(Fuel pressure issue) First post ever

#1

I have a 1998 chevy blazer with a 4.3 vortec. The truck is cranking longer than usual but once the truck is running it runs fine with NO hesitation, or backfires. The Blazer does have some power loss and maybe the slightest but almost unnoticeable rumble while idling, but I believe it's because of the fuel pressure. I replaced the Fuel Pressure Relay since it was cheap but nothing changed. I also replaced the Fuel Filter and nothing changed the performance. I did a fuel pressure test and my results were: priming the fuel pump with the truck on (not with the truck running) the fuel pressure gauge showed 61 psi. Once the fuel pump stopped priming for 2 seconds the pressure gauge dropped dramatically down to 5 psi then dropped to 0 psi in less than 1 min. Once I started the truck (the truck actually running) the pressure gauge showed the pressure holding steady at 52 psi. According to the Haynes manual the psi ranges are ok EXCEPT the psi dropping after priming the fuel pump. I am to believe its either the Fuel Pressure Regulator or the Check Valve on the fuel pump. I was just wanting some advice from someone else who knows the vehicle better than me before I have to take apart the engine to check the Fuel Pressure Regulator or buy a new Fuel Pump. Sorry for the long post I am trying to give the most detail I could.

#2

A word about the manual you are using: Half of the information is missing, the other half is incorrect, and proper test procedures are non-existant. When it comes to specs, don't believe a word. If you want to learn how to change the oil, it might be OK. Anything beyond that, it's worthless. the factory GM dealer issue shop manual is the only way to go. Available online new for ~$200, and used ones are cheaper on Ebay, if you can find them

GM does not publish any "engine running" fuel pressure specs for this engine, so if you see them somewhere, don't believe them Regulated fuel pressure and leakdown tests are all performed with the engine off.

Regulated fuel pressure and leakdown tests are all performed with the engine off.

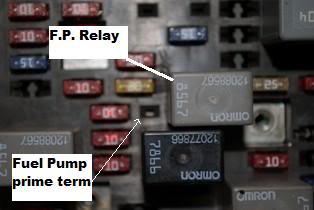

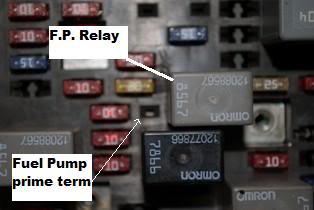

1998 and newer S&T series, there is a vacant terminal in the underhood fuse panel, right next to the fuel pump relay. It is the "pump prime" terminal and the circuit runs directly to the fuel pump.

1. Connect the fuel pressure tester to the service port next to the distributor.

2. Connect a fused jumper wire from battery positive to the pump prime terminal.

3. After the fuel pressure stabilizes on the tester, write it down.

4. Remove the jumper wire.

5. Wait 10 minutes and write down the fuel pressure.

6. Post your results.

If it fails one or both of the tests, there is a problem with fuel delivery. You will need to do some "creative plumbing" to the pressure tester so that it will connect directly to the fuel filter outlet. All pressure and fuel flow must end at the tester.

1. Install the jumper wire as you did in the previous test.

2. Write down the pressure.

3. Remove the jumper wire.

4. Wait 10 minutes and write down the pressure.

5. Post the results.

Depending on the results from all of these tests, it will tell where the problem is, and possibly what the problem is.

GM does not publish any "engine running" fuel pressure specs for this engine, so if you see them somewhere, don't believe them

Regulated fuel pressure and leakdown tests are all performed with the engine off.

Regulated fuel pressure and leakdown tests are all performed with the engine off.1998 and newer S&T series, there is a vacant terminal in the underhood fuse panel, right next to the fuel pump relay. It is the "pump prime" terminal and the circuit runs directly to the fuel pump.

1. Connect the fuel pressure tester to the service port next to the distributor.

2. Connect a fused jumper wire from battery positive to the pump prime terminal.

3. After the fuel pressure stabilizes on the tester, write it down.

4. Remove the jumper wire.

5. Wait 10 minutes and write down the fuel pressure.

6. Post your results.

If it fails one or both of the tests, there is a problem with fuel delivery. You will need to do some "creative plumbing" to the pressure tester so that it will connect directly to the fuel filter outlet. All pressure and fuel flow must end at the tester.

1. Install the jumper wire as you did in the previous test.

2. Write down the pressure.

3. Remove the jumper wire.

4. Wait 10 minutes and write down the pressure.

5. Post the results.

Depending on the results from all of these tests, it will tell where the problem is, and possibly what the problem is.

#3

In the search box, enter this exactly: fuel leakdown "captain hook"

You find some great threads that go deeper. Here is one https://blazerforum.com/forum/2nd-ge...d-75428/page3/ Look at post #22

You find some great threads that go deeper. Here is one https://blazerforum.com/forum/2nd-ge...d-75428/page3/ Look at post #22

#4

Thank you very much for the fast reply's. I will have to invest in a factory GM dealer issue shop manual here soon ;D I am in my computer application class right now and wont be home from school until later tonight, but I will see if I can grab a fused jumper wire from the nearest auto store or make one my self and do the testing you described Captain Hook =D I do have one dumb question, if I made my own fused jumper wire could I use an alligator clip with a wire connecting to a fuse then a wire coming from the fuse to connect to the fuel pump prime terminal? also you mentioned "Connect a fused jumper wire from battery positive to the pump prime terminal." do I also need to connect a wire to the battery negative or do I just connect battery positive to the terminal. I apologize for the noobish questions I'm a novice when it comes to vehicles haha. Thank you rockp2 for your reply also. I will check out those threads as soon as I can.

