High fuel trims, and drivability problems

#42

Definitely in it for the haul to get this thing fixed. I start a new job tomorrow, so I won't have allot of free time to test, but whenever I'm not working, I'll come back here with findings. The P0135 popped up 3-4 days ago, and I put a new sensor in thinking that maybe the bad O2 was causing my problems. The code just resurfaced today on the drive where I did the WOT test.

#43

I've been setting my scanner up to record data everytime I start the truck and take off. That way when it acts up again, I'll have the data.

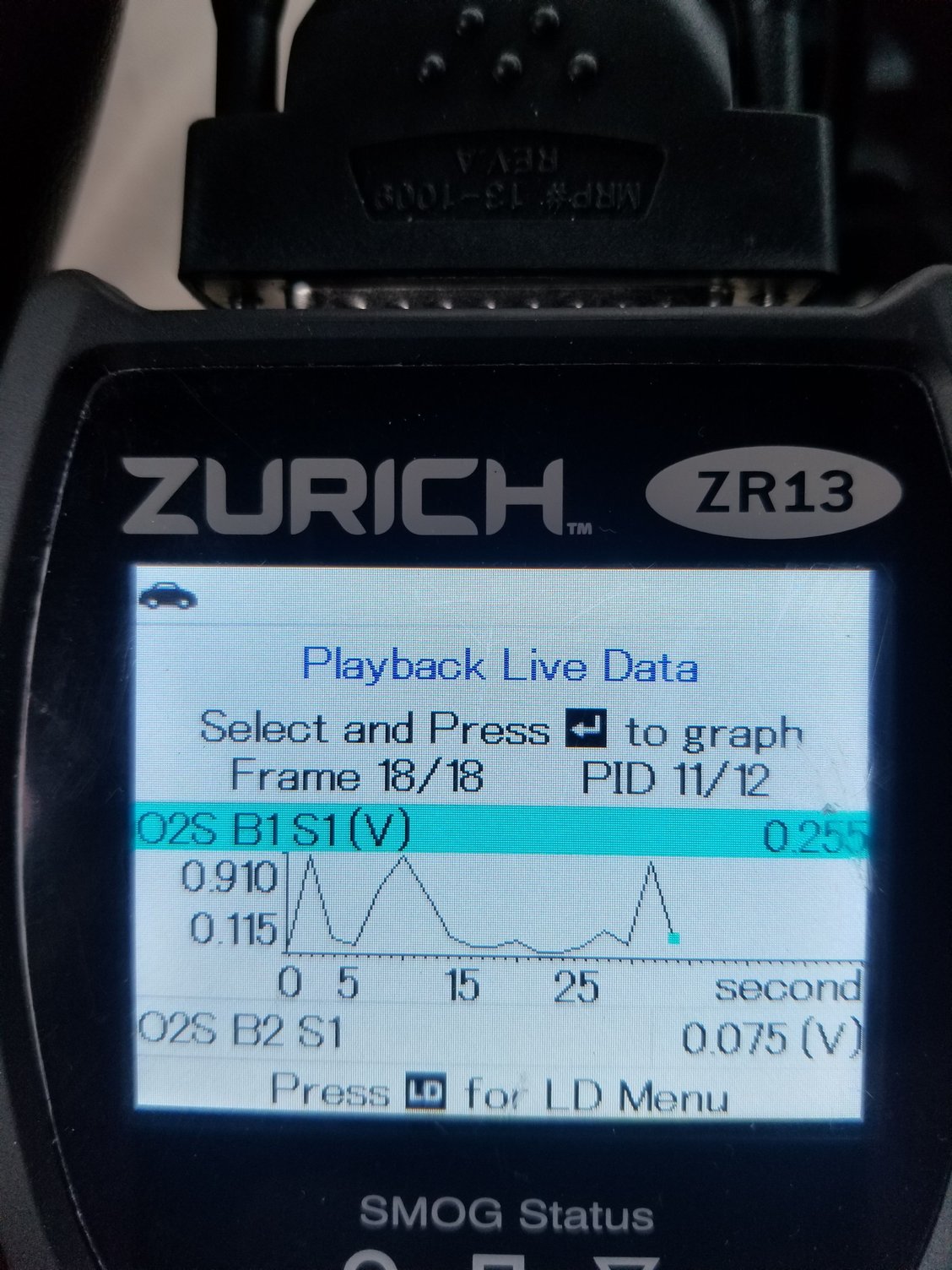

One thing I noticed tonight was that my O2 on bank 1 was reading mid-upper 4v range while backing down my driveway, while the O2 on bank 2 was in the mid 1v range.

