I Pulled Them Top Plenum And Found This...

#12

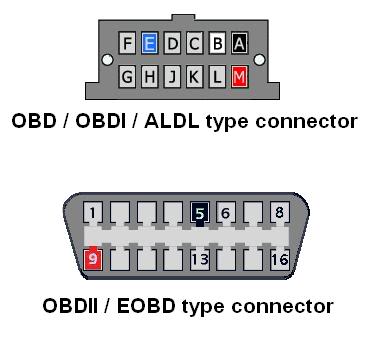

EDIT: I think I've got the "OBD 1.5".

Haha. I work in marketing, I'm used to capping titles - not used to the etiquette around here yet. I was going to go with...

"I Pulled The Plenum - What Happened Next Will SHOCK You..." Or "This One Weird Trick Saved Me $1,000 In Repair Bills". But I decided to subdue it, worked out, got more great replies than I expected. Didn't mean to capninja anyone.

So I'm kind of learning that basically everything in this Blazer has to be a major PITA. Pulling the Plenum was actually the easiest/most straightforward thing I've done on it.

About a month ago my starter went out. I thought "no problem, 2 bolts, 20 minutes and she'll be fine." I was wrong. After about 30 minutes trying to wiggle the stupid starter out, and another hour scouring the web I learned that you have to pull out the entire bell-housing. 20 minutes turned into around 3 hours.

Thought I may have a stuck EGR valve last week. I swear to god I had to hand turn that left bolt with a little box wrench a centimeter at at time. There was no way to fit a socket down there, and it easily took 20 minutes of cranking that thing to get it out. Finally did though.

I made the same mistake today with oil. I don't have any jack-stands, but I foolishly assumed that even with the 3" of vertical space to work under there that getting the drain plug out would be no problem. Well I warmed it up, covered it in WD40 and finally gave up after about 45 minutes of trying to break it loose - even with a breaker-bar and hammering it with a mallet, I'll gladly pay the shop to deal with that.

And I just tried to install my new PCV valve and tubing. I haven't learned my lesson yet because I was thinking "this will take 2 minutes tops". I've gotta be missing 2" on that tube somewhere. I'm going to have to make an extension out of the old tubing/adapter to make it fit.

I briefly thought about changing my own plugs and wires before realizing that I really don't want to submit myself to one more second of torture from the sadistic bastard who designed my truck.

/Rant. Going to try to get this stupid PCV valve on tonight. I really do appreciate all of the help here. Both from your guy's posts and hours of lurking and learning from other people dealing with these issues. Hopefully I'll be reporting back that she's running like brand new tomorrow - not getting my hopes up too high though.

Last edited by Scott23412; 02-14-2014 at 09:48 AM.

#13

Good news. I think - maybe.

So I get it back from the shop - they changed the oil. I drove it to Orielly's to get a working fuel pressure tester and a scan tool.

First of all, the car is running/driving better than it has in the 2 years I've owned it. It ran great, I drove it around for at least a half an hour. It idles smooth. No hesitation. Great acceleration.

So I get the test kit at Oreilly's. Now this *might* be user error, I'd never done this before, didn't know the ideal numbers, just wrote down what I got. I turned the key on a couple of times to kick on the fuel pump. When it hit 50psi I stopped - I thought I remembered that sounding right. Key off, held steady at ~45psi for 10 minutes.

Engine on, I didn't open up the throttle - but again steady at 50psi.

I'm thinking I need to try this again and make sure I use a different pressure kit (just in case) and make sure I follow the instructions (I didn't have them handy). But assuming my fuel pressure is 10psi low what could that mean?

After that I borrowed their OBD scan tool. It showed codes P1406, P0122, P0131. I cleared the codes, check engine light went off. On my drive home, I was thinking "this is awesome! No CEL! It's running great! And then about 10 minutes in the CEL started flashing at me again. Was still running great though. I drove it home and now it's parked.

Not a single misfire, stutter, hesitation - nothing. Ran better than I've ever seen it run. I that PCV valve I broke was a lucky mistake, the old one wasn't in good shape at all.

