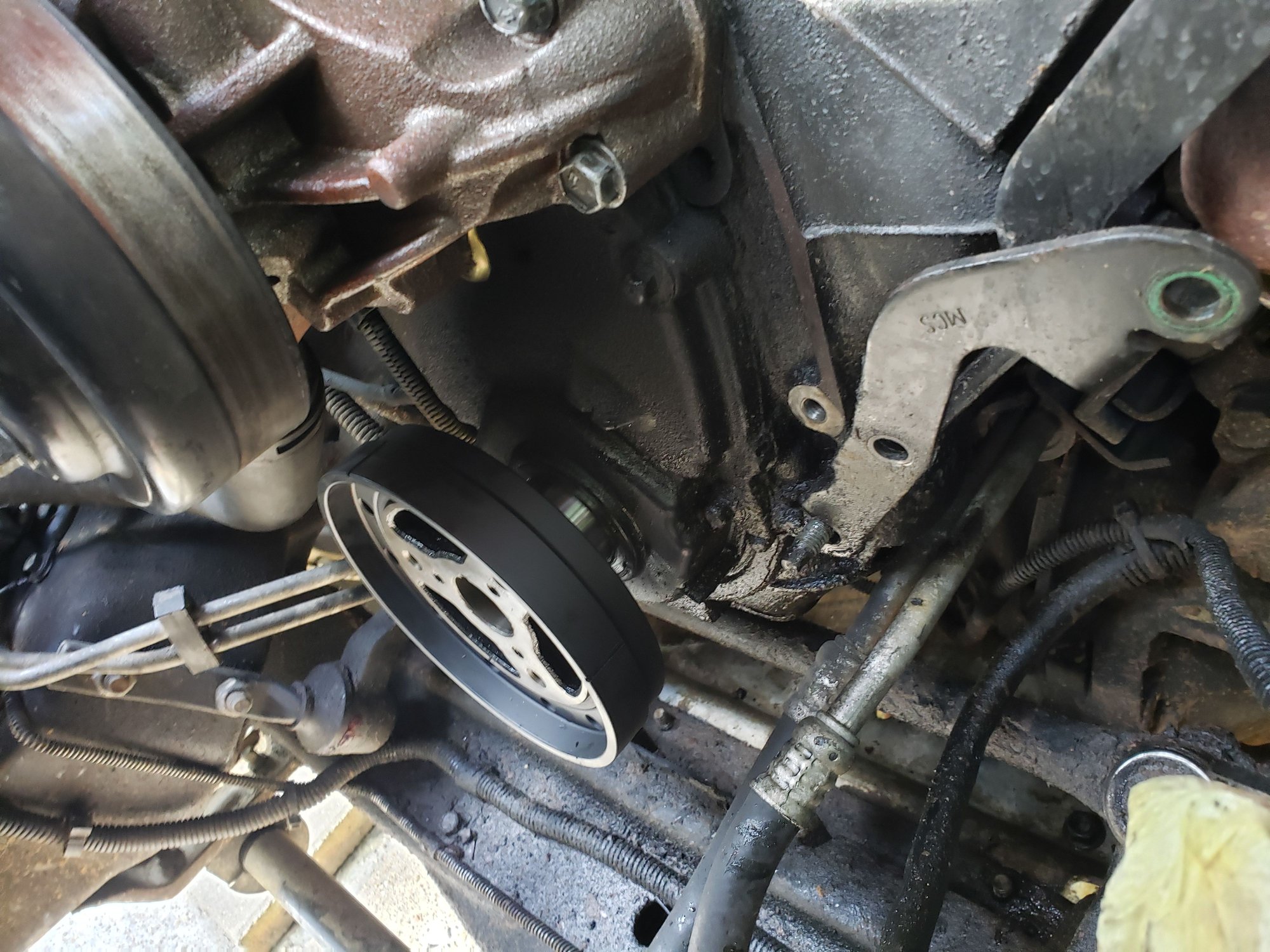

Stripped Crankshaft

#1

I've got a 1996 Chevy blazer with the 4.3 and my crankshaft seal was leaking so I removed the pulley and harmonic balancer and replaced the seal but when trying to reinstall the crankshaft the installer I used wasn't threaded all the way in even though I thought it was and it ripped a thread outta the crankshaft. I'm not sure what to do at this point. Any ideas?

#2

Clean up the threads with a thread chaser (go buy one - they are much cheaper than a crankshaft) Then go buy a Dorman balancer - these pretty much slip right onto the crank snout without the excessive force needed to pull the stock one on. Install your bolt if you still have enough threads (and you probably do). If not, get a slightly longer (Grade 8) bolt that will use threads further back in the crank (but not bottom out). Good luck and best wishes.

#3

Clean up the threads with a thread chaser (go buy one - they are much cheaper than a crankshaft) Then go buy a Dorman balancer - these pretty much slip right onto the crank snout without the excessive force needed to pull the stock one on. Install your bolt if you still have enough threads (and you probably do). If not, get a slightly longer (Grade 8) bolt that will use threads further back in the crank (but not bottom out). Good luck and best wishes.

#6

The installer stripped off when installing it so I still need to find some way to rethread or fix the first two threads to get a bolt to screw in

#7

If I do get you right: it ripped the first two threads off the installer tool and those remains are now stuck in the threads of the crankshaft snout?

If this is the case, I would use a pick or adequate tool to pry the remains from the crankshafts thread.