#5

You can make a jumper wire, (the fuse is for safety). Just have to go from battery positive to the pump prime terminal, no negative wire needed. The jumper wire needs to be 14 or 16 gauge. Yes you can put an alligator clip on one end, then stick the other end in the pump prime terminal. There are battery positive studs that you can connect to right on the under hood fuse panel. Jumper wire really only needs to be about 12" long.

#6

Ok thank you very much Captain Hook. I just made one but its to dark outside right now but if I have time tomorrow I will do the testing and post my results. Thanks again for your help. =D

Last edited by WIZZATCH; 01-19-2014 at 12:55 AM.

#7

OK Captain Hook, I followed the first 6 steps you listed and here are my results.

Step 3.) Once the fuel pressure stabilized after connecting the fused jumper wire, the pressure gauge showed the pressure stabilizing at 60 1/2 Psi

Step 5.) The fuel pressure dropped dramatically down to 10 Psi in less than 15 seconds. I waited the full 10 minutes and the pressure was stabilized at 4 Psi basically the whole time after the dramatic drop to 10 Psi.

I will now do the next 5 steps you listed and post them when ever I get time today or tomorrow. Busy watching the Broncos and then the 49ers play today

Just to verify so I wont do the testing wrong. You mentioned that I should connect "the pressure tester so that it will connect directly to the fuel filter outlet. All pressure and fuel flow must end at the tester." So once I disconnect the quick connect fuel line from the fuel filter outlet, I connect my pressure tester to the fuel filter and I keep the quick connect fuel line i disconnected unconnected, so then all pressure and fuel flow will end at the tester like you mentioned?

Step 3.) Once the fuel pressure stabilized after connecting the fused jumper wire, the pressure gauge showed the pressure stabilizing at 60 1/2 Psi

Step 5.) The fuel pressure dropped dramatically down to 10 Psi in less than 15 seconds. I waited the full 10 minutes and the pressure was stabilized at 4 Psi basically the whole time after the dramatic drop to 10 Psi.

I will now do the next 5 steps you listed and post them when ever I get time today or tomorrow. Busy watching the Broncos and then the 49ers play today

Just to verify so I wont do the testing wrong. You mentioned that I should connect "the pressure tester so that it will connect directly to the fuel filter outlet. All pressure and fuel flow must end at the tester." So once I disconnect the quick connect fuel line from the fuel filter outlet, I connect my pressure tester to the fuel filter and I keep the quick connect fuel line i disconnected unconnected, so then all pressure and fuel flow will end at the tester like you mentioned?

Last edited by WIZZATCH; 01-19-2014 at 03:25 PM.

#8

Your results on steps 3 & 5 tell us there is definitely a problem with fuel delivery. That's the big picture, now we need to narrow down which end of the vehicle has the problem. The results of the next test will tell us if the problem is in the tank, or in the plenum.

"So once I disconnect the quick connect fuel line from the fuel filter outlet, I connect my pressure tester to the fuel filter and I keep the quick connect fuel line i disconnected unconnected, so then all pressure and fuel flow will end at the tester like you mentioned?"

Yes, that is correct. This fitting will connect to the fuel filter outlet:

Dorman Products - 800-121 You can attach a piece of 3/8" fuel injection rated hose to it. Connect the other end to the pressure tester. Depending on what type of tester you have, you will need to get the 3/8" line to attach to your tester.

"So once I disconnect the quick connect fuel line from the fuel filter outlet, I connect my pressure tester to the fuel filter and I keep the quick connect fuel line i disconnected unconnected, so then all pressure and fuel flow will end at the tester like you mentioned?"

Yes, that is correct. This fitting will connect to the fuel filter outlet:

Dorman Products - 800-121 You can attach a piece of 3/8" fuel injection rated hose to it. Connect the other end to the pressure tester. Depending on what type of tester you have, you will need to get the 3/8" line to attach to your tester.

#9

I just finished with the last 5 steps you listed and my results are:

Step 2.) Once the fuel pressure stabilized after connecting the fused jumper wire, the pressure gauge showed the pressure stabilizing at 79 Psi.

Step 3.) The results came out to be the same as step 5 in the previous test. (The fuel pressure dropped dramatically down to 10 Psi in less than 15 seconds. I waited the full 10 minutes and the pressure was stabilized at 4 Psi basically the whole time after the dramatic drop to 10 Psi.)

Do the results of these tests show that the fuel pump is the issue? Possibly the check valve stuck open, allowing the fuel to drain back into the fuel tank?

Step 2.) Once the fuel pressure stabilized after connecting the fused jumper wire, the pressure gauge showed the pressure stabilizing at 79 Psi.

Step 3.) The results came out to be the same as step 5 in the previous test. (The fuel pressure dropped dramatically down to 10 Psi in less than 15 seconds. I waited the full 10 minutes and the pressure was stabilized at 4 Psi basically the whole time after the dramatic drop to 10 Psi.)

Do the results of these tests show that the fuel pump is the issue? Possibly the check valve stuck open, allowing the fuel to drain back into the fuel tank?