I have to leave for work soon, I'll be taking a borrowed car. Any advice on what to do next would be much appreciated. I'm thinking re-do the leak down test and scan it again to see if it's storing any codes related to the light flashing. One thought I had is that there was a TON of fuel shooting directly into the cylinders, maybe it's still working on burning through it?

Again, thank you guys so much. Soooo close (I hope).

EDIT: Guessing Fuel Filter/Pump are likely culprits? The CEL flashing freaks me out.

So I get it back from the shop - they changed the oil. I drove it to Orielly's to get a working fuel pressure tester and a scan tool.

First of all, the car is running/driving better than it has in the 2 years I've owned it. It ran great, I drove it around for at least a half an hour. It idles smooth. No hesitation. Great acceleration.

So I get the test kit at Oreilly's. Now this *might* be user error, I'd never done this before, didn't know the ideal numbers, just wrote down what I got. I turned the key on a couple of times to kick on the fuel pump. When it hit 50psi I stopped - I thought I remembered that sounding right. Key off, held steady at ~45psi for 10 minutes.

Engine on, I didn't open up the throttle - but again steady at 50psi.

I'm thinking I need to try this again and make sure I use a different pressure kit (just in case) and make sure I follow the instructions (I didn't have them handy). But assuming my fuel pressure is 10psi low what could that mean?

After that I borrowed their OBD scan tool. It showed codes P1406, P0122, P0131. I cleared the codes, check engine light went off. On my drive home, I was thinking "this is awesome! No CEL! It's running great! And then about 10 minutes in the CEL started flashing at me again. Was still running great though. I drove it home and now it's parked.

Not a single misfire, stutter, hesitation - nothing. Ran better than I've ever seen it run. I that PCV valve I broke was a lucky mistake, the old one wasn't in good shape at all.

I have to leave for work soon, I'll be taking a borrowed car. Any advice on what to do next would be much appreciated. I'm thinking re-do the leak down test and scan it again to see if it's storing any codes related to the light flashing. One thought I had is that there was a TON of fuel shooting directly into the cylinders, maybe it's still working on burning through it?

Again, thank you guys so much. Soooo close (I hope).

EDIT: Guessing Fuel Filter/Pump are likely culprits? The CEL flashing freaks me out.

Last edited by Scott23412; 02-14-2014 at 11:52 AM.

#14

You have OBD1.5 engine controls. Disconnecting the battery will not clear DTC's in the history file. Hard faults and pending fault files are the only files that will be cleared.

The flashing CEL is indicating a misfire that will damage the catalytic converter if it's not repaired. There will be a DTC in memory, even if the light is off when you retrieve the codes.

Fuel pressure: Check it again using the procedure in post #7 and post the pressures. Regulated pressure at 50psi is too low, and leakdown after 10 minutes at 45psi is also too low. There are no "engine running" fuel pressure specs for this engine, all tests are done with the engine off.

The flashing CEL is indicating a misfire that will damage the catalytic converter if it's not repaired. There will be a DTC in memory, even if the light is off when you retrieve the codes.

Fuel pressure: Check it again using the procedure in post #7 and post the pressures. Regulated pressure at 50psi is too low, and leakdown after 10 minutes at 45psi is also too low. There are no "engine running" fuel pressure specs for this engine, all tests are done with the engine off.

Last edited by Captain Hook; 02-14-2014 at 03:12 PM.

#15

You have OBD1.5 engine controls. Disconnecting the battery will not clear DTC's in the history file. Hard faults and pending fault files are the only files that will be cleared.

The flashing CEL is indicating a misfire that will damage the catalytic converter if it's not repaired. There will be a DTC in memory, even if the light is off when you retrieve the codes.

Fuel pressure: Check it again using the procedure in post #7 and post the pressures. Regulated pressure at 50psi is too low, and leakdown after 10 minutes at 45psi is also too low. There are no "engine running" fuel pressure specs for this engine, all tests are done with the engine off.

The flashing CEL is indicating a misfire that will damage the catalytic converter if it's not repaired. There will be a DTC in memory, even if the light is off when you retrieve the codes.

