2005 Jimmy Rear Bearings

#21

Now the problem. I can't find the c clips (presumably the shaft lock in the diagram)! Can anyone tell me exactly where they are and how to get at them? I read somewhere that the vehicle should be in neutral and I have mine in park - would that make any difference? I push in and pull out on the shaft hub but can't see the clips to remove them! Do I look through the pinion shaft space? That faces straight back and is hard to look inside!

Also, I was poking around for the filler plug around the top of the differential housing, as I will need that later, and can't find it either on the driver's side or the passenger's side or on top! So I need to find that and once I find it when I go to fill the differential with lubricant how do I pour that in? Is it necessary to set up a hose going into the plug and coming out the side of the vehicle to fill the differential to the top (like I've seen somewhere on the net)?

thanks,

quickcurrent

Also, I was poking around for the filler plug around the top of the differential housing, as I will need that later, and can't find it either on the driver's side or the passenger's side or on top! So I need to find that and once I find it when I go to fill the differential with lubricant how do I pour that in? Is it necessary to set up a hose going into the plug and coming out the side of the vehicle to fill the differential to the top (like I've seen somewhere on the net)?

thanks,

quickcurrent

If you have the pinion shaft out, you should be able to slide the axles from the outside in to get to the c-clips.

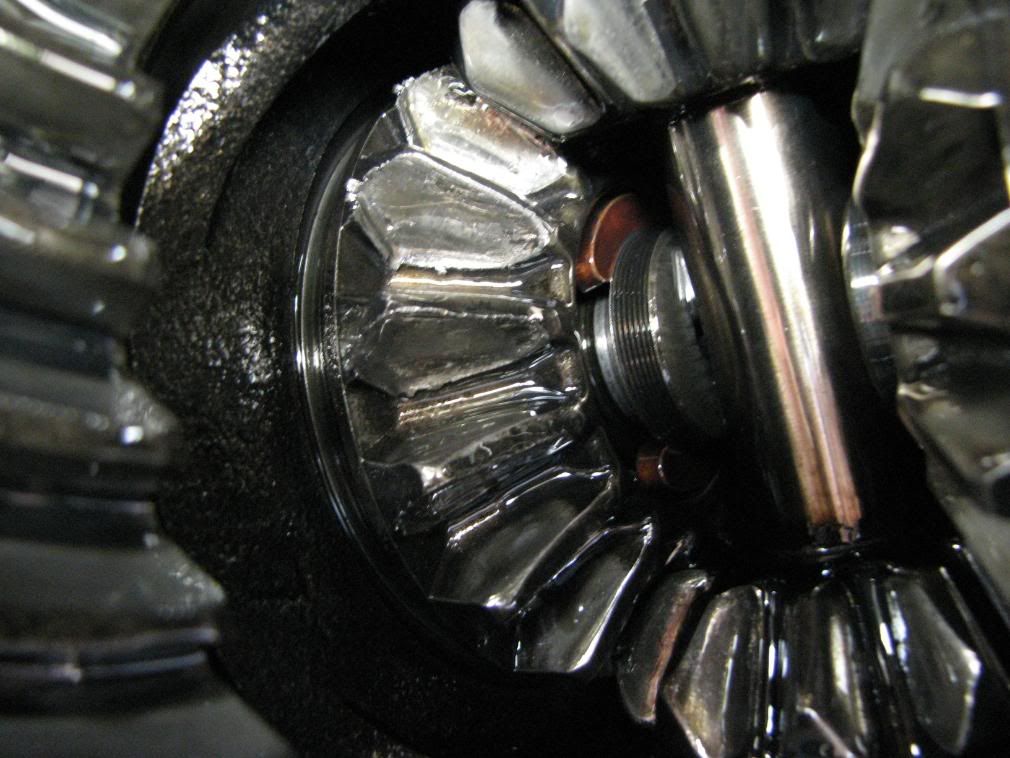

You can see where the c-clips rest in this picture. Right above the splines where the indent is before the end of the axle shaft:

And here is Kyle's pic of the fill plug from his Rear Axle Service thread:

#22

Thanks TripleBlackBlazer. Mine looks somewhat different, but I am not sure what the clips are on yours. Is it the bronze colored part?

