Help on a 1995 Jimmy 4L60E Transmission Problem

#1

Details: I have a 1995 GMC Jimmy with 4L60E transmission with about 235,000 miles. I was occasionally losing overdrive when driving so I dropped the pan. The was actually pretty clean with not much so I think the clutches were fine.

I took the valve body all apart, cleaned, bought Sonnex 1,2 2-3 accumulators for install and took apart the 2-4 servo. I bought an overhaul kit for all the seals, etc to get it all put back together

I put it all back together and now the Jimmy will start out in first gear normal, reverse works perfect and when putting it into gear it will go into forward and reverse quickly, but when I drive it will not go into 2nd Gear at all, neither manually or automatically. When driving in 1st you have to rev it up high and then let off gas and it will shift into 3rd gear. It does not go into 4th now, it only stays in 3rd (drive) with no torque converter lock-up.

What could I of screwed up putting back together incorrectly? Since now I basically don't have 2nd gear or 4th gear.

It can't be the clutches correct since it's not shifting into 2nd gear and if it was the clutches in 2nd and 4th would the engine just rev like its free-wheeling?

Any help greatly appreciated!!!!

I took the valve body all apart, cleaned, bought Sonnex 1,2 2-3 accumulators for install and took apart the 2-4 servo. I bought an overhaul kit for all the seals, etc to get it all put back together

I put it all back together and now the Jimmy will start out in first gear normal, reverse works perfect and when putting it into gear it will go into forward and reverse quickly, but when I drive it will not go into 2nd Gear at all, neither manually or automatically. When driving in 1st you have to rev it up high and then let off gas and it will shift into 3rd gear. It does not go into 4th now, it only stays in 3rd (drive) with no torque converter lock-up.

What could I of screwed up putting back together incorrectly? Since now I basically don't have 2nd gear or 4th gear.

It can't be the clutches correct since it's not shifting into 2nd gear and if it was the clutches in 2nd and 4th would the engine just rev like its free-wheeling?

Any help greatly appreciated!!!!

#2

The 2-4 servo is the only common part between your two issues. That is used to apply the band. If you want to refer to a thread I started: 700r4/4l60e things I've Learned, I posted a picture of the clutch application chart as well as a complete fluid circuit diagram.

I'm going to guess that something went wrong when you were working on the 2-4 servo. That would be where you want to double check your work and make sure you didn't install a seal backwards. If that turns up good, did you make sure the retaining pin did not drop out while you had the valvebody apart? It was the steel plug that is towards the front which holds the band in place. If that dropped out and allowed the band to move, it would not keep the band retained and when the 2-4 pin applies. This would not squeeze around the forward drum and there would be no 2nd or 4th gears.

I'm going to guess that something went wrong when you were working on the 2-4 servo. That would be where you want to double check your work and make sure you didn't install a seal backwards. If that turns up good, did you make sure the retaining pin did not drop out while you had the valvebody apart? It was the steel plug that is towards the front which holds the band in place. If that dropped out and allowed the band to move, it would not keep the band retained and when the 2-4 pin applies. This would not squeeze around the forward drum and there would be no 2nd or 4th gears.

#3

TZFBird,

I will definitely take apart the 2-4 servo and make sure i have it all installed correctly. Is there a way that i could of installed the 2 servo parts in reverse on the pin do you think? It was a B*tch getting the cover back on and the ring in with it in there and took me an hour at least, so maybe I screwed it up...

I took a large amount of time putting it back together so who knows..

Would a putting the accumulators together wrong cause it?

I will definitely take apart the 2-4 servo and make sure i have it all installed correctly. Is there a way that i could of installed the 2 servo parts in reverse on the pin do you think? It was a B*tch getting the cover back on and the ring in with it in there and took me an hour at least, so maybe I screwed it up...

I took a large amount of time putting it back together so who knows..

Would a putting the accumulators together wrong cause it?

#5

Update on issue:

I TOOK APART THE 2-4 SERVO: First the 4th apply servo (the first servo in the cover was missing the Teflon seal and was off of the actual 4th apply servo and inside the housing next to the 2nd apply piston, so that seal was totally off the piston!

Then the 2nd apply piston (large Teflon seal) was also missing off of the 2nd apply piston and that Teflon seal it was pushed up next to the rubber seal on the Inner Housing seal!

So what would cause this????? There is a lot of tolerance in the 4th apply piston aluminum when placed in he housing without the Teflon seal, so is that worn out? Help!

