How difficult to replace A/C CONDENSER?

#31

R134a mixes with PAG150 and thins it out immediately. The oil is in suspension with the refrigerant. It uses the refrigerant to circulate it through the system.

Does the manifold gauge set that you're using look like the one in the video with an aluminum block for the manifold? Does it have that style of "valves"? Is there a sight glass? It could very well have messed up valves.

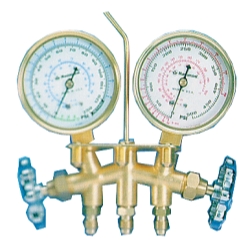

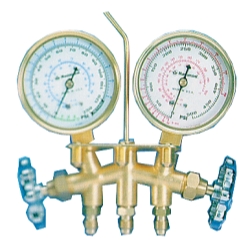

This style is FAR better than the aluminum block ones. The manifold is brass, and the valves are "real valves". AZ stuff is not known for its quality.

Does the manifold gauge set that you're using look like the one in the video with an aluminum block for the manifold? Does it have that style of "valves"? Is there a sight glass? It could very well have messed up valves.

This style is FAR better than the aluminum block ones. The manifold is brass, and the valves are "real valves". AZ stuff is not known for its quality.

#32

Pics below...it's very similar to the one in the video. I didn't get off to a good start when them. I thought I had a leak in the system because I wasn't getting to 29" Hg and it wasn't holding vacuum at all. After rechecking the fittings on the accumulator I stopped before getting into the meat of rechecking all the connections and checked the manifold gauge hoses. Sure enough the blue hose was not tight enough going into the fitting of the aluminum block. I'm guessing that previous users overtightened the fitting and made mush of the gaskets. My only choice was to use pliers to get them really tight to stop the leak. That's partially the reason why I'll pick up a brand new set of gauges and try again.

#33

Yup, those things are just below entry level  They're fine if you want to hang 'em on the wall so people think you do AC work. If you want a good laugh, take one of those ***** off and check out what they call a "valve", definitely comedy. You can check Ebay for the brass style manifold set. You don't need to spend a fortune, but you need good quality, dependable equipment. Yellow Jacket & Robinair make good quality stuff, but they do have entry level stuff too, stay away from the aluminum block jobbies.

They're fine if you want to hang 'em on the wall so people think you do AC work. If you want a good laugh, take one of those ***** off and check out what they call a "valve", definitely comedy. You can check Ebay for the brass style manifold set. You don't need to spend a fortune, but you need good quality, dependable equipment. Yellow Jacket & Robinair make good quality stuff, but they do have entry level stuff too, stay away from the aluminum block jobbies.

They're fine if you want to hang 'em on the wall so people think you do AC work. If you want a good laugh, take one of those ***** off and check out what they call a "valve", definitely comedy. You can check Ebay for the brass style manifold set. You don't need to spend a fortune, but you need good quality, dependable equipment. Yellow Jacket & Robinair make good quality stuff, but they do have entry level stuff too, stay away from the aluminum block jobbies.

They're fine if you want to hang 'em on the wall so people think you do AC work. If you want a good laugh, take one of those ***** off and check out what they call a "valve", definitely comedy. You can check Ebay for the brass style manifold set. You don't need to spend a fortune, but you need good quality, dependable equipment. Yellow Jacket & Robinair make good quality stuff, but they do have entry level stuff too, stay away from the aluminum block jobbies.

#34

Well, the job is complete. What a PITA! The sad thing is, for this vehicle, it SHOULD BE one of the easiest A/C jobs that one can do on a vehicle. All the components are fairly easy to get to ... not really a knuckle buster nor a job that requires you to contort your body. But I ran into problem after problem some of which you'd expect on a vehicle this old that has faced the hot Florida sun for 18 years.

1. The accumulator connection from the evaporator was seized on pretty good. I didn't have to take extreme measure but it did take a couple of hours of squirting it with liquid wrench, et al and working the wrenches back-n-forth on the nut to get it loose. Not unexpected so I found this to be a reasonable problem.

2. The plastics in the engine compartment certainly have become brittle in many places. I had a heck of a time getting the high pressure sensor on the back of the old compressor to come out even though all you should have to do is remove the snap ring then gently wiggle it out. When I finally got it out I discovered the plastic was cracked on the electrical connector fitting and not worth the risk of reusing so I had to buy a new one.

3. When I went to plug in the electrical connector to the the high pressure sensor on the compressor I discovered the plastic latch on the connector missing. Lucky it never popped loose but I found reusing it not worth the potential complaint from the G/F if it popped off. So I had to buy a new one and do some splicing/soldering. Not difficult but this simple job is starting to become a PITA.

4. Ordered a new condenser but when the box was opened up I found it was bent by FedEx so had to send it back to the seller and wait on a replacement to show up. Got the replacement installed but because the new one had the tubing on the inlet side routed so slightly different than the original I had a problem getting the radiator back in. However, I did get the radiator in but was so lucky it went in because the condenser inlet tube is basically resting right up against the side of the radiator. I hope it doesn't rub a hole in plastic over time causing a leak.

5. I decided it wasn't worth reusing the old a/c hose assembly so I purchased a new one. While installing it I discover the new one, like the condenser issue, had the tubing coming from the a/c hose manifold bent such that it hit and rested on top of the front/left bolt of the compressor not allowing you to bolt the a/c hose manifold onto the compressor. I had to drive around town to 5 auto parts store before I found one constructed similar to the original. The high pressure side of this hose assembly where it connected to the condenser also was slightly different from the original such that (of course) it interfered with the transmission cooling line going into the radiator. I had to manipulate it to get all the lines connected.

