Odd No-Start Condition (Hydro-locking?)

#1

I had a few issues with my '01 ZR2 and just tackled them all. Like everyone else, my OEM intake manifold gaskets were leaking so I switched them out for the nice Fel-Pro ones. I also put in a new Delphi fuel pump (the good pumps), a fuel pressure regulator, the new MPFI fuel injection spider and some other odds and ends.

When I got done the car ran like it was just made. I was very happy. After all this was done, I did an oil change and was doing a coolant flush so the car had been idling wonderfully for a few hours that day.

when I filled the radiator back up, I went to start the car and it turned over for 2 or 3 seconds and then BAM the motor IMMEDIATELY stopped turning over. This is sorta hard to explain because I have never seen a car do this but imagine this: you are cranking the car a few seconds (normally it would have already started by now) but it keeps turning over and then all of the sudden, its like someone poured cement in the cylinders and the pistons come to halt in .001 seconds. It's sort of violent and makes sort of a bang when this happens. Its literally like it gets hydro-locked at 2.5 seconds of cranking and instantly stops. VERY bad for the piston rod!!

It seemed like there was fluid in the cylinders. So I pulled all the spark plugs and the fuel pump relay. The motor turned over perfectly fine (as you'd expect). I noticed nothing coming out of cylinders when the plugs were out. Keeping the relay out, I put ONE spark plug back in at a time and the engine turned over without issue. I put in a 2nd and 3rd plug (til I got to 6) turning it over after each one. The engine turned over perfectly after each one.

So now I have all the plugs back in, the fuel pump relay is out, and the engine turns over just fine (obviously its not starting as I'm just testing if it'll come to screaming halt) NOW, I plug in the fuel pump relay and BAM, same thing. The engine turns over for a second or so and BANG! (loud noise)...it stops. I feel like I'm about to bend a rod (if I already haven't) so this is freaking me out.

If I take the relay out again, the engine will turn over as normal. It seems like its being hydro-locked or something when the fuel pump is allowed to go. Then I thought maybe I dont have spark and the fuel is just adding up (even though it shouldn't, cuz it should just come out the exhaust valve). Well, spark off the plugs is good and spark off the coil is good.

I am at a total loss. Has anyone ever seen this condition? Why would it run great for like 2 hours and then start doing this?

When I got done the car ran like it was just made. I was very happy. After all this was done, I did an oil change and was doing a coolant flush so the car had been idling wonderfully for a few hours that day.

when I filled the radiator back up, I went to start the car and it turned over for 2 or 3 seconds and then BAM the motor IMMEDIATELY stopped turning over. This is sorta hard to explain because I have never seen a car do this but imagine this: you are cranking the car a few seconds (normally it would have already started by now) but it keeps turning over and then all of the sudden, its like someone poured cement in the cylinders and the pistons come to halt in .001 seconds. It's sort of violent and makes sort of a bang when this happens. Its literally like it gets hydro-locked at 2.5 seconds of cranking and instantly stops. VERY bad for the piston rod!!

It seemed like there was fluid in the cylinders. So I pulled all the spark plugs and the fuel pump relay. The motor turned over perfectly fine (as you'd expect). I noticed nothing coming out of cylinders when the plugs were out. Keeping the relay out, I put ONE spark plug back in at a time and the engine turned over without issue. I put in a 2nd and 3rd plug (til I got to 6) turning it over after each one. The engine turned over perfectly after each one.

So now I have all the plugs back in, the fuel pump relay is out, and the engine turns over just fine (obviously its not starting as I'm just testing if it'll come to screaming halt) NOW, I plug in the fuel pump relay and BAM, same thing. The engine turns over for a second or so and BANG! (loud noise)...it stops. I feel like I'm about to bend a rod (if I already haven't) so this is freaking me out.

If I take the relay out again, the engine will turn over as normal. It seems like its being hydro-locked or something when the fuel pump is allowed to go. Then I thought maybe I dont have spark and the fuel is just adding up (even though it shouldn't, cuz it should just come out the exhaust valve). Well, spark off the plugs is good and spark off the coil is good.