I TOOK APART THE 2-4 SERVO: First the 4th apply servo (the first servo in the cover was missing the Teflon seal and was off of the actual 4th apply servo and inside the housing next to the 2nd apply piston, so that seal was totally off the piston!

Then the 2nd apply piston (large Teflon seal) was also missing off of the 2nd apply piston and that Teflon seal it was pushed up next to the rubber seal on the Inner Housing seal!

So what would cause this????? There is a lot of tolerance in the 4th apply piston aluminum when placed in he housing without the Teflon seal, so is that worn out? Help!

#6

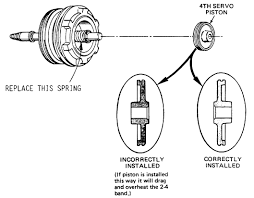

This is the location and what the pin looks like.

Make sure the 4th piston was not installed backwards also.

I don't know how the seals could come completely off the pistons. Unfortunately without seeing the part I can't tell you for sure as far as tollerances. After looking at some pics I'm starting to remember... it's been a while since I've worked on one of these. Could the seals have came out during installation? Since they are a split style they will open up and could have got snagged and pulled out of the groove? I use Vasoline to retain parts in place during installation. It's sticky enough to hold things in place but it dissolves into the transmission fluid. Unless something is completely wrong with the bore in the case I don't think the seals should just fall off like that. Make sure everything is oriented properly and try again using Vasoline to hold parts in place during assembly.

Good luck. If you need new parts there are a few sites that sell individual parts. Otherwise I have been able to visit a local transmission shop that had a few spare seals laying around when I've got into a bind.

Make sure the 4th piston was not installed backwards also.

I don't know how the seals could come completely off the pistons. Unfortunately without seeing the part I can't tell you for sure as far as tollerances. After looking at some pics I'm starting to remember... it's been a while since I've worked on one of these. Could the seals have came out during installation? Since they are a split style they will open up and could have got snagged and pulled out of the groove? I use Vasoline to retain parts in place during installation. It's sticky enough to hold things in place but it dissolves into the transmission fluid. Unless something is completely wrong with the bore in the case I don't think the seals should just fall off like that. Make sure everything is oriented properly and try again using Vasoline to hold parts in place during assembly.

Good luck. If you need new parts there are a few sites that sell individual parts. Otherwise I have been able to visit a local transmission shop that had a few spare seals laying around when I've got into a bind.

#8

If you do buy the Corvette servo compare the two and let me know if there is a size difference. The ones I have been buying do not have a noticable difference than what was originally in the transmission. Maybe I've been buying something labeled as a "corvette" servo and it's actually not.

#9

I'll take a picture of what I get for the "Corvette" servo, "bought it off of Amazon for $13.00 shipped and my old one. I already know it's bigger because mine is 1995 transmission. In the later 2000s year 4L60e transmissions they all started getting the corvette servo size put in all of them. Just researched it, so that is probably why you didn't see a difference. I am attaching a picture for you of all the 4L60E 2-4 Servo Sizes from GM, since you have helped my friend..

Reading you don't want to big of 2nd apply servo, so the best all around listed on the internet is the Sonnex brand.

Since I have so much play in my old 4th servo/2-4 servo cover, I am going to put in a new 4th gear servo, probably a:

Superior GM 700R4 4L60E 4L65E Billet Super Servo 4th Gear Apply Piston & Cover Overdrive 700-R4 4L60, they are alot cheaper on Ebay.

I also have a never used T700 4th B&M billet super servo that's at my dad's house I'm going to go get tonight. I bought it for my old 1983 Camaro 20+ years ago and never used it, so if it works I may use that! I think I know exactly where it is after all this time :-)

Reading you don't want to big of 2nd apply servo, so the best all around listed on the internet is the Sonnex brand.

Since I have so much play in my old 4th servo/2-4 servo cover, I am going to put in a new 4th gear servo, probably a:

Superior GM 700R4 4L60E 4L65E Billet Super Servo 4th Gear Apply Piston & Cover Overdrive 700-R4 4L60, they are alot cheaper on Ebay.

I also have a never used T700 4th B&M billet super servo that's at my dad's house I'm going to go get tonight. I bought it for my old 1983 Camaro 20+ years ago and never used it, so if it works I may use that! I think I know exactly where it is after all this time :-)