6. The final insulting PITA was dealing with the manifold gauge set I rented from AutoZone. The blue and yellow hoses leaked. You had to use pliers to tighten the fittings to get them to stop leaking (not a good idea) but you have to do what you have to do. But when you did that I think it squished the plastic washers so much they blocked the path through the hoses. This is what happened earlier when I was trying to figure out why the system wasn't charging properly and perhaps not vacuumed properly. This ain't rocket science and with the proper "working" manifold gauge set this process should have been easy. So I ran out and picked up a new manifold gauge set figuring that should take care of my problem with crappy tools. Sadly, the new manifold gauge set was leaking on the high pressure connection to the service port. I must have spent five hours yesterday tinkering around while trying to vacuum the system before I finally figured out what was working and not working with the two different gauge sets. I thought I had a vacuum leak in the system when if fact it was the new gauge set and there was nothing I could do to fix the leak on high pressure service port connector. I ended up using the blue and yellow hoses from the new set and the red hose on the rented set. That's right ... I had half of one set and half of the other set and two sets of gauges hanging from the hood.

Anyhow, the job is done. I'm hoping the G/F can report the a/c is ice cold when you tries to use it.

Thank you for your help!

1. The accumulator connection from the evaporator was seized on pretty good. I didn't have to take extreme measure but it did take a couple of hours of squirting it with liquid wrench, et al and working the wrenches back-n-forth on the nut to get it loose. Not unexpected so I found this to be a reasonable problem.

2. The plastics in the engine compartment certainly have become brittle in many places. I had a heck of a time getting the high pressure sensor on the back of the old compressor to come out even though all you should have to do is remove the snap ring then gently wiggle it out. When I finally got it out I discovered the plastic was cracked on the electrical connector fitting and not worth the risk of reusing so I had to buy a new one.

3. When I went to plug in the electrical connector to the the high pressure sensor on the compressor I discovered the plastic latch on the connector missing. Lucky it never popped loose but I found reusing it not worth the potential complaint from the G/F if it popped off. So I had to buy a new one and do some splicing/soldering. Not difficult but this simple job is starting to become a PITA.

4. Ordered a new condenser but when the box was opened up I found it was bent by FedEx so had to send it back to the seller and wait on a replacement to show up. Got the replacement installed but because the new one had the tubing on the inlet side routed so slightly different than the original I had a problem getting the radiator back in. However, I did get the radiator in but was so lucky it went in because the condenser inlet tube is basically resting right up against the side of the radiator. I hope it doesn't rub a hole in plastic over time causing a leak.

5. I decided it wasn't worth reusing the old a/c hose assembly so I purchased a new one. While installing it I discover the new one, like the condenser issue, had the tubing coming from the a/c hose manifold bent such that it hit and rested on top of the front/left bolt of the compressor not allowing you to bolt the a/c hose manifold onto the compressor. I had to drive around town to 5 auto parts store before I found one constructed similar to the original. The high pressure side of this hose assembly where it connected to the condenser also was slightly different from the original such that (of course) it interfered with the transmission cooling line going into the radiator. I had to manipulate it to get all the lines connected.

6. The final insulting PITA was dealing with the manifold gauge set I rented from AutoZone. The blue and yellow hoses leaked. You had to use pliers to tighten the fittings to get them to stop leaking (not a good idea) but you have to do what you have to do. But when you did that I think it squished the plastic washers so much they blocked the path through the hoses. This is what happened earlier when I was trying to figure out why the system wasn't charging properly and perhaps not vacuumed properly. This ain't rocket science and with the proper "working" manifold gauge set this process should have been easy. So I ran out and picked up a new manifold gauge set figuring that should take care of my problem with crappy tools. Sadly, the new manifold gauge set was leaking on the high pressure connection to the service port. I must have spent five hours yesterday tinkering around while trying to vacuum the system before I finally figured out what was working and not working with the two different gauge sets. I thought I had a vacuum leak in the system when if fact it was the new gauge set and there was nothing I could do to fix the leak on high pressure service port connector. I ended up using the blue and yellow hoses from the new set and the red hose on the rented set. That's right ... I had half of one set and half of the other set and two sets of gauges hanging from the hood.

Anyhow, the job is done. I'm hoping the G/F can report the a/c is ice cold when you tries to use it.

Thank you for your help!

#35

Nice

The line rubbing against the radiator WILL be a problem in the near future. Vibration will wear a hole in the aluminum line, radiator, or both. Very common for the lines/fittings to need a little "tweek" so they clear other components. Even the OEM lines from the dealer.

The stubborn fittings can be blamed on a combination of two things: 1. Moisture in the system that wasn't completely removed during the previous evacuation. 2. failure to lubricate the fittings and O rings with 525 viscosity oil, (NOT PAG150) prior to assembly.

AC work is not as simple and easy as one would think, (quality tools & equipment does help though). If it was simple and easy, it would be far less expensive to hire it done . Good job sticking with it! Definitely a learning experience!

. Good job sticking with it! Definitely a learning experience!

The line rubbing against the radiator WILL be a problem in the near future. Vibration will wear a hole in the aluminum line, radiator, or both. Very common for the lines/fittings to need a little "tweek" so they clear other components. Even the OEM lines from the dealer.

The stubborn fittings can be blamed on a combination of two things: 1. Moisture in the system that wasn't completely removed during the previous evacuation. 2. failure to lubricate the fittings and O rings with 525 viscosity oil, (NOT PAG150) prior to assembly.

AC work is not as simple and easy as one would think, (quality tools & equipment does help though). If it was simple and easy, it would be far less expensive to hire it done

. Good job sticking with it! Definitely a learning experience!

. Good job sticking with it! Definitely a learning experience!

Thread

Thread Starter

Forum

Replies

Last Post

snosh

Audio/Video Electronics

1

09-28-2009 03:15 PM