I am at a total loss. Has anyone ever seen this condition? Why would it run great for like 2 hours and then start doing this?

#2

UNBELIEVABLE, this car must be haunted. It seems to make sense that the timing is off by it's symptoms but I KNOW I did the timing correct just as the service manual says to do. After all, the car was running flawlessly. So I go out, take off spark plug #1 and stuff a damp rag in its hole. I bump the key till it loudly pops out of the hole. I look down at the crank shaft marks and they are almost perfectly lined up (as always when I do it like this.) So I move the marks a degree or two so they are dead-on. Now I go and undo the distributor cap expecting to see the rotor NOT pointing at the "6" mark because it seems like my timing is off. BUT I FIND THAT IT IS! It's perfect - my timing was not off. I pulled the distributor out and everything looks fine. I dropped it back in just like it was with the rotor pointing at the "6" mark and buttoned it all back up thinking "well, I didnt do anything so I dont know why it should start now". I turn the key and it started up like a brand new car!!!!!!!!!!!!!

I let it run for 5 minutes and then turned it off. A few minutes later I cranked it and it started perfectly a second time. Again, I let it run for 5 minutes and turned it off. ON THE THIRD START, IT DID THE EXACT SAME THING AGAIN AS BEFORE...No start and motor banging to a halt like the timing is off again when I know damn well it's not.

What is going on??? I can't trust this car to drive it because I have no idea when its going to decide to have "out of timing" symptoms when it actually has proper timing and leave me stranded. This car has been 110% reliable its entire life and it only has 76K on it. Please someone throw some ideas at me cuz I cant drive this thing like this. I basically have no wheels now until I figure this out. One drive to the store is going to equal a call to a tow truck.

I let it run for 5 minutes and then turned it off. A few minutes later I cranked it and it started perfectly a second time. Again, I let it run for 5 minutes and turned it off. ON THE THIRD START, IT DID THE EXACT SAME THING AGAIN AS BEFORE...No start and motor banging to a halt like the timing is off again when I know damn well it's not.

What is going on??? I can't trust this car to drive it because I have no idea when its going to decide to have "out of timing" symptoms when it actually has proper timing and leave me stranded. This car has been 110% reliable its entire life and it only has 76K on it. Please someone throw some ideas at me cuz I cant drive this thing like this. I basically have no wheels now until I figure this out. One drive to the store is going to equal a call to a tow truck.

#3

When the engine is running: if the timing was off, or the distributor was not installed correctly, P1345 would set and the SES light would come on. What you describe are classic symptoms of crossfire inside the distributor cap. Install an AC Delco distributor cap & rotor, (yes, it does make a difference). Put a dab of silicone dielectric grease on each terminal, inside and out, of the cap. Then check/adjust camshaft retard. Must be zero degrees, + or - 2 degrees. It is adjusted by rotating the distributor while monitoring camshaft retard streaming data on a capable scan tool.

Edit:

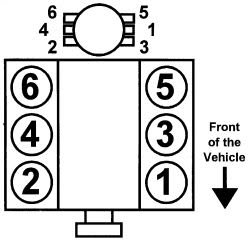

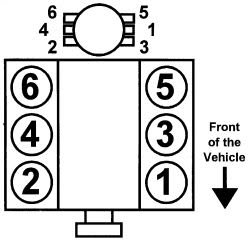

Make sure the cap is wired properly:

Edit:

Make sure the cap is wired properly:

Last edited by Captain Hook; 02-02-2013 at 08:50 AM.

#4

Okay, here's an update from the previous post where it started and ran twice, ran great, and then wouldn't start the third time.

I go out this afternoon and didn't touch a thing. I wanted to attempt to start it to see what it would do. IT STARTED INSTANTLY! I was shocked, but pleased to say the least. So, after redoing the timing from last night (the timing was found to be good though), it started twice and then wouldnt start the third time. I make NO changes and it starts first thing today?!?! I am seriously thinking something got wet from when I was doing the radiator flush. I admit, water was going all over everything. With that said, when I opened the distributor to recheck the timing last night, it was NOT wet at all. So, I'm wondering what kind of electrical connection getting wet would cause this no start condition?