The plug I can see. I was thinking that it was like an oil plug but it's the recessed head type. looks like I'll have to be very careful not to allow any dirt/rust to get in as I take it off. Hard to do when it has to be removed blindly or with a mirror!

quickcurrent

The plug I can see. I was thinking that it was like an oil plug but it's the recessed head type. looks like I'll have to be very careful not to allow any dirt/rust to get in as I take it off. Hard to do when it has to be removed blindly or with a mirror!

quickcurrent

#23

What I see when looking at the differential is something like this https://w05.dealerconnect.chrysler.c...S/80011558.gif but the c-clip is illusive. Is it inside the space that the pinion shaft was in? Would placing the vehicle in neutral allow that mechanism to rotate to let me see inside?

quickcurrent

quickcurrent

#24

let's deal with things one at a time.

you couldn't be more correct in saying noises/problems can be deceiving.

i ripped apart the front brakes on my brother's 1 gen Dime (it's a Summer toy/show truck, doesn't see major use or abuse) 4 times trying to figure out why the right front tire would lock up below 40K (25MPH), and only if the truck (brakes) was warmed up (5-10 mins). replaced just about everything you can up there with no luck. end of the season, i pull apart his diff for service, and to install the winter storage tires and i find the left rear drum only willing to rotate backwards, and "hops" going forwards. pull off the drum, and find one of the shoe retaining springs had broke free and was jammed into the shoe, causing it to "grab" the inside of the drum when it heated up (big gouge in shoe and drum surface). explain to me how the oposite corner was affecting the performance of the front right baking?

i've used a large open end wrench (one that just fits over the axle diameter), and slowly "tapped" the wrench with a big piece of copper, alternating between sides to evenly set the bearing.

funny that you found a Chrysler pic for your reference (i actually like that, big MOPAR fan). as for putting your truck in neutral, yes it will. then rotate the carrier (ring gear assembly) so you can get access to them. usually whenever i've pulled a diff apart, once the pinion shaft has been pulled, you push in the axles, and the C-clips literally fall out themselves. yes you should replace the axle seals. one, because you have it apart already. two, they're cheap enough, so just do it.

good luck, and keep us posted on your success .

I'm only certain of death and taxes, lol. But thanks for your response. Glad you also think it's some bearings. Initially the noises seemed to be of more than one type so I think the u-joint was part of the problem, especially since it was loose.

The sounds seem to be coming from the rear end, to me, to my family members when they hear them, and to the auto tech that replaced the u-joint. So yes, I think it's the problem is in the back end, but sometimes these noises can be deceiving. I have to go with what appears to be the problem and try to nip it in the bud one step at a time. Heck, even the auto tech guys (two were looking at it) weren't positive what the problem component(s) were - one down and more to go, I guess.

The sounds seem to be coming from the rear end, to me, to my family members when they hear them, and to the auto tech that replaced the u-joint. So yes, I think it's the problem is in the back end, but sometimes these noises can be deceiving. I have to go with what appears to be the problem and try to nip it in the bud one step at a time. Heck, even the auto tech guys (two were looking at it) weren't positive what the problem component(s) were - one down and more to go, I guess.

i ripped apart the front brakes on my brother's 1 gen Dime (it's a Summer toy/show truck, doesn't see major use or abuse) 4 times trying to figure out why the right front tire would lock up below 40K (25MPH), and only if the truck (brakes) was warmed up (5-10 mins). replaced just about everything you can up there with no luck. end of the season, i pull apart his diff for service, and to install the winter storage tires and i find the left rear drum only willing to rotate backwards, and "hops" going forwards. pull off the drum, and find one of the shoe retaining springs had broke free and was jammed into the shoe, causing it to "grab" the inside of the drum when it heated up (big gouge in shoe and drum surface). explain to me how the oposite corner was affecting the performance of the front right baking?

