P1345 and P0300

#1

Alright ladies and gentlemen I picked up a 99 Jimmy the other day. V6 4wd and loaded. Lady thought it was a rod knocking however when I started it I knew right away to just hand over the cash and keep my mouth shut. The jimmy had quite a rough idle and the check light was on. She claims she parked at the gas station and came out and started it and it started running like it did. She didn't get gas if that helps. So I had the lights read at autozone and those two codes came up along with an evap code. Usually what cames up with a gas cap but I frogot the code number. I did some observing and records show it has all new spider injection and transmission. I googled for a bit and found people pointing to the distributor gear but I pulled the distributor and took it to autozone and compaired with a new one and it looked fine. Also had the same play and such as a new one so I ruled it out. I went ahead and reset the distributor even though I marked it and did everything right and it acted the same but seemed very slightly better. I wanted to ask for people's opinion before I dog some more. My next guesses are Cam or crank sensor or timing chain. It idles and misfires at idle but when you rev it up to higher rpms it will smooth out. I do not have a scanner to check timing retard unfortunitly. Just wanting some input before I dig more.

#2

You saved yourself some time, grief, and money by checking here first  If/when the crankshaft position sensor or timing cover, are moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed. It requires a scan tool capable of initiating the relearn, and the elcheapo $500 jobbies can't do it.

If/when the crankshaft position sensor or timing cover, are moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed. It requires a scan tool capable of initiating the relearn, and the elcheapo $500 jobbies can't do it.

Always diagnose & repair DTC's in the order they are retrieved. In your case, the P1345 means the distributor is not installed correctly. It's off at least one tooth in one direction or the other. Whenever the distributor hold down is loosened, camshaft retard must be checked and adjusted. Again, using a capable scan tool.

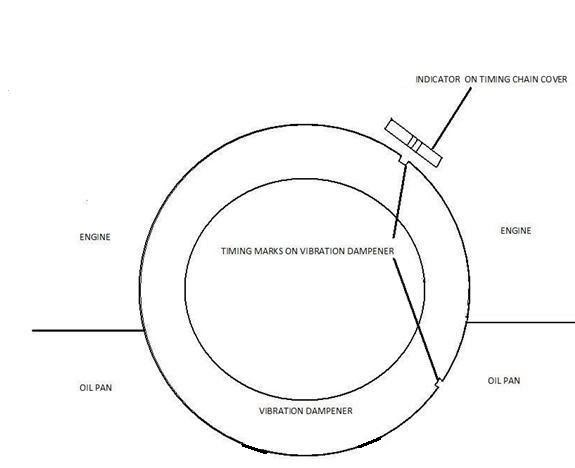

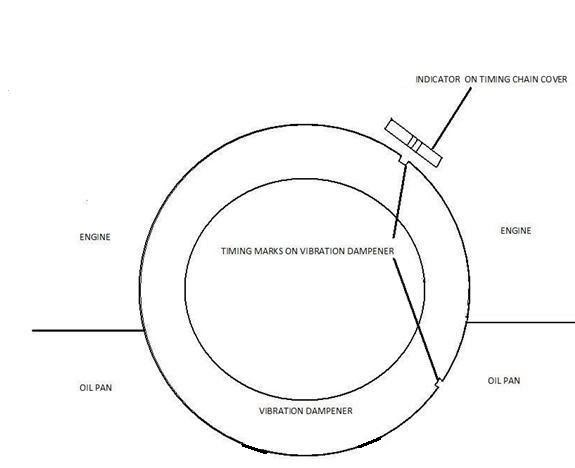

Here's how to eliminate the P1345: using a socket and ratchet on the crankshaft bolt, slowly rotate the crankshaft clockwise until the index marks line up exactly like this:

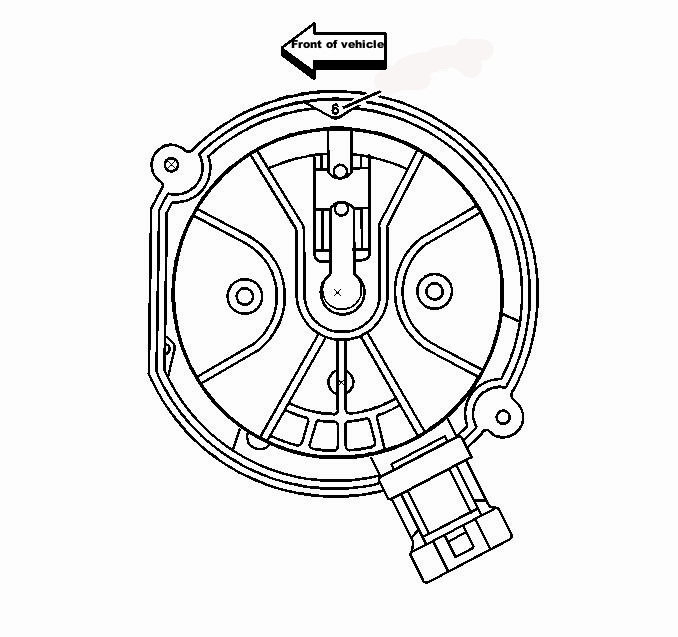

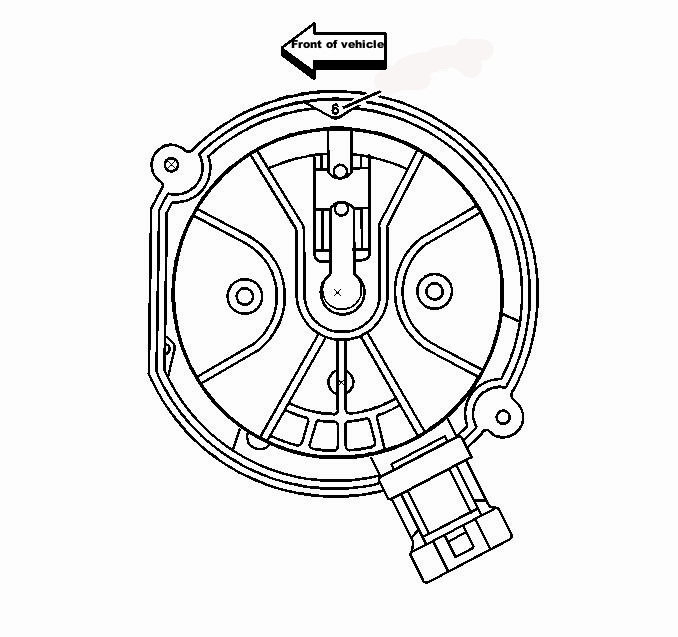

The distributor rotor will not be perfectly lined up with the "6", but it will be fairly close. It needs to be closer than what it is.

Make sure the crank marks are line up perfectly. If you pass the marks, DO NOT rotate the crankshaft counter clockwise. Rotate 2 revolutions clockwise and be a little more careful when it starts getting close. Remove the distributor, and reinstall it so the rotor points closer to the "6". You might need to move the oil pump driveshaft so the distributor will fully seat against the intake manifold.

This will eliminate the P1345, and quite possibly the P0300 as well.

If/when the crankshaft position sensor or timing cover, are moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed. It requires a scan tool capable of initiating the relearn, and the elcheapo $500 jobbies can't do it.

If/when the crankshaft position sensor or timing cover, are moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed. It requires a scan tool capable of initiating the relearn, and the elcheapo $500 jobbies can't do it.Always diagnose & repair DTC's in the order they are retrieved. In your case, the P1345 means the distributor is not installed correctly. It's off at least one tooth in one direction or the other. Whenever the distributor hold down is loosened, camshaft retard must be checked and adjusted. Again, using a capable scan tool.

Here's how to eliminate the P1345: using a socket and ratchet on the crankshaft bolt, slowly rotate the crankshaft clockwise until the index marks line up exactly like this:

The distributor rotor will not be perfectly lined up with the "6", but it will be fairly close. It needs to be closer than what it is.

Make sure the crank marks are line up perfectly. If you pass the marks, DO NOT rotate the crankshaft counter clockwise. Rotate 2 revolutions clockwise and be a little more careful when it starts getting close. Remove the distributor, and reinstall it so the rotor points closer to the "6". You might need to move the oil pump driveshaft so the distributor will fully seat against the intake manifold.

This will eliminate the P1345, and quite possibly the P0300 as well.

#3

When I installed the distributor I followed every step you listed. When I took it out I printed out instructions off of a website that had all the steps and followed them. First time I had done that and it actually ran slightly better so I was pretty proud of myself. Me and grandpa and his friend have been arguing about it a lot. So after hours of convincing them to take it out to Dave, who has all kinds of computers I guess. I didn't go because I would end up arguing with Dave about it. Well When grandpa got back I guess the guy said it read 22 codes. Then he told grandpa the torque converter bolts were probably loose which is why its running that way... oook.. However the crankshaft sensor came up on one of those codes. Soooo im going to give the cranksensor a shot and see if Dave can do a relearn. I do appriciate the reply captin hook and having the details on how to do it. I wish I had seen it because THAT is a lot easier to understand than the 10 page crap I was going off of haha.