So, today I continue finishing the radiator flush (yes, I covered up the motor this time with a trash bag). The car idled for a total of like 2 hours today PERFECTLY. It was restarted throughout the day at least 10 times PERFECTLY. The no-start condition did not show up today. The engine is running extremely smoothly. With that said, near the end of the day when I was going to turn it off, I noticed the Check Engine Light on. I checked throughout the whole day for a Check Engine Light but it never came on, except right at the end. I ran the code and it was:

P0300 Random/Multiple Cylinder Misfire.

Again, the car runs beautifully. So, is it possible this code is showing up due to all the times I was previously trying to start it when it was doing it's no-start condition? The car literally runs like it was just made. I know my car very well, if it was misfiring now, would I know? Would it be obvious?

I go out this afternoon and didn't touch a thing. I wanted to attempt to start it to see what it would do. IT STARTED INSTANTLY! I was shocked, but pleased to say the least. So, after redoing the timing from last night (the timing was found to be good though), it started twice and then wouldnt start the third time. I make NO changes and it starts first thing today?!?! I am seriously thinking something got wet from when I was doing the radiator flush. I admit, water was going all over everything. With that said, when I opened the distributor to recheck the timing last night, it was NOT wet at all. So, I'm wondering what kind of electrical connection getting wet would cause this no start condition?

So, today I continue finishing the radiator flush (yes, I covered up the motor this time with a trash bag). The car idled for a total of like 2 hours today PERFECTLY. It was restarted throughout the day at least 10 times PERFECTLY. The no-start condition did not show up today. The engine is running extremely smoothly. With that said, near the end of the day when I was going to turn it off, I noticed the Check Engine Light on. I checked throughout the whole day for a Check Engine Light but it never came on, except right at the end. I ran the code and it was:

P0300 Random/Multiple Cylinder Misfire.

Again, the car runs beautifully. So, is it possible this code is showing up due to all the times I was previously trying to start it when it was doing it's no-start condition? The car literally runs like it was just made. I know my car very well, if it was misfiring now, would I know? Would it be obvious?

#5

I know your car very well too, perhaps better than you think  As mentioned in post #3, "What you describe are classic symptoms of crossfire inside the distributor cap. Install an AC Delco distributor cap & rotor, (yes, it does make a difference). Put a dab of silicone dielectric grease on each terminal, inside and out, of the cap. Then check/adjust camshaft retard. Must be zero degrees, + or - 2 degrees."

As mentioned in post #3, "What you describe are classic symptoms of crossfire inside the distributor cap. Install an AC Delco distributor cap & rotor, (yes, it does make a difference). Put a dab of silicone dielectric grease on each terminal, inside and out, of the cap. Then check/adjust camshaft retard. Must be zero degrees, + or - 2 degrees."

As mentioned in post #3, "What you describe are classic symptoms of crossfire inside the distributor cap. Install an AC Delco distributor cap & rotor, (yes, it does make a difference). Put a dab of silicone dielectric grease on each terminal, inside and out, of the cap. Then check/adjust camshaft retard. Must be zero degrees, + or - 2 degrees."

As mentioned in post #3, "What you describe are classic symptoms of crossfire inside the distributor cap. Install an AC Delco distributor cap & rotor, (yes, it does make a difference). Put a dab of silicone dielectric grease on each terminal, inside and out, of the cap. Then check/adjust camshaft retard. Must be zero degrees, + or - 2 degrees."

#6

I know your car very well too, perhaps better than you think  As mentioned in post #3, "What you describe are classic symptoms of crossfire inside the distributor cap. Install an AC Delco distributor cap & rotor, (yes, it does make a difference). Put a dab of silicone dielectric grease on each terminal, inside and out, of the cap. Then check/adjust camshaft retard. Must be zero degrees, + or - 2 degrees."