Fuel pressure: Check it again using the procedure in post #7 and post the pressures. Regulated pressure at 50psi is too low, and leakdown after 10 minutes at 45psi is also too low. There are no "engine running" fuel pressure specs for this engine, all tests are done with the engine off.

I did the test again with a different kit, same results. I tried keying on/off multiple times to get it to prime past 50psi, that's as high as she'll go. Leaked down to ~48psi after 10 minutes. I followed your instructions to the letter.

It's still flashing the CEL after about 2 minutes of running.

Scanned again (different scanner too), only pulled a code related the intake air temp sensor (P0112 I think).

I just noticed a lot of blue smoke coming out of the tail pipe too. I'm not sure if it's a new thing (It's been cold lately - it's been billowing white smoke and I haven't paid much attention to it until now).

I put some "Restore" stuff in the oil hoping that may help. No idea yet.

Any suggestions or ideas?

Thanks!

#16

Regulated pressure at 50psi is too low. The cause can be one of two things: either the pump is only able to build 50psi, or the regulator is set too low. You'll need to do some "creative plumbing" so the pressure tester connects directly to the fuel filter outlet. All fuel pressure and flow must end at the tester, (no fuel allowed to the engine). After the tester is connected, cycle the ignition on and off a few times to pressurize the system up to the tester. Then turn the ignition to the run position and write down the pressure while the pump is running, (pump only runs for ~2 seconds and shuts off). Wait 10 minutes and write the pressure reading down. Do not activate the pump during the 10 minute wait period. Post both readings. This will tell us what the problem is.

EDIT:

Most auto parts stores will have Dorman #800-170 in stock. It connects to the fuel filter outlet. Home Depot & Lowes have the brass adapters in the plumbing section. Watts #'s are LFA-116 & LFA-80. These two, along with the Dorman, will adapt the tester. Total cost ~$12.00 These parts will work on 1996 and older S/T series vehicles.

EDIT:

Most auto parts stores will have Dorman #800-170 in stock. It connects to the fuel filter outlet. Home Depot & Lowes have the brass adapters in the plumbing section. Watts #'s are LFA-116 & LFA-80. These two, along with the Dorman, will adapt the tester. Total cost ~$12.00 These parts will work on 1996 and older S/T series vehicles.

Last edited by Captain Hook; 02-15-2014 at 04:55 PM.

#17

Regulated pressure at 50psi is too low. The cause can be one of two things: either the pump is only able to build 50psi, or the regulator is set too low. You'll need to do some "creative plumbing" so the pressure tester connects directly to the fuel filter outlet. All fuel pressure and flow must end at the tester, (no fuel allowed to the engine). After the tester is connected, cycle the ignition on and off a few times to pressurize the system up to the tester. Then turn the ignition to the run position and write down the pressure while the pump is running, (pump only runs for ~2 seconds and shuts off). Wait 10 minutes and write the pressure reading down. Do not activate the pump during the 10 minute wait period. Post both readings. This will tell us what the problem is.

EDIT:

Most auto parts stores will have Dorman #800-170 in stock. It connects to the fuel filter outlet. Home Depot & Lowes have the brass adapters in the plumbing section. Watts #'s are LFA-116 & LFA-80. These two, along with the Dorman, will adapt the tester. Total cost ~$12.00 These parts will work on 1996 and older S/T series vehicles.

EDIT:

Most auto parts stores will have Dorman #800-170 in stock. It connects to the fuel filter outlet. Home Depot & Lowes have the brass adapters in the plumbing section. Watts #'s are LFA-116 & LFA-80. These two, along with the Dorman, will adapt the tester. Total cost ~$12.00 These parts will work on 1996 and older S/T series vehicles.

So I kind of have a more personal than mechanical question - kind of an "is this worth it anymore?" type of thing. If I'd payed the dealer the $1k, chances are I'd still be in this spot.