What I see when looking at the differential is something like this https://w05.dealerconnect.chrysler.c...S/80011558.gif but the c-clip is illusive. Is it inside the space that the pinion shaft was in? Would placing the vehicle in neutral allow that mechanism to rotate to let me see inside?

quickcurrent

quickcurrent

good luck, and keep us posted on your success .

#25

nice pic's by the way TBB. those gears were a little.....uh......."rough".

regarding the fill plug quickcurrent, i'd remove it before reinstalling anyting. those plugs can be a real bitch sometimes. you may even need to "warm up" the area around the plug to free it. besides, tackling this before reassembly gives you more room to clean out the pumpkin of any dirt/debris that might get in there with removing it.

i'm not trying to scare you off of your task here, just giving you the heads up on any issues that may pop up on you.

falls under the "been there, done that" catagory.

regarding the fill plug quickcurrent, i'd remove it before reinstalling anyting. those plugs can be a real bitch sometimes. you may even need to "warm up" the area around the plug to free it. besides, tackling this before reassembly gives you more room to clean out the pumpkin of any dirt/debris that might get in there with removing it.

i'm not trying to scare you off of your task here, just giving you the heads up on any issues that may pop up on you.

falls under the "been there, done that" catagory.

#26

Thanks a lot old skool luvr, I need all the help I can get.

I've taken a couple of pictures of it which are too high a resolution to upload here, but I've posted them at web picassa, here

http://picasaweb.google.com/fjlopes/9242009#

so you can have a look at what I'm up against.

Sorry the trouble light didn't shed all that much light on the differential parts so they're a little dark, but you can see the locking screw loose and pulled out (it won't come right out for lack of clearance) and the space to the left of it where the pinion shaft was. I shine the light in all the crevices, I can see gears moving as I move the axle shaft hub, but can't see any c-clip!

quickcurrent

I've taken a couple of pictures of it which are too high a resolution to upload here, but I've posted them at web picassa, here

http://picasaweb.google.com/fjlopes/9242009#

so you can have a look at what I'm up against.

Sorry the trouble light didn't shed all that much light on the differential parts so they're a little dark, but you can see the locking screw loose and pulled out (it won't come right out for lack of clearance) and the space to the left of it where the pinion shaft was. I shine the light in all the crevices, I can see gears moving as I move the axle shaft hub, but can't see any c-clip!

quickcurrent

#27

Yeah you need to rotate the axles until the open 'window' of the carrier is in front of you and you should see them. Unless someone put a c-clip eliminator kit in but I don't know the first thing about them.

I would HIGHLY recommend putting the pinion shaft back in, rotating the axles/carrier until the square is facing you but still leaving enough room to get the pinion shaft back out. If you try and move things without that shaft in there, there's a good chance your spider gears will fall out and that's NO fun to put back together.

I would HIGHLY recommend putting the pinion shaft back in, rotating the axles/carrier until the square is facing you but still leaving enough room to get the pinion shaft back out. If you try and move things without that shaft in there, there's a good chance your spider gears will fall out and that's NO fun to put back together.

Last edited by TripleBlackBlazer; 09-25-2009 at 01:42 PM. Reason: change=/=chance

#28

Thanks bud, I'll try that later today.

I purchased the vehicle new from the dealer so it's the way GM built it, I believe the c-clip eliminator is an after market kit, so no chance of that being there.

The gears only rotate enough to hide the space occupied by the pinion shaft without the shaft in place. So it does make sense to do what you say, although I think I tried that already and couldn't get the shiny drum-like metal that the shaft goes into to turn to expose the c-clips, but I'll work on that some more.

The way it looks now, it's impossible to see any c-clips, so I've got to do something to get them out and get on with the job. I'm glad I've got other vehicles to drive in the meantime, but cold days will set in soon in the Toronto area and then it'll be less fun working on this, lol. The smell from this job in the garage is very overpowering too !!!

quickcurrent

I purchased the vehicle new from the dealer so it's the way GM built it, I believe the c-clip eliminator is an after market kit, so no chance of that being there.