As mentioned in post #3, "What you describe are classic symptoms of crossfire inside the distributor cap. Install an AC Delco distributor cap & rotor, (yes, it does make a difference). Put a dab of silicone dielectric grease on each terminal, inside and out, of the cap. Then check/adjust camshaft retard. Must be zero degrees, + or - 2 degrees."

As mentioned in post #3, "What you describe are classic symptoms of crossfire inside the distributor cap. Install an AC Delco distributor cap & rotor, (yes, it does make a difference). Put a dab of silicone dielectric grease on each terminal, inside and out, of the cap. Then check/adjust camshaft retard. Must be zero degrees, + or - 2 degrees."

As mentioned in post #3, "What you describe are classic symptoms of crossfire inside the distributor cap. Install an AC Delco distributor cap & rotor, (yes, it does make a difference). Put a dab of silicone dielectric grease on each terminal, inside and out, of the cap. Then check/adjust camshaft retard. Must be zero degrees, + or - 2 degrees."I don't think most people have a scan tool that would do this. I know I don't. If I did, I'd just go ahead and do it. I specifically asked a mechanic about this. I said "I heard you have to rotate the distributor when doing the camshaft retard process." He said something to the effect of: "no, you just tweak it on the scan tool and the car learns itself by revving up and down"

Can someone explain in a little detail the camshaft retard process.

- What is it?

- Why is it necessary?

- If you don't do it after putting in the distributor but the car runs perfect, is it mandatory that you have to do it?

- Will it damage something if you don't?

- Is there a cheap scan tool that people can get? If so, please recommend.

Thanks!

#7

Not sure who you asked, but I would question their knowledge when it comes to working on vehicles  Camshaft retard is not "tweaked" on a scan tool; you view it on a scan tool. It is a physical adjustment that a "technician" makes, not a mechanic.

Camshaft retard is not "tweaked" on a scan tool; you view it on a scan tool. It is a physical adjustment that a "technician" makes, not a mechanic.

The PCM uses data from the camshaft position sensor, along with the crankshaft position sensor, to detect and accurately identify cylinder misfire. When adjusting camshaft retard, the rotor segment is also aligned with the terminals inside the cap. This keeps crossfire inside the cap to a bare minimum when the PCM commands the ignition module to fire the ignition coil.

Camshaft retard adjustment aligns the camshaft position sensor with the camshaft, (hence the name). It is adjusted by slightly rotating the distributor while watching camshaft retard streaming data on a capable scan tool, (the el cheapo $500 jobbies can't access it). There is a hole in the lower intake manifold that the distributor goes through. The inside diameter is slightly larger than the outside diameter of the distributor. The "slop", along with the design of the hold down bracket, will only allow the distributor to be rotated ~7 degrees in each direction.

If the camshaft position sensor is defective or unplugged, a DTC will be set in memory, but the engine will still start and run. If/when the distributor hold down is loosened, (or the distributor is removed), camshaft retard should be checked, and adjusted if necessary. Desired spec is zero degrees with a tolerance of +or- 2 degrees. If you remove the distributor, the odds are greatly against you of installing it correctly. If it is out of spec, crossfire will occur. The farther off it is, the more crossfire. If it's off more than ~27 degrees, DTC P1345 will set in memory and the SES light will come on.

If it's out of spec:

The PCM may or may not set a P0300 series DTC.

You may or may not notice a misfire.

It will affect engine performance, fuel mileage, and distributor cap longevity.

Cylinder misfire might not be accurately identified, or detected at all.

Auto enginuity makes a software program, (at a decent price) for PC's & laptops that will access camshaft retard streaming data. If you're looking for a scan tool that is capable, be prepared to spend upwards of $1500, for a decent used one.

Camshaft retard is not "tweaked" on a scan tool; you view it on a scan tool. It is a physical adjustment that a "technician" makes, not a mechanic.