I have once modified an old allen key and ground it down to a kind of screwdriver blade. Together with a screwdriver we were able at that time to pick piece by piece of a stripped bolt from a thread.

In your case I would kind of make a miniature thread cutting steel similar to those found on a lathe. Use a bit of copper or aluminium sheet-metal or hose (i.e. hose from plumbing) to be able to leverage against the other side of the thread without damaging it. To properly work you may need an old screwdriver to limit the movement of the key.

https://www.carbideanddiamondtooling...8.10.14.16.TPI

something like this. If you can heat the allen key, you may bend the "handle" part 90 degrees to get kind of a "Z" form to have leverage. Or weld a piece of steel across the end of the key to form a "T" with which to leverage.

Or simply a vise-grip

https://www.canadiantire.ca/en/pdp/v...-0588686p.html

Good luck - and stick a piece of cardboard down the radiator if you have the shroud off.

If this is the case, I would use a pick or adequate tool to pry the remains from the crankshafts thread.

I have once modified an old allen key and ground it down to a kind of screwdriver blade. Together with a screwdriver we were able at that time to pick piece by piece of a stripped bolt from a thread.

In your case I would kind of make a miniature thread cutting steel similar to those found on a lathe. Use a bit of copper or aluminium sheet-metal or hose (i.e. hose from plumbing) to be able to leverage against the other side of the thread without damaging it. To properly work you may need an old screwdriver to limit the movement of the key.

https://www.carbideanddiamondtooling...8.10.14.16.TPI

something like this. If you can heat the allen key, you may bend the "handle" part 90 degrees to get kind of a "Z" form to have leverage. Or weld a piece of steel across the end of the key to form a "T" with which to leverage.

Or simply a vise-grip

https://www.canadiantire.ca/en/pdp/v...-0588686p.html

Good luck - and stick a piece of cardboard down the radiator if you have the shroud off.

#8

Yes, you will need to remove any damaged threads that have been transferred from the tool to the hole in the crankshaft. However, I think it is much more likely to have threads from the crank left on the tool because of its hardness. You can inspect better once you have the balancer off.

But you will definitely need to chase the threads before trying to screw in the bolt or a balance install tool. A thread chaser is better than a tap. Make sure to blow/wash out all the metal chips when you are done.

I am betting you will not need an install tool if you get the Dorman balancer. My original was so tight I could barely get it seated and it ended up wobbling just enough to make a belt chirp at idle. The belt chirp drove me bonkers. Replaced belts, pulleys, tensioners, etc. Finally bought the balancer. The Dorman I bought slid right on without a installer.

One work of caution. Don't beat a balancer on with a BFH. That ruins the thrust bearing on the crankshaft. You can however tap a little or use the install tool once the threads are straightened up.

Again, don't let your friend help.

Good luck!

Last edited by LesMyer; 07-17-2020 at 08:51 AM.

#9

We are talking about using the puller (not installer) to get the old balancer back off. Puller tool does not require threading into the bolt hole. But it does require something to block the hole in the crank for the tool to push on. Use a bolt that is one size smaller (without the washer) - one that will simply push into the hole. Then the tool will push on the head of the bolt.

Yes, you will need to remove any damaged threads that have been transferred from the tool to the hole in the crankshaft. However, I think it is much more likely to have threads from the crank left on the tool because of its hardness. You can inspect better once you have the balancer off.

But you will definitely need to chase the threads before trying to screw in the bolt or a balance install tool. A thread chaser is better than a tap. Make sure to blow/wash out all the metal chips when you are done.

I am betting you will not need an install tool if you get the Dorman balancer. My original was so tight I could barely get it seated and it ended up wobbling just enough to make a belt chirp at idle. The belt chirp drove me bonkers. Replaced belts, pulleys, tensioners, etc. Finally bought the balancer. The Dorman I bought slid right on without a installer.

One work of caution. Don't beat a balancer on with a BFH. That ruins the thrust bearing on the crankshaft. You can however tap a little or use the install tool once the threads are straightened up.

Again, don't let your friend help.

Good luck!

Yes, you will need to remove any damaged threads that have been transferred from the tool to the hole in the crankshaft. However, I think it is much more likely to have threads from the crank left on the tool because of its hardness. You can inspect better once you have the balancer off.

But you will definitely need to chase the threads before trying to screw in the bolt or a balance install tool. A thread chaser is better than a tap. Make sure to blow/wash out all the metal chips when you are done.

I am betting you will not need an install tool if you get the Dorman balancer. My original was so tight I could barely get it seated and it ended up wobbling just enough to make a belt chirp at idle. The belt chirp drove me bonkers. Replaced belts, pulleys, tensioners, etc. Finally bought the balancer. The Dorman I bought slid right on without a installer.

One work of caution. Don't beat a balancer on with a BFH. That ruins the thrust bearing on the crankshaft. You can however tap a little or use the install tool once the threads are straightened up.

Again, don't let your friend help.

Good luck!

#10

No RTV used. Mine isn't leaking, but a little tiny bit of RTV isn't going to hurt anything if done correctly. A lot of RTV inside your engine can slough off and end up going through your oiling system. If you put RTV on, put just a little thin smear in the balancer groove for the crank key and the part of the balancer that mates with the crank snout (not on the crank key or crankshaft itself). That way all RTV gets pushed to the outside of the engine when the balancer goes on. First spray down good with carb cleaner and dry good or RTV won't stick.

Last edited by LesMyer; 07-17-2020 at 01:18 PM.