So lately, I'm spending my free time tearing this thing apart. And researching, learning and asking questions (and getting great advice) about what to do next. I'm finding myself spending $20 here, $50 here, $30 here - etc - on a daily basis, whether it be on tools, miscellaneous parts, oil treatment - the list just goes on and on.

I was really hoping the fix when I pulled the Plenum would be the end of it. And in a way it has been - it drives. It doesn't hesitate. It's a million times better than it was. But I've got a light flashing at me telling me I'm doing damage if I drive it. If that light wasn't there I wouldn't think twice about it, I just want to get from point a to b. The whole thing is starting to stress me out and drain me of time and money.

The fuel pressure is obviously an issue. You offer a great suggestion for narrowing it down. But I don't have an easy place to work on it. Basically cold, wet and on the pavement. I have a feeling that just getting access to the fuel filter outlet will be an hour of struggling trying to disconnect it with no room to work. But let's say I spend some time tomorrow on that...

I narrow it down to the pump or the regulator. So I figure it out, and now I'm looking at $40-$70 or so, plus dealing with pulling the plenum or dropping the gas tank - which for me is probably close to 4-5 hours of work or more.

I've got this whole blue smoke issue now. There's like a 99% chance that the cause of that is a valve/seal/gasket (or worse) right? I mean, best possible scenario this "Restore" stuff actually works - but how likely is that? That's probably a bigger issue than the fuel problem, right?

Maybe everything goes perfectly fine. I've got pressure. The oil stops leaking. At that point chances are I've got to change at least the plugs and wires - which for me isn't an easy task - and it's not cheap from the shop.

I payed $1,500 for it, and I've got a good 3 years of solid use out of her. But I'm severely lacking in time, money and resources. Maybe it's time to pass it along to someone who could put it to better use than me - see if I can get some money out of it and buy a beater to get from a to b while I save up for something better?

Or maybe she's still reliable enough to get me around (~20 miles a day) while I save up? There are no drive-ability issues like there were when this started. What's the worst that could happen? I blow the cat? I ruin the engine? For all I know I already have. Is there any chance the light is still flashing from the severe problems mentioned before?

Weather and time permitting, tomorrow I'll grab the parts you mentioned (thanks) along with a new fuel filter (I've never changed it). Run the test through the old filter, then replace, re-test to see if that could maybe be the problem. Either way, fix the fuel issue and go from there.

What's killing me - and I know you can't answer this - is what will it take to fix her, how much time and money, and is it worth it?

Everyone's help is sincerely appreciated. But I'm starting to think maybe it's time to put her out to pasture, or just get everything I can out of her and focus on working my way towards buying something more reliable in the mean-time.

I hope that doesn't come across the wrong way. I'm frustrated with the situation - it's ALWAYS something lately with this Blazer - I truly do appreciate all of the great advice here.

I'll post the numbers if I get the chance to run the test tomorrow.

Thanks again.

#18

Thanks for all of your help Captain. It is GREATLY appreciated.

So I kind of have a more personal than mechanical question - kind of an "is this worth it anymore?" type of thing. If I'd payed the dealer the $1k, chances are I'd still be in this spot.

So lately, I'm spending my free time tearing this thing apart. And researching, learning and asking questions (and getting great advice) about what to do next. I'm finding myself spending $20 here, $50 here, $30 here - etc - on a daily basis, whether it be on tools, miscellaneous parts, oil treatment - the list just goes on and on.

I was really hoping the fix when I pulled the Plenum would be the end of it. And in a way it has been - it drives. It doesn't hesitate. It's a million times better than it was. But I've got a light flashing at me telling me I'm doing damage if I drive it. If that light wasn't there I wouldn't think twice about it, I just want to get from point a to b. The whole thing is starting to stress me out and drain me of time and money.

The fuel pressure is obviously an issue. You offer a great suggestion for narrowing it down. But I don't have an easy place to work on it. Basically cold, wet and on the pavement. I have a feeling that just getting access to the fuel filter outlet will be an hour of struggling trying to disconnect it with no room to work. But let's say I spend some time tomorrow on that...