Camshaft retard is not "tweaked" on a scan tool; you view it on a scan tool. It is a physical adjustment that a "technician" makes, not a mechanic.The PCM uses data from the camshaft position sensor, along with the crankshaft position sensor, to detect and accurately identify cylinder misfire. When adjusting camshaft retard, the rotor segment is also aligned with the terminals inside the cap. This keeps crossfire inside the cap to a bare minimum when the PCM commands the ignition module to fire the ignition coil.

Camshaft retard adjustment aligns the camshaft position sensor with the camshaft, (hence the name). It is adjusted by slightly rotating the distributor while watching camshaft retard streaming data on a capable scan tool, (the el cheapo $500 jobbies can't access it). There is a hole in the lower intake manifold that the distributor goes through. The inside diameter is slightly larger than the outside diameter of the distributor. The "slop", along with the design of the hold down bracket, will only allow the distributor to be rotated ~7 degrees in each direction.

If the camshaft position sensor is defective or unplugged, a DTC will be set in memory, but the engine will still start and run. If/when the distributor hold down is loosened, (or the distributor is removed), camshaft retard should be checked, and adjusted if necessary. Desired spec is zero degrees with a tolerance of +or- 2 degrees. If you remove the distributor, the odds are greatly against you of installing it correctly. If it is out of spec, crossfire will occur. The farther off it is, the more crossfire. If it's off more than ~27 degrees, DTC P1345 will set in memory and the SES light will come on.

If it's out of spec:

The PCM may or may not set a P0300 series DTC.

You may or may not notice a misfire.

It will affect engine performance, fuel mileage, and distributor cap longevity.

Cylinder misfire might not be accurately identified, or detected at all.

Auto enginuity makes a software program, (at a decent price) for PC's & laptops that will access camshaft retard streaming data. If you're looking for a scan tool that is capable, be prepared to spend upwards of $1500, for a decent used one.

#8

@Captain Hook...THANK YOU for that explanation. That's pretty much what I figured but I didn't want to assume. Having someone experienced spell it out makes things much easier for me leaving me with no questions.

As for the mechanic guy, I'll try to reiterate what he said in my own words: He said that you basically hook up the scan tool, run the cam retard procedure on the scan tool and it will have the vehicle idle and rev up and down, etc and basically learn where it's at and adjust accordingly. I think he means that if the scan tool finds that its +3 degrees off, it'll electronically time the car's computer accordingly to adjust and therefore no physical adjustment is necessary. I can see this be the case on some fancy Mercedes/BMW thats all computerized, but not an '01 V6 Vortec.

Now, I am going to go down there probably tomorrow and nonchalantly ask him again how the cam retard process is in more detail. After his reply, if he doesn't mention physically rotating the distributor, then I'm going to ask him about that. I literally do 99% of ALL my own car work. After all, I just did the intake manifold gaskets, MPFI fuel injector upgrade, fuel pump replacement, etc which was a lot of work. My mentality is: if I can do it myself, I'm not going to pay out the butt for someone else to do it when they'll undoubtedly do it sloppier than I would cuz it's not their car. But, this guy is literally 100's of feet down the street from me and I need to know if I can trust him or not should I ever actually need a mechanic in the future.

I ran a BUNCH of errands today, maybe 60 miles of driving and a dozen starts throughout the day and the car was PERFECT.

I have one last issue with this car that I thought would be resolved when I replaced the fuel pump canister thing. I was going to create a thread about it but I'll ask here first cuz you are obviously familiar with these cars.

I have had problems with the gas gauge for a long time. When I did a little research, I found out that a TON of people have gas gauges that act up in their S10s. However, my problem is not like what everyone else explains. Everyone elses sort of "floats" back and forth (like a VU meter on an old school amp where the needle goes up and down with the beat of the music)

I only saw one guy out of many, many threads all over the net who explained his problem that matched mine. My gauge works perfectly from full all the way down to a 1/4 of a tank. Once you hit a 1/4 funny things start happening. You know you're at a 1/4 yet all of the sudden, the gauge will just fall to empty and many times the low fuel light will come on. BUT, here's where it gets weird: if you put the transmission from D to N, the needle goes right back up to where it's supposed to. The 'putting it in N trick' works while going 70 MPH down the highway or idling in a parking lot. If you keep driving and the fuel slowly goes lower so now you're at 1/8 of a tank and the same thing can happen. It'll fall to empty and then you put it in N and it'll go back up to 1/8.

