i am going to also check the MAS and how do i check MAP? thanks so much for responding to me i really appreciate it.

#5

I don’t believe an 02 sensor is the problem. You will need to look at why it’s running lean. First thing that comes to mind would be MAF,MAP, fuel pump, vacuum leak. If @LesMyer sees this I’m sure he will have the answers. Good luck!

Brad

Brad

As for live stream data - here's a plot of O2 sensors that are working correctly with the PCM to control the fuel mixture.

Last edited by LesMyer; 01-23-2019 at 07:50 AM.

#6

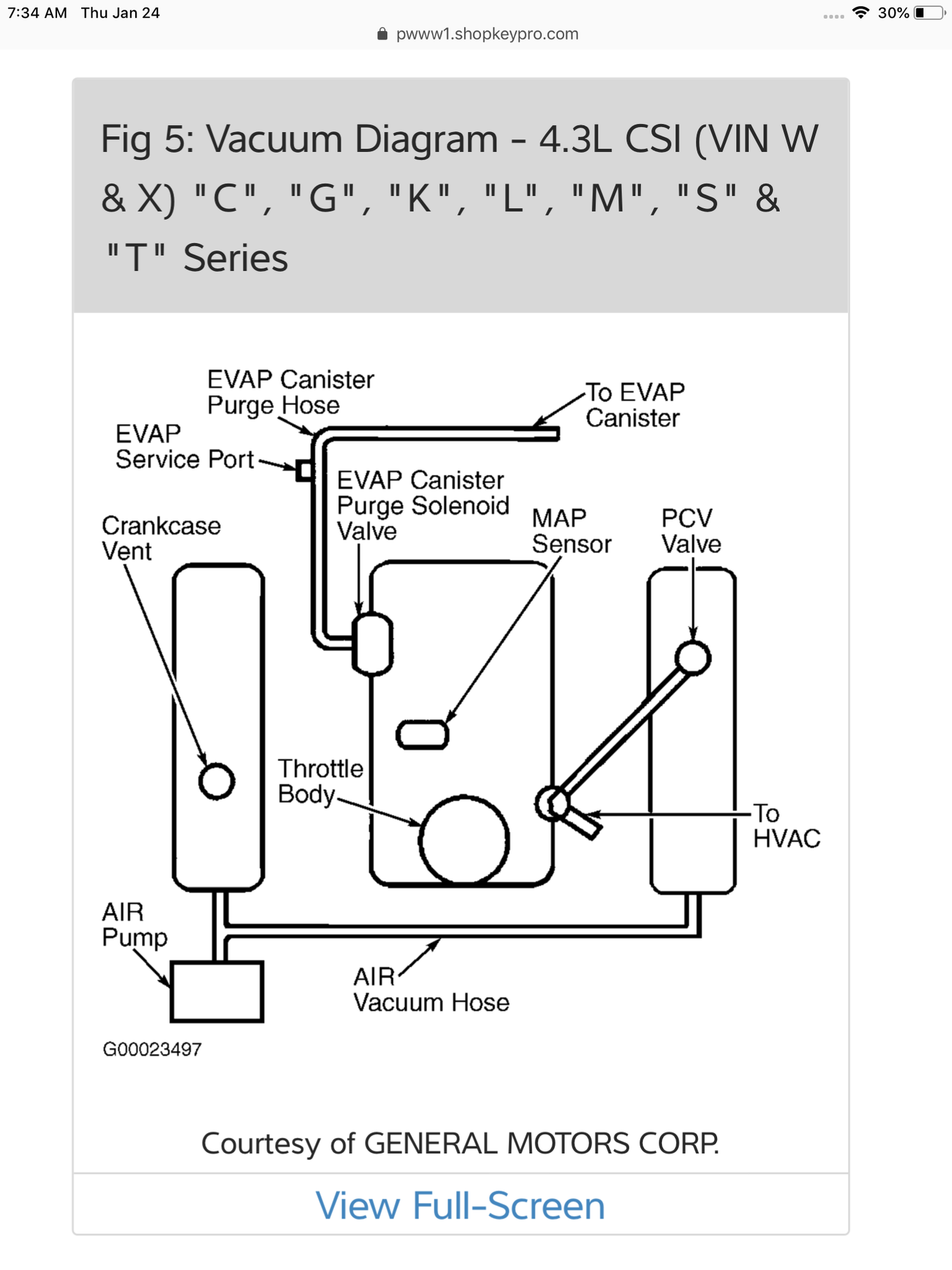

brad, i checked some vacum lines, and the oil fill is not seated all the way all the vacum lines are connected to the intake properly but one sticks out to me because its almost wrapped around the oil fill and streched all the way down to what i believe is the air pump. im gonna mess with that and also check the MAF and the MAP how would i check that and what is the number i should be looking for? les myer, im not determinded to change all 02 sensors i could care less about that, i am more concerned with both banks running lean. im going to do as recommended by brad, but as a first time i dont know what the correct fuel pressure number should be as well as the MAP. i really appreciate all this info its gonna take me a while im fighting cancer right now and the cold here isnt helping i am gonna give it hell to get the numbers back to you guys so we can further figure this out. thank you for taking the time to share your knowledge with me and i look forward to talking more to you guys. THANKS AGAIN, John

#7

We are here to help you fully diagnose the problem and get it corrected with the least amount of out of pocket expense provided you have some basic tools.

The assumption that you replaced the pump therefore you should have proper fuel pressure does not always prove to be correct which is why we recommend actual testing of the pressure. A fuel pressure test gauge can often be rented/borrowed from most auto parts stores for a small rental fee that you get back when you return it. Many, MANY people here have replaced the pump only to find that they still had this or that problem, replaced many other expensive parts on the engine, and came back to the conclusion that the fuel pressure was too low.

If it isn't raining, today might be the day to get out there and work on it. Highest temperatures in the forecast!

The assumption that you replaced the pump therefore you should have proper fuel pressure does not always prove to be correct which is why we recommend actual testing of the pressure. A fuel pressure test gauge can often be rented/borrowed from most auto parts stores for a small rental fee that you get back when you return it. Many, MANY people here have replaced the pump only to find that they still had this or that problem, replaced many other expensive parts on the engine, and came back to the conclusion that the fuel pressure was too low.

If it isn't raining, today might be the day to get out there and work on it. Highest temperatures in the forecast!

#8

