Won't start when weather cold

#1

A friend's 1999 4x4 Lt Blazer

The fuel pump failed and he had it replaced several weeks ago. I don't know what brand. New fuel regulator installed.

Normally, the car starts and runs fine. When the weather gets cold, (about 10F or colder) the engine will try to start once, then just cranks. A bit of fuel in the throttle body will then cause it to start, then die. Warming the engine (block heater) has no effect on cold weather no-start. The weather warms above 10F and it starts every time and runs great. Fuel pressure on initial key on is about 60 psi. We checked the fuel pressure on my Blazer (one year newer) with factory original fuel pump and prestart (ignition on) it was at 64 psi.

Prior to fuel pump failure, it always started.

The company who replaced the fuel pump feels it is not the pump and wants to start with a "tune up" estimated at over $500. Trouble shooting costs added beyond that.

Lots of gas line antifreeze already added.

In my opinion, the problem is fuel related and has nothing to do with the ignition. Is it possible the fuel pressure is slightly low? What else?

Thanks...Tim

The fuel pump failed and he had it replaced several weeks ago. I don't know what brand. New fuel regulator installed.

Normally, the car starts and runs fine. When the weather gets cold, (about 10F or colder) the engine will try to start once, then just cranks. A bit of fuel in the throttle body will then cause it to start, then die. Warming the engine (block heater) has no effect on cold weather no-start. The weather warms above 10F and it starts every time and runs great. Fuel pressure on initial key on is about 60 psi. We checked the fuel pressure on my Blazer (one year newer) with factory original fuel pump and prestart (ignition on) it was at 64 psi.

Prior to fuel pump failure, it always started.

The company who replaced the fuel pump feels it is not the pump and wants to start with a "tune up" estimated at over $500. Trouble shooting costs added beyond that.

Lots of gas line antifreeze already added.

In my opinion, the problem is fuel related and has nothing to do with the ignition. Is it possible the fuel pressure is slightly low? What else?

Thanks...Tim

Last edited by tpolzin; 12-15-2013 at 11:17 AM.

#2

Going to have to check fuel pressure when engine does not start to determine for sure if fuel pump or not.

Wonder if some fuel antifreeze might also help along with fuel injector cleaner added to the tank.

Wonder if some fuel antifreeze might also help along with fuel injector cleaner added to the tank.

#3

Tim, I think you're on the right track with fuel pressure. A bit of fuel in the throttle body, and 60psi are the clues. Fuel pressure needs to be 60psi to 66psi to squirt enough fuel on cold starts. At 10F, 60psi is just barely enough, and if the engine is not tuned well, you'll definitely encounter hard starting. Your reading of 60psi is borderline, and if the gauge reads high, even 1 or 2 psi, you will have cold start problems. It could be the fuel pump is weak, or it could be the regulator is set too low. We need some more numbers from you.

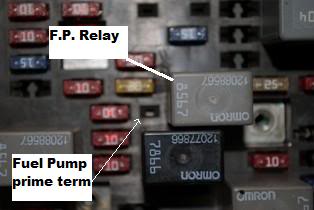

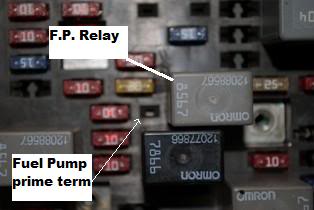

In the underhood fuse panel there is a vacant terminal next to the fuel pump relay. The pump prime circuit goes directly to the fuel pump.

Connect the fuel pressure tester to the service port by the distributor. Connect a fused jumper wire from battery positive to the pump prime terminal. When the fuel pressure stabilizes on the tester, write it down. Disconnect the jumper wire. Wait 10 minutes, and write down the pressure reading. Post the readings.

The next step will be checking maximum fuel pump pressure and leakdown at the fuel filter. The results will determine if the pump is able to supply sufficient pressure, and hold it. If the pump can only produce 60psi, which is what you're getting now, the regulated pressure will only be 60psi. If that's the case, the regulator might be OK. If max pump output is above 60psi, your regulator is set too low. I'll explain how to do all this after we have the regulated pressure and leakdown readings.