This 'falling' that the needle does when you are at or below a 1/4 of a tank happens randomly as you drive, but only when you are at 1/4 or lower. What gets me is why the hell does putting it in N force the gauge to actually read the correct ohms on the rheostat of the fuel sender??? How weird is that?

The factory sender was just replaced with a very expensive premium Delphi fuel pump assembly. This new assembly obviously has a new rheostat and the tiny connectors that rub against the resistance strip are the new, upgraded gold ones. I thought with the new unit, my gauge issue would be fixed but it's doing it on BOTH fuel senders so its not that.

Is the actual gauge bad in the cluster? If so, can you replace JUST the gauge in the cluster or do you have to change out the whole cluster? I really want to like Chevy's (cuz I've owned LOTS of them) but man, they sure could be built better.

As for the mechanic guy, I'll try to reiterate what he said in my own words: He said that you basically hook up the scan tool, run the cam retard procedure on the scan tool and it will have the vehicle idle and rev up and down, etc and basically learn where it's at and adjust accordingly. I think he means that if the scan tool finds that its +3 degrees off, it'll electronically time the car's computer accordingly to adjust and therefore no physical adjustment is necessary. I can see this be the case on some fancy Mercedes/BMW thats all computerized, but not an '01 V6 Vortec.

Now, I am going to go down there probably tomorrow and nonchalantly ask him again how the cam retard process is in more detail. After his reply, if he doesn't mention physically rotating the distributor, then I'm going to ask him about that. I literally do 99% of ALL my own car work. After all, I just did the intake manifold gaskets, MPFI fuel injector upgrade, fuel pump replacement, etc which was a lot of work. My mentality is: if I can do it myself, I'm not going to pay out the butt for someone else to do it when they'll undoubtedly do it sloppier than I would cuz it's not their car. But, this guy is literally 100's of feet down the street from me and I need to know if I can trust him or not should I ever actually need a mechanic in the future.

I ran a BUNCH of errands today, maybe 60 miles of driving and a dozen starts throughout the day and the car was PERFECT.

I have one last issue with this car that I thought would be resolved when I replaced the fuel pump canister thing. I was going to create a thread about it but I'll ask here first cuz you are obviously familiar with these cars.

I have had problems with the gas gauge for a long time. When I did a little research, I found out that a TON of people have gas gauges that act up in their S10s. However, my problem is not like what everyone else explains. Everyone elses sort of "floats" back and forth (like a VU meter on an old school amp where the needle goes up and down with the beat of the music)

I only saw one guy out of many, many threads all over the net who explained his problem that matched mine. My gauge works perfectly from full all the way down to a 1/4 of a tank. Once you hit a 1/4 funny things start happening. You know you're at a 1/4 yet all of the sudden, the gauge will just fall to empty and many times the low fuel light will come on. BUT, here's where it gets weird: if you put the transmission from D to N, the needle goes right back up to where it's supposed to. The 'putting it in N trick' works while going 70 MPH down the highway or idling in a parking lot. If you keep driving and the fuel slowly goes lower so now you're at 1/8 of a tank and the same thing can happen. It'll fall to empty and then you put it in N and it'll go back up to 1/8.

This 'falling' that the needle does when you are at or below a 1/4 of a tank happens randomly as you drive, but only when you are at 1/4 or lower. What gets me is why the hell does putting it in N force the gauge to actually read the correct ohms on the rheostat of the fuel sender??? How weird is that?

The factory sender was just replaced with a very expensive premium Delphi fuel pump assembly. This new assembly obviously has a new rheostat and the tiny connectors that rub against the resistance strip are the new, upgraded gold ones. I thought with the new unit, my gauge issue would be fixed but it's doing it on BOTH fuel senders so its not that.