I narrow it down to the pump or the regulator. So I figure it out, and now I'm looking at $40-$70 or so, plus dealing with pulling the plenum or dropping the gas tank - which for me is probably close to 4-5 hours of work or more.

I've got this whole blue smoke issue now. There's like a 99% chance that the cause of that is a valve/seal/gasket (or worse) right? I mean, best possible scenario this "Restore" stuff actually works - but how likely is that? That's probably a bigger issue than the fuel problem, right?

Maybe everything goes perfectly fine. I've got pressure. The oil stops leaking. At that point chances are I've got to change at least the plugs and wires - which for me isn't an easy task - and it's not cheap from the shop.

I payed $1,500 for it, and I've got a good 3 years of solid use out of her. But I'm severely lacking in time, money and resources. Maybe it's time to pass it along to someone who could put it to better use than me - see if I can get some money out of it and buy a beater to get from a to b while I save up for something better?

Or maybe she's still reliable enough to get me around (~20 miles a day) while I save up? There are no drive-ability issues like there were when this started. What's the worst that could happen? I blow the cat? I ruin the engine? For all I know I already have. Is there any chance the light is still flashing from the severe problems mentioned before?

Weather and time permitting, tomorrow I'll grab the parts you mentioned (thanks) along with a new fuel filter (I've never changed it). Run the test through the old filter, then replace, re-test to see if that could maybe be the problem. Either way, fix the fuel issue and go from there.

What's killing me - and I know you can't answer this - is what will it take to fix her, how much time and money, and is it worth it?

Everyone's help is sincerely appreciated. But I'm starting to think maybe it's time to put her out to pasture, or just get everything I can out of her and focus on working my way towards buying something more reliable in the mean-time.

I hope that doesn't come across the wrong way. I'm frustrated with the situation - it's ALWAYS something lately with this Blazer - I truly do appreciate all of the great advice here.

I'll post the numbers if I get the chance to run the test tomorrow.

Thanks again.

So I kind of have a more personal than mechanical question - kind of an "is this worth it anymore?" type of thing. If I'd payed the dealer the $1k, chances are I'd still be in this spot.

So lately, I'm spending my free time tearing this thing apart. And researching, learning and asking questions (and getting great advice) about what to do next. I'm finding myself spending $20 here, $50 here, $30 here - etc - on a daily basis, whether it be on tools, miscellaneous parts, oil treatment - the list just goes on and on.

I was really hoping the fix when I pulled the Plenum would be the end of it. And in a way it has been - it drives. It doesn't hesitate. It's a million times better than it was. But I've got a light flashing at me telling me I'm doing damage if I drive it. If that light wasn't there I wouldn't think twice about it, I just want to get from point a to b. The whole thing is starting to stress me out and drain me of time and money.

The fuel pressure is obviously an issue. You offer a great suggestion for narrowing it down. But I don't have an easy place to work on it. Basically cold, wet and on the pavement. I have a feeling that just getting access to the fuel filter outlet will be an hour of struggling trying to disconnect it with no room to work. But let's say I spend some time tomorrow on that...

I narrow it down to the pump or the regulator. So I figure it out, and now I'm looking at $40-$70 or so, plus dealing with pulling the plenum or dropping the gas tank - which for me is probably close to 4-5 hours of work or more.

I've got this whole blue smoke issue now. There's like a 99% chance that the cause of that is a valve/seal/gasket (or worse) right? I mean, best possible scenario this "Restore" stuff actually works - but how likely is that? That's probably a bigger issue than the fuel problem, right?

Maybe everything goes perfectly fine. I've got pressure. The oil stops leaking. At that point chances are I've got to change at least the plugs and wires - which for me isn't an easy task - and it's not cheap from the shop.

I payed $1,500 for it, and I've got a good 3 years of solid use out of her. But I'm severely lacking in time, money and resources. Maybe it's time to pass it along to someone who could put it to better use than me - see if I can get some money out of it and buy a beater to get from a to b while I save up for something better?

