97 jimmy running extremely rich

#51

Hole bigger???? Need to grind off the "ears" on the OE hold down bracket, or use an old style SBC hold down bracket.

The Crankshaft position sensor relearn on the Solus Pro is in "functional tests".

Camshaft retard you already found in "engine data". There is no "relearn", unless you consider adjusting, (rotating) the distributor a relearn

The Crankshaft position sensor relearn on the Solus Pro is in "functional tests".

Camshaft retard you already found in "engine data". There is no "relearn", unless you consider adjusting, (rotating) the distributor a relearn

#52

nah I was talking about the crank relearn.

what are you talking about grinding off the "ears" ?

I thought in order to adjust the dizzy that you need to make the hole in the hold down bracket bigger to be able to twist it back and forth to get it at 0 degrees.

ohhh I know what you mean now. but it would work both ways right?

what are you talking about grinding off the "ears" ?

I thought in order to adjust the dizzy that you need to make the hole in the hold down bracket bigger to be able to twist it back and forth to get it at 0 degrees.

ohhh I know what you mean now. but it would work both ways right?

Last edited by bam_9_9_9; 02-16-2016 at 10:51 PM.

#53

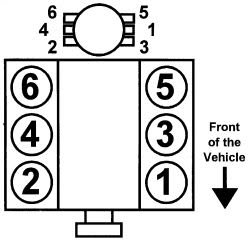

The OE hold down bracket fits around two "flats" on the distributor housing, that's what keeps it from turning. The I.D. of the hole in the intake manifold, is larger than the O.D. of the distributor housing, that's what allows it to turn on an arc. You can remove the OE bracket and grind the "ears" off so the bracket will lay on the round part of the distributor housing, right at the base, and be able to rotate giving you full adjustment to camshaft retard. Once you pull the old one out, you'll see what I'm talking about. Before you pull it out, manually rotate the crank with a socket & ratchet so the rotor lines up with the "6". DON'T rotate the crank, or activate the starter while the distributor is removed. When installing the new distributor, make sure the rotor points at the "6" when it's fully seated against the intake manifold.

#55

Alright . got the new dizzy in and now i cant even get it running to adjust the cmp. Just spits and sputters. Pops once or twice every few rotations. And sometimes backfires loud through the exhaust. So i thought i had it one tooth off. I checked timming and its spot on. Tdc and rotor points to the 6 exactly. Swapped cap and rotor with the new ones i bought. Same thing. Checked spark again and it jumps a half inch gap. It was running like crap a few weeks ago and now its just pops a few times. Exhaust smells like gas after trying to start it

Last edited by bam_9_9_9; 02-28-2016 at 05:47 PM.

#56

Sounds like it's off more than a tooth! Did you follow the suggestion in post #53?

"Before you pull it out, manually rotate the crank with a socket & ratchet so the rotor lines up with the "6". DON'T rotate the crank, or activate the starter while the distributor is removed. When installing the new distributor, make sure the rotor points at the "6"when it's fully seated against the intake manifold."

This is assuming that it's correct to begin with

The distributor and camshaft rotate at the same speed. They make one revolution for every two crankshaft revolutions. #1 piston is at TDC every rotation of the crankshaft. The first time it's on the compression stroke, the next time it's on the exhaust stroke. If you install the distributor at TDC of the exhaust stroke, the engine will pop, fart, sneeze, burp, and backfire when you try to start it The distributor is firing the spark plug at TDC of the exhaust stroke, and it ain’t gonna run

The distributor is firing the spark plug at TDC of the exhaust stroke, and it ain’t gonna run

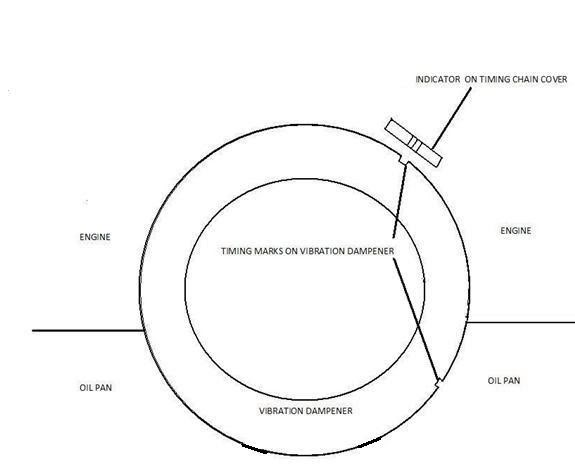

Figuring out which stroke #1 cylinder is on, requires removing the spark plug, disabling the ignition, and the fuel pump, and then crank the starter. While it's cranking, you will hear air "pushing" out of the spark plug hole. On the exhaust stroke, the exhaust valve is open so the "push" is noticeably weaker. On the compression stroke, both valves are closed, causing a much stronger "push", that's the one you need. You need to stop cranking the starter just before the stronger push starts. Then manually rotate the crankshaft clockwise with a socket & ratchet so the dampener marks are aligned like this:

The rotor segment should be pointing at the "6". If not, pull the distributor out, rotate the shaft 180 degrees, and reinstall it so it does.

"Before you pull it out, manually rotate the crank with a socket & ratchet so the rotor lines up with the "6". DON'T rotate the crank, or activate the starter while the distributor is removed. When installing the new distributor, make sure the rotor points at the "6"when it's fully seated against the intake manifold."

This is assuming that it's correct to begin with

The distributor and camshaft rotate at the same speed. They make one revolution for every two crankshaft revolutions. #1 piston is at TDC every rotation of the crankshaft. The first time it's on the compression stroke, the next time it's on the exhaust stroke. If you install the distributor at TDC of the exhaust stroke, the engine will pop, fart, sneeze, burp, and backfire when you try to start it

The distributor is firing the spark plug at TDC of the exhaust stroke, and it ain’t gonna run

The distributor is firing the spark plug at TDC of the exhaust stroke, and it ain’t gonna run

Figuring out which stroke #1 cylinder is on, requires removing the spark plug, disabling the ignition, and the fuel pump, and then crank the starter. While it's cranking, you will hear air "pushing" out of the spark plug hole. On the exhaust stroke, the exhaust valve is open so the "push" is noticeably weaker. On the compression stroke, both valves are closed, causing a much stronger "push", that's the one you need. You need to stop cranking the starter just before the stronger push starts. Then manually rotate the crankshaft clockwise with a socket & ratchet so the dampener marks are aligned like this:

The rotor segment should be pointing at the "6". If not, pull the distributor out, rotate the shaft 180 degrees, and reinstall it so it does.

Last edited by Captain Hook; 02-28-2016 at 10:17 PM.

#60

Can a clogged cat converter burn up the valves and cause low compression?

I was told the engine missed a bit here and there but nothing major. so that may have been how the cat plugged up. also sort of makes sense when number 6 poppet nozzle was melted at the tip.

going to check compression in a few days. anybody know what the cylinders should be at?

I was told the engine missed a bit here and there but nothing major. so that may have been how the cat plugged up. also sort of makes sense when number 6 poppet nozzle was melted at the tip.

going to check compression in a few days. anybody know what the cylinders should be at?