brad, i checked some vacum lines, and the oil fill is not seated all the way all the vacum lines are connected to the intake properly but one sticks out to me because its almost wrapped around the oil fill and streched all the way down to what i believe is the air pump. im gonna mess with that and also check the MAF and the MAP how would i check that and what is the number i should be looking for? les myer, im not determinded to change all 02 sensors i could care less about that, i am more concerned with both banks running lean. im going to do as recommended by brad, but as a first time i dont know what the correct fuel pressure number should be as well as the MAP. i really appreciate all this info its gonna take me a while im fighting cancer right now and the cold here isnt helping i am gonna give it hell to get the numbers back to you guys so we can further figure this out. thank you for taking the time to share your knowledge with me and i look forward to talking more to you guys. THANKS AGAIN, John

MAF can be checked with the scanner. Should be around 5g/sec at idle. Should reach 100g/sec before trans shifts into second under full throttle. You can convert reading if necessary, depending on the units of your scanner.

MAP can be checked with the scanner. Should read barometric pressure at KOEO. You can convert reading if necessary, depending on the units of your scanner.

MAT can be checked with the scanner. Should read ambient temp before you start it.

ECT can be checked with the scanner. Should read ambient temp before you start engine and stabilize at thermostat temp.

When both banks go lean and set the codes, the PCM is simply telling you that it tried to richen the fuel mix (by raising fuel trim) over factory calibration to meet the A/F mix specification and could not get it there for whatever reason. You can look at fuel trim using the scanner. Note that fuel trim is a dynamic thing that is constantly changing and swinging back and forth - so better to plot fuel trim. Note that ±10 on the fuel trim is considered normal.

Last edited by LesMyer; 01-23-2019 at 01:17 PM.

#9

good morning guys, i did a check with my scanner the truck at idle before the rain to check the map and the original number i got was 9.75 inhg then 10.5 then 26.01 then 47.58 inhg it kept bouncing around. im not sure if this is normal or i may need to switch to my other sensor i did notice the part where i said about the oil fill not fully seated and the vac. line was really stretched come to think of it i did have a secondary air code but it went away im gonna unconnect that line and re-route it around the oil fill and see if that does anything and i did notice on a 3 way splitter there were a few vac. lines that were all cracked and looked dry rotted on the end of the 3 way. also my obd is telling me the bank 1 running lean is both a dtc and a pending dtc same with the po147? is this normal what does it mean? also when i do my koeo live data stream should i drive it around or leave it at idle? all my number for fuel trim air temp were giving numbers then flat lining then would give me a new number im just learning how to use the obd other then to diagnose. same thing with the MAP kept bouncing flat lining then a number would come up.

Last edited by jfin; 01-24-2019 at 05:08 AM.