Or maybe she's still reliable enough to get me around (~20 miles a day) while I save up? There are no drive-ability issues like there were when this started. What's the worst that could happen? I blow the cat? I ruin the engine? For all I know I already have. Is there any chance the light is still flashing from the severe problems mentioned before?

Weather and time permitting, tomorrow I'll grab the parts you mentioned (thanks) along with a new fuel filter (I've never changed it). Run the test through the old filter, then replace, re-test to see if that could maybe be the problem. Either way, fix the fuel issue and go from there.

What's killing me - and I know you can't answer this - is what will it take to fix her, how much time and money, and is it worth it?

Everyone's help is sincerely appreciated. But I'm starting to think maybe it's time to put her out to pasture, or just get everything I can out of her and focus on working my way towards buying something more reliable in the mean-time.

I hope that doesn't come across the wrong way. I'm frustrated with the situation - it's ALWAYS something lately with this Blazer - I truly do appreciate all of the great advice here.

I'll post the numbers if I get the chance to run the test tomorrow.

Thanks again.

But to be on a more realistic view of value wise. Yes it's worth fixing even if it's broke (unless a bad tranny/engine or something major). It's generally worth more if all the problems with it are solved.

A clogged cat can do bad things. It's restricting the engine from "breathing" which isn't good.

My question is, is your system fuel injected? I'd assume so cause you have a spider injector but I'm not up to date on your year, I'm good for 98+. But I'll repost a simple way to test what's causing the issue, ether your fuel rail or your pump. I'm going to copy and paste it from a thread I posted on earlier today so it'll be the same thing I told another guy.

Do the same test but pinch the feed and return line then turn the key off. This will isolate your fuel rail from the rest of the system. If your pressure is stays the same and no drop then check the vacuum line for leaks. If there is no leak then it's likely the check valve in the tank or something else in the tank.

Basically what this does is it forces the pressure to stay in the fuel rails so if there's a leak there it'll drop PSI. If there's no leak then it's from the tank.

This should help you isolate the problem better.

And check your main vacuum line, on mine it's in a very bad spot. Bad design, mines has to be near the throttle body where it will eventually melt in a few years. Amazing how a $3.00 hose will make things run poor. But on mine I lost my 4WD and low end torque. So this is something you'll want to check while you're under the hood. It may be causing issues. But I doubt it since you're running normal idle and all that.

If it is your Fuel Pump search on the forum here. AC Delco and Delphi are the most commonly suggested and they work the best on our blazers too. I believe a fuel pump will run you $120-150 online.

#19

...Do the same test but pinch the feed and return line then turn the key off. This will isolate your fuel rail from the rest of the system. If your pressure is stays the same and no drop then check the vacuum line for leaks. If there is no leak then it's likely the check valve in the tank or something else in the tank.

Basically what this does is it forces the pressure to stay in the fuel rails so if there's a leak there it'll drop PSI. If there's no leak then it's from the tank...

Basically what this does is it forces the pressure to stay in the fuel rails so if there's a leak there it'll drop PSI. If there's no leak then it's from the tank...

Last edited by Captain Hook; 02-17-2014 at 08:48 PM.

#20

The fuel return line should never be restricted while the pump is running. Checking fuel pressure at the fuel filter outlet, as described above, accomplishes four things: First and foremost is to avoid exposing the regulator diaphragm to pressures exceeding 75psi, (restricting the return line does exactly that). If/when that happens, the diaphragm will likely rupture. The back side of the diaphragm is exposed to manifold absolute pressure, so no vacuum line is required. #2 is to check the maximum output pressure of the pump. 1996 through 2005 spec is 73psi to 108psi. Even a borderline pump can destroy the regulator in a heartbeat. #3 is to isolate the pump from the system, not vice versa. The results determine if the leakdown, (if any) is in the tank, or in the plenum. #4 is to make sure the pump check valve can hold sufficient pressure. Fuel pressure must remain above 55psi for at least 10 minutes after the pump shuts off.

To make it clear cause I see where the confusion is. You do this after you turn the key to on engine off and the pump is done building pressure.

Again this will not cause harm because all you do is hold pressure in one part of the system and monitoring for a pressure drop.