Not sure if that is anything significant. My brain is mush from all the numbers and testing the past week, but it'll be worth it in the end.

One thing I noticed tonight was that my O2 on bank 1 was reading mid-upper 4v range while backing down my driveway, while the O2 on bank 2 was in the mid 1v range.

Not sure if that is anything significant. My brain is mush from all the numbers and testing the past week, but it'll be worth it in the end.

#44

P0135 is a faulty heating element circuit for the O2 sensor. Of course its possible that a new O2 sensor has a faulty heating element but not likely. Your going to need to check voltage and ground to that sensor. Wiring problems could be at the root of your issues. While not likely so can the engine computer.

George

George

#46

A few more thoughts on your P0135 code. This is supposed to indicate a faulty O2 sensor heater circuit, either the heater element or the wiring/pcm. Sometimes its described as detection of out of bounds heater current but I have also seen it described as when it takes too long for the sensor to heat up and start switching as in my previous graph. I dont know which method is used here but if its delayed switching then the sensor may not be defective and its because the lean condition has the sensor pegged low and the rich command indicated in the fuel trims is not working (fuel delivery restrictions, injectors, major air leak, etc. You still need to check the power and ground to the sensor and do all the previous tests described to nail this gremlin to the wall for good. The trick as you point out is to catch this while its misbehaving. Since you now have codes, freeze frame data may give you more clues.

George

George

#48

Looks like one data point about every 2 seconds to me on photo immediately above. Graphing using your meter is not working for you. Not nearly fast enough to catch pertinent data and/or look at cycling of O2 sensors and Fuel Trims. Sorry but you need better equipment. Have you considered Torque Pro or Dash Command or Car Gauge Pro (now Car Diagnostic Pro) with the BAFX Bluetooth OBD2 adapter? I get 25-30 data points per second with mine. Only costs about $35

Why not just list your readings in a simple table instead of taking a photo of everything? A one-stop shop. Makes the thread too busy IMHO

p.s. George will get you there if you stick with him!

Why not just list your readings in a simple table instead of taking a photo of everything? A one-stop shop. Makes the thread too busy IMHO

p.s. George will get you there if you stick with him!

Last edited by LesMyer; 12-22-2020 at 09:00 AM.

#49

I know that you said you started a new job so your testing time is limited so we donít have everything we need yet. That said I need to figure out what we know and what we donít know. First however and to Lesí points:

Some data is better as data points/summaries and some data is better as a graph as itís the only way to see whatís going on like O2 switching.

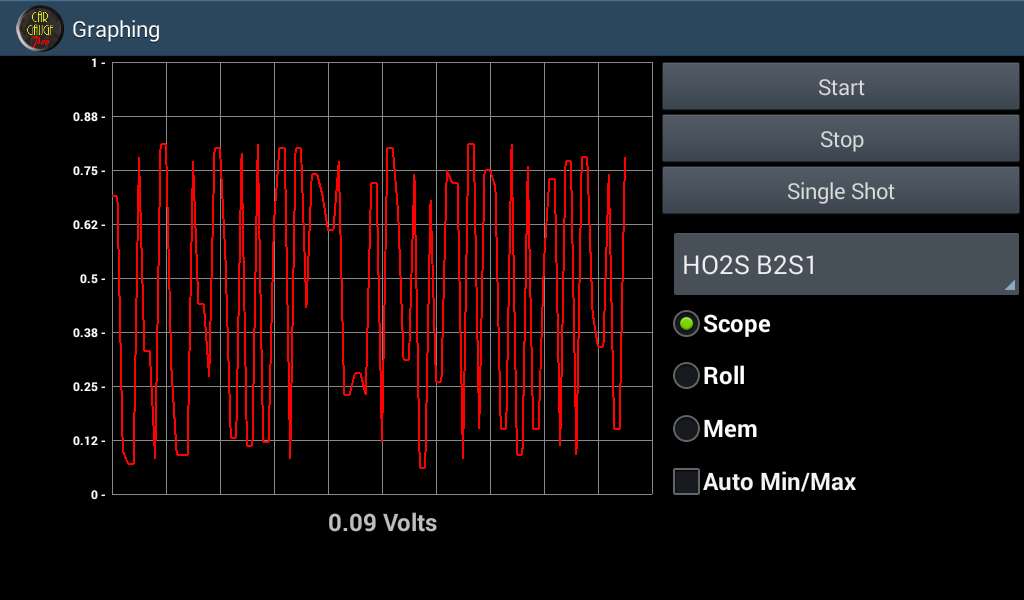