The gears only rotate enough to hide the space occupied by the pinion shaft without the shaft in place. So it does make sense to do what you say, although I think I tried that already and couldn't get the shiny drum-like metal that the shaft goes into to turn to expose the c-clips, but I'll work on that some more.

The way it looks now, it's impossible to see any c-clips, so I've got to do something to get them out and get on with the job. I'm glad I've got other vehicles to drive in the meantime, but cold days will set in soon in the Toronto area and then it'll be less fun working on this, lol. The smell from this job in the garage is very overpowering too !!!

quickcurrent

#29

Yes the C-clips are the bronze colored items in tripple black's pic. He gave good advice not to rotate the carrier with the shaft removed. The small gears sometimes have spacers under them and they can be put back in if they fall out but it is no fun.

Have it in neutral. You need to position the lock bolt toward the bottom which will expose the opening where you can look in to see the C-clips. You will have to find the right spot so the lock bolt will come out and clear the bearing cap.Then push the axels in one at a time. Sometimes you have to hit them with a hammer if they won't just push in. Then the c-clip should fall out or you an reach in and get it out with your finger, magnet, needle nose pliers or what ever you need to get it out. Then the axle will pull out. Be careful not to let the axle splines cut the seal if you are not going to replace the seal. I suggest you replace both seals anyway. When you put the axle back in do not let the splines cut the seal and try to keep the axle from dragging on the seal as you put the axle back in.

I highly suggest that before you try to remove the lock bolt that you gently tap on each end to be sure it moves slightly. I have had them where the shaft wore into the lock bolt just enough that the lock bolt was jammed and it broke off when I tried to loosen it. If the lock bolt will not come out there is no way to dissasemble any further or remove the carrier as you can't get the axles out>>GRRRRR. Use a new lock washer on the lock bolt.

Rotate the carrier just far enough so the shaft will come out and clear the housing at the bottlm. Then if you need to rotate the carrier more to access the opening where the C-cilps are you can stick a finger in each hole where the shaft came out of the carrier then slowly and carefully rotate the carrier to expose the opening some more. Use your fingers to keep the small gears from rotating out of place. Be very alert so that anytime during the process that if there are spacers under the smalll gears that they do not fall out and if they do you will have to slip them back intio place.

Have it in neutral. You need to position the lock bolt toward the bottom which will expose the opening where you can look in to see the C-clips. You will have to find the right spot so the lock bolt will come out and clear the bearing cap.Then push the axels in one at a time. Sometimes you have to hit them with a hammer if they won't just push in. Then the c-clip should fall out or you an reach in and get it out with your finger, magnet, needle nose pliers or what ever you need to get it out. Then the axle will pull out. Be careful not to let the axle splines cut the seal if you are not going to replace the seal. I suggest you replace both seals anyway. When you put the axle back in do not let the splines cut the seal and try to keep the axle from dragging on the seal as you put the axle back in.

I highly suggest that before you try to remove the lock bolt that you gently tap on each end to be sure it moves slightly. I have had them where the shaft wore into the lock bolt just enough that the lock bolt was jammed and it broke off when I tried to loosen it. If the lock bolt will not come out there is no way to dissasemble any further or remove the carrier as you can't get the axles out>>GRRRRR. Use a new lock washer on the lock bolt.

Rotate the carrier just far enough so the shaft will come out and clear the housing at the bottlm. Then if you need to rotate the carrier more to access the opening where the C-cilps are you can stick a finger in each hole where the shaft came out of the carrier then slowly and carefully rotate the carrier to expose the opening some more. Use your fingers to keep the small gears from rotating out of place. Be very alert so that anytime during the process that if there are spacers under the smalll gears that they do not fall out and if they do you will have to slip them back intio place.

Last edited by terry s; 09-25-2009 at 08:50 AM.