99 Jimmy Wont start

#1

I just bought a 99 gmc jimmy with 146,000 that the previous owner said he was driving along and it just died. It cranks over good but backfires thru the intake and then cranks hard for a second. Has no codes in ecm. Guy before me replaced plugs,wires, distributor, and cranks sensor, I replaced fuel filter, checked timing on distributor and distributor turn when turning engine over by hand, checked fuel pressure(good has 60psi and holds between 60 and 55 for good amount of time) and fuel pump runs good, seems to have good spark when using inline spark tester, swapped ecm with one from my blazer and coil and icm,cleaned iac valve as it was dirty. have not found any blown fuses. i Have even tried a different battery as the one that came with vehicle is getting a little weak.I am hoping someone had some ideas on what to do next or what may be the issue or have had the same problem in past. Would it have to do with possible timing chain jumping teeth and is there any way to tell if it chain has jumped without tearing down to timing chain?

#3

Distributor cap & rotor need to be AC Delco. Aftermarket stuff doesn't cut it on these engines. Very likely that is the problem.

If the crankshaft position sensor or timing cover is moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed, (requires a scan tool capable of initiating the relearn). Same holds true with the PCM.

Extremely doubtful the timing chain jumped. There is a way to check it without any engine disassembly though.

Start with the distributor cap & rotor. Make sure you put silicone dielectric grease on all terminals, inside and out. Post your results.

If the crankshaft position sensor or timing cover is moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed, (requires a scan tool capable of initiating the relearn). Same holds true with the PCM.

Extremely doubtful the timing chain jumped. There is a way to check it without any engine disassembly though.

Start with the distributor cap & rotor. Make sure you put silicone dielectric grease on all terminals, inside and out. Post your results.

#5

Distributor cap & rotor need to be AC Delco. Aftermarket stuff doesn't cut it on these engines. Very likely that is the problem.

If the crankshaft position sensor or timing cover is moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed, (requires a scan tool capable of initiating the relearn). Same holds true with the PCM.

Extremely doubtful the timing chain jumped. There is a way to check it without any engine disassembly though.

Start with the distributor cap & rotor. Make sure you put silicone dielectric grease on all terminals, inside and out. Post your results.

If the crankshaft position sensor or timing cover is moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed, (requires a scan tool capable of initiating the relearn). Same holds true with the PCM.

Extremely doubtful the timing chain jumped. There is a way to check it without any engine disassembly though.

Start with the distributor cap & rotor. Make sure you put silicone dielectric grease on all terminals, inside and out. Post your results.

#6

Distributor cap & rotor need to be AC Delco. Aftermarket stuff doesn't cut it on these engines. Very likely that is the problem.

If the crankshaft position sensor or timing cover is moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed, (requires a scan tool capable of initiating the relearn). Same holds true with the PCM.

Extremely doubtful the timing chain jumped. There is a way to check it without any engine disassembly though.

Start with the distributor cap & rotor. Make sure you put silicone dielectric grease on all terminals, inside and out. Post your results.

If the crankshaft position sensor or timing cover is moved, removed, replaced, or disturbed in any way, the crankshaft position sensor relearn must be performed, (requires a scan tool capable of initiating the relearn). Same holds true with the PCM.

Extremely doubtful the timing chain jumped. There is a way to check it without any engine disassembly though.

Start with the distributor cap & rotor. Make sure you put silicone dielectric grease on all terminals, inside and out. Post your results.

Ok had to order cap and rotor. Installed new ac delco cap and rotor. Engine cranks over faster and attempts to start then i hear a loud knock and starter then has a hard time turning engine over at that time.possible bent or broken valve?

#7

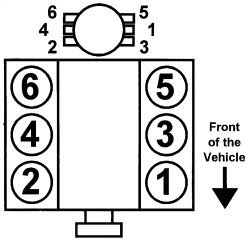

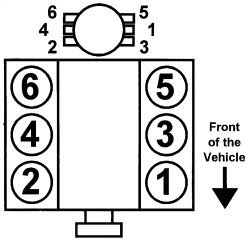

Double check the spark plug wiring.

Pay close attention to cylinders 1 & 3

on the distributor cap.

If that checks out ok, unplug the electrical

connector from the ignition module and

try to start it. See if it knocks or there is

a hard time turning the engine over.

Pay close attention to cylinders 1 & 3

on the distributor cap.

If that checks out ok, unplug the electrical

connector from the ignition module and

try to start it. See if it knocks or there is

a hard time turning the engine over.

Last edited by Captain Hook; 01-11-2016 at 07:38 PM.

#8

Ok checked plug wiring all looks good.unplugged ignition module and it turns over great and no more nock

#9

Unplugging the ignition module disables the ignition: If the engine turns over fine, with no knock, it tells us the no-start and knock noise are ignition related. If you're absolutely sure the plug wires are correctly routed, the next thing to check, is the rotor. The under side of the rotor was designed so that it can only be installed one way. Unfortunately, it IS possible to install it 180 degrees out of phase. If this happens, the starter will "fight" the ignition, and the engine will not start.

The knock sound you're hearing, is actually a cylinder firing with both valves closed, which makes it very difficult for the starter to continue cranking the engine.

The knock sound you're hearing, is actually a cylinder firing with both valves closed, which makes it very difficult for the starter to continue cranking the engine.

#10

Unplugging the ignition module disables the ignition: If the engine turns over fine, with no knock, it tells us the no-start and knock noise are ignition related. If you're absolutely sure the plug wires are correctly routed, the next thing to check, is the rotor. The under side of the rotor was designed so that it can only be installed one way. Unfortunately, it IS possible to install it 180 degrees out of phase. If this happens, the starter will "fight" the ignition, and the engine will not start.

The knock sound you're hearing, is actually a cylinder firing with both valves closed, which makes it very difficult for the starter to continue cranking the engine.

The knock sound you're hearing, is actually a cylinder firing with both valves closed, which makes it very difficult for the starter to continue cranking the engine.

Is that all correct?