In the underhood fuse panel there is a vacant terminal next to the fuel pump relay. The pump prime circuit goes directly to the fuel pump.

Connect the fuel pressure tester to the service port by the distributor. Connect a fused jumper wire from battery positive to the pump prime terminal. When the fuel pressure stabilizes on the tester, write it down. Disconnect the jumper wire. Wait 10 minutes, and write down the pressure reading. Post the readings.

The next step will be checking maximum fuel pump pressure and leakdown at the fuel filter. The results will determine if the pump is able to supply sufficient pressure, and hold it. If the pump can only produce 60psi, which is what you're getting now, the regulated pressure will only be 60psi. If that's the case, the regulator might be OK. If max pump output is above 60psi, your regulator is set too low. I'll explain how to do all this after we have the regulated pressure and leakdown readings.

Last edited by Captain Hook; 12-15-2013 at 01:48 PM.

#4

Ok, warm day today. Temp at about 40 F (3 c). Blazer has been on the road immediately prior for one hour.

Ignition on before starting, 58 PSI. Bypass wire connected with ignition off, 64 PSI. 10 minute leakdown at 58PSI.

Tim

Ignition on before starting, 58 PSI. Bypass wire connected with ignition off, 64 PSI. 10 minute leakdown at 58PSI.

Tim

#6

Only DTC in memory is p0147 on the third o2 sensor. It occasionally crops up, then goes away. Check engine light is normally off. Nothing else in memory or pending.

Engine, even in coldest weather, is relatively warm as it is plugged in with a coolant block heater. It cranks normally. He has even blanketed the engine compartment with a 100 watt trouble light near the spyder and on the same side as the ecu overnight with no help. The temp goes above -10c (about 20 F) and it starts even without being plugged in.

We should repeat those pressure tests in cold weather. One more bit of information. We were able to start it at -27C by cycling the fuel pump twice then it started (ignition on for three secs, off for 1, on for three, off for 1 then start). The first time we did that, it almost started, the second time it started. We had it boosted at the same time. The next morning, he tried boosting it without cycling the fuel pump and it did not start.

Would updating the Spyder assembly with the later MFI unit improve things?

Engine, even in coldest weather, is relatively warm as it is plugged in with a coolant block heater. It cranks normally. He has even blanketed the engine compartment with a 100 watt trouble light near the spyder and on the same side as the ecu overnight with no help. The temp goes above -10c (about 20 F) and it starts even without being plugged in.

We should repeat those pressure tests in cold weather. One more bit of information. We were able to start it at -27C by cycling the fuel pump twice then it started (ignition on for three secs, off for 1, on for three, off for 1 then start). The first time we did that, it almost started, the second time it started. We had it boosted at the same time. The next morning, he tried boosting it without cycling the fuel pump and it did not start.

Would updating the Spyder assembly with the later MFI unit improve things?

#7

Interesting. Checking fuel pessure and leakdown when the problem occurs, like Lanny mentioned, is probably a good idea. This definitely sounds like low fuel pressure, or a lean mixture, which the PCM would detect and set a DTC. Clogged injectors could/would have the same effect, (lean mixture). The MFI update does wonders for this engine, and it may help with this issue. Pretty expensive guess though.

The P0147 will not cause any of this stuff. Without any DTC's in memory, the problem has to be something that is not monitored by the PCM, fuel delivery is not monitored. Now, there could be a difference between ECT, (Engine Coolant Temperature) sensor and the IAT, (Inlet Air Temperature) sensor. If that's the case, that could cause a lean mixture, and NOT set a DTC in memory, provided they are both within range. Rare that would happen, and can be tested easily with a scan tool. When the engine has been off for ~10 hours: Ignition ON, engine OFF, check both sensors. Temps should be within 2 degrees of each other.