Is the actual gauge bad in the cluster? If so, can you replace JUST the gauge in the cluster or do you have to change out the whole cluster? I really want to like Chevy's (cuz I've owned LOTS of them) but man, they sure could be built better.

#9

On your 2001: At the fuel pump module there are 4 wires, the two black ones are grounds for the fuel level sender and the fuel pump. The level sender actually grounds in the front of the vehicle, lots of places in-between to mess up. It operates on 5VDC and is very sensitive to changes in resistance along the way. When replacing the pump module, I splice both blacks together close to the module connector and solder on a 10 gauge wire and run it to a good clean body ground. The signal wire for the level sender goes up to the BCM, (Body Control Module) which is under the dash. The onboard computers are interfaced and the BCM ultimately sends the signal to the cluster logic module, and then to the gauge via a printed circuit board. The high end scan tools will allow you to access the BCM and command darn near everything on the vehicle right from the scan tool. One of the things is fuel level. You can command a certain percentage of fuel level that you want the BCM to send to the dash gauge, to make sure the BCM can provide proper data, and the gauge displays it. If adding the ground doesn't help, you'll need to get into the BCM and diagnose the problem.

Edit: Normally the level sender causes the screwy gauge, but not likely on yours due to the shifting affecting it.

Edit: Normally the level sender causes the screwy gauge, but not likely on yours due to the shifting affecting it.

Last edited by Captain Hook; 02-04-2013 at 09:55 PM.

#10

Darn it, I just had the whole tank dropped and was soldering those wires because the new Delphi pump comes with that newer, more robust connector assembly. I could have done all this while I had it down..lol. shux.

Question 1: So, you're saying, I can undo the shrink tubing on the small and large black wires where the new fuel pump connector splices in, solder them together and then solder a 10 AWG at the same time and maybe ground it where that ground strap from the fuel filler pipe goes (cuz its right there on the rear frame) Connecting the small fuel sender ground and the fuel pump ground together wont be an issue, right? (I only ask cuz sometimes you have weird things like fuel injectors that are ground pulsed where you couldn't do that.)

I'll have to wait till the tank is really low if I drop it again but I just filled up today.

Question 2: One last question about the cam retard. When adjusting it, is it done by rotating the distributor clock wise or counter-clockwise, or, is it done by sliding the distributor BACK and FORTH (meaning closer or farther away) from the bolt that holds down the clamp? The reason I ask is because the "play" in the clamp is specifically slotted to give play to and from the hold down bolt; the slot in the clamp doesn't really provide play in a circular rotational way. I hope that makes sense.

Question 3: Have you seen these products? Check out this link I found: http://www.obdtruck.com/category.php?id_category=20 Look specifically at the last two products on that page. They say they can do "Timing Advance". Is that the same as cam retard? Would this do what I need?

Thanks!

Question 1: So, you're saying, I can undo the shrink tubing on the small and large black wires where the new fuel pump connector splices in, solder them together and then solder a 10 AWG at the same time and maybe ground it where that ground strap from the fuel filler pipe goes (cuz its right there on the rear frame) Connecting the small fuel sender ground and the fuel pump ground together wont be an issue, right? (I only ask cuz sometimes you have weird things like fuel injectors that are ground pulsed where you couldn't do that.)

I'll have to wait till the tank is really low if I drop it again but I just filled up today.

Question 2: One last question about the cam retard. When adjusting it, is it done by rotating the distributor clock wise or counter-clockwise, or, is it done by sliding the distributor BACK and FORTH (meaning closer or farther away) from the bolt that holds down the clamp? The reason I ask is because the "play" in the clamp is specifically slotted to give play to and from the hold down bolt; the slot in the clamp doesn't really provide play in a circular rotational way. I hope that makes sense.

Question 3: Have you seen these products? Check out this link I found: http://www.obdtruck.com/category.php?id_category=20 Look specifically at the last two products on that page. They say they can do "Timing Advance". Is that the same as cam retard? Would this do what I need?

Thanks!

Last edited by calee4nyaboy; 02-05-2013 at 03:26 AM.