#4

If you are getting a code for the crank sensor, and following the diagnostic flow chart specifically tells you to replace the sensor, fine, if not, the sensor is ok, don't mess with it. Consider yourself warned, if you mess with the crankshaft sensor, you need to do the relearn. If you have to take it to a shop, it's not cheap.

#5

Well a new crank sensor took away the missing out, however it still runs rough and shakes. All of a sudden it started rattling bad and that sound is what it had done before making the lady believe it was a rod. It wasn't as bad when we first brought it home because she only drove a mile and parked it and we trailered it. It turns out the noise is the Catylic Convert.. I got under the Jimmy and man did it rattle inside it. also you can pound on it with your Fist and it sounds like dice in there. So today for 185 installed we are getting a new one. You can barely beat that price on ebay for one. Hopefully This will be the cure for our issue. We are in the process of having a crank relearn performed. This issue explains why at low RPM and idle it sputters but smooths out. Crank sensor made is so much better with just putting the new one in.

#8

P0300 is almost always caused by a fault in secondary ignition: Plugs, wires, distributor cap, rotor, ignition coil, low fuel pressure and incorrect camshaft retard adjustment. There are other things that can cause it to set, but since the distributor was out, you might have camshaft retard checked and adjusted first.

#9

Captain Hook is spot on.

I'd like to add that in my experiences, other things can cause a p0300 -- I hate this code so very much.

It could be from ignition, to fuel delivery, to engine mechanical.

the 3 blazers I have recently had that had the 300 code was caused by all different problems.

1 was solved by a full tuneup, plugs,wires,cap,rotor.

1 was diagnosed by doing a compression test, and on cylinder #3, we had 0 compression dry test, wet test still 0. Cause: Bent intake valve on cylinder number 3. Fix: New head.

1 (this was just yesterday) was caused by a clogged solid injector on cylinder #4 + a full tuneup. Original code was a p0300, which went away after a full tuneup. p0303 came back afterwards, and another p0300 randomly. Narrowed it down to a clogged solid injector on #3, replaced with a new spider, and she was golden. No codes, no misfire, runs like a champ.

Knock out the basics first. Fuel pressure and leak down test. Ignition test, spark test, and visual inspection. Compression test as well. Also check for vacuum leaks too. Loose or damaged connectors at the fuel injector assembly, etc.

In 2/3 of these cases I had a scanner with live data, and going by STFT I was able to diagnose them correctly. The only one I couldn't use a scanner on was a 95 with the dreaded obd Version 1.5.

Good luck!

I'd like to add that in my experiences, other things can cause a p0300 -- I hate this code so very much.

It could be from ignition, to fuel delivery, to engine mechanical.

the 3 blazers I have recently had that had the 300 code was caused by all different problems.

1 was solved by a full tuneup, plugs,wires,cap,rotor.

1 was diagnosed by doing a compression test, and on cylinder #3, we had 0 compression dry test, wet test still 0. Cause: Bent intake valve on cylinder number 3. Fix: New head.

1 (this was just yesterday) was caused by a clogged solid injector on cylinder #4 + a full tuneup. Original code was a p0300, which went away after a full tuneup. p0303 came back afterwards, and another p0300 randomly. Narrowed it down to a clogged solid injector on #3, replaced with a new spider, and she was golden. No codes, no misfire, runs like a champ.

Knock out the basics first. Fuel pressure and leak down test. Ignition test, spark test, and visual inspection. Compression test as well. Also check for vacuum leaks too. Loose or damaged connectors at the fuel injector assembly, etc.

In 2/3 of these cases I had a scanner with live data, and going by STFT I was able to diagnose them correctly. The only one I couldn't use a scanner on was a 95 with the dreaded obd Version 1.5.

Good luck!

#10

I got the jimmy back today finally and the guy let me borrow his scanner. Its an Actron. So far its showing the P0300 which sucks however I was glad to see the corrlation failure was gone. It absolutely runs like a dog now obviously and its using a lot of fuel. Tonight im going to do a fuel pressure test and check the passenger side plugs. Driver side was ok but the gap was almost closes on them. I was suprised they fired period and threads were damaged a bit. It helped a little bit when I reset the gap. I notice to that cylinder number 5 plug wire when I pull it off the cap while its running it will run smoother but if I do it to any other plug it will just about die. Also when driving the light will start to blink then go back to being on steady. Before all this happened to the woman that owned the vehicle she had transmission work done and all new spider injection done by the dealership. Another thing I notice was the burning smell when I drove it back to the shop. I don't know but just like you fellas said im going to check the simple stuff first.