The P0147 will not cause any of this stuff. Without any DTC's in memory, the problem has to be something that is not monitored by the PCM, fuel delivery is not monitored. Now, there could be a difference between ECT, (Engine Coolant Temperature) sensor and the IAT, (Inlet Air Temperature) sensor. If that's the case, that could cause a lean mixture, and NOT set a DTC in memory, provided they are both within range. Rare that would happen, and can be tested easily with a scan tool. When the engine has been off for ~10 hours: Ignition ON, engine OFF, check both sensors. Temps should be within 2 degrees of each other.

#8

Perfect. Will check the ECT and AIT as my old MT2500 has that capability. I discounted clogged injectors as the engine runs with a nice smooth idle without any indication of hesitation or miss. A miss would show up as a DTC anyway.

Is the MFI assembly less sensitive to low fuel pressure?

You have been a big help. Thanks

BTW, I grew up in Southfield and went to MSU.

Tim

Is the MFI assembly less sensitive to low fuel pressure?

You have been a big help. Thanks

BTW, I grew up in Southfield and went to MSU.

Tim

#9

1) Block off the return line and see if fuel pressure exceeds 75lbs. or check it at the filter.

2) Check cold start fuel pressure. If you do not have full fuel pressure on a cold start the injectors will not squirt fuel.

Full pressure with return line blocked and low pressure without it blocked may indicate the fuel pressure regulator is leaking or not holding pressure when its cold.

It is just odd that prior to the new pump it didn't have a problem.

#10

Small world! I live about 12 miles from U of M campus, and I'm on MSU campus almost every day!

The original injection system has a poppet nozzle at each intake port, and 6 mini injectors in the fuel metering block in the center of the plenum. The problem is the poppet nozzles get varnished up which causes a restriction, and a screwy spray pattern. Worst case scenario is no spray at all, just droplets of fuel dribbling out. That presents a huge problem when the engine is cold due to no atomization of the fuel. Similar to throwing a log on a fire, or sawdust. It usually happens evenly to each nozzle so you don't notice a problem until it's serious. The injector upgrade totally eliminates the poppet nozzles and relocates the injectors to the intake ports. The result is less of a problem with varnish build up in the nozzles. The benefit is noticeably better performance, and slightly better fuel economy. The upgrade is no less affected by low fuel pressure, but it is less likely to varnish up. The upgrade is plug & play, no programming necessary. Besides the injector assembly, you'll need the upgraded bracket that holds the new metering block, a new plenum gasket, and a new O ring that seals the metering block to the plenum, (oil it before assembly). The Delphi brand injector assembly comes with the bracket, ($20). Amazon & Ebay usually have good prices, make sure they ship to CA.

Go Green!

EDIT: DO NOT block off the fuel return line! If the fuel pressure regulator diaphragm is exposed to ~75psi, it will rupture.

The original injection system has a poppet nozzle at each intake port, and 6 mini injectors in the fuel metering block in the center of the plenum. The problem is the poppet nozzles get varnished up which causes a restriction, and a screwy spray pattern. Worst case scenario is no spray at all, just droplets of fuel dribbling out. That presents a huge problem when the engine is cold due to no atomization of the fuel. Similar to throwing a log on a fire, or sawdust. It usually happens evenly to each nozzle so you don't notice a problem until it's serious. The injector upgrade totally eliminates the poppet nozzles and relocates the injectors to the intake ports. The result is less of a problem with varnish build up in the nozzles. The benefit is noticeably better performance, and slightly better fuel economy. The upgrade is no less affected by low fuel pressure, but it is less likely to varnish up. The upgrade is plug & play, no programming necessary. Besides the injector assembly, you'll need the upgraded bracket that holds the new metering block, a new plenum gasket, and a new O ring that seals the metering block to the plenum, (oil it before assembly). The Delphi brand injector assembly comes with the bracket, ($20). Amazon & Ebay usually have good prices, make sure they ship to CA.

Go Green!

EDIT: DO NOT block off the fuel return line! If the fuel pressure regulator diaphragm is exposed to ~75psi, it will rupture.

Last edited by Captain Hook; 12-15-2013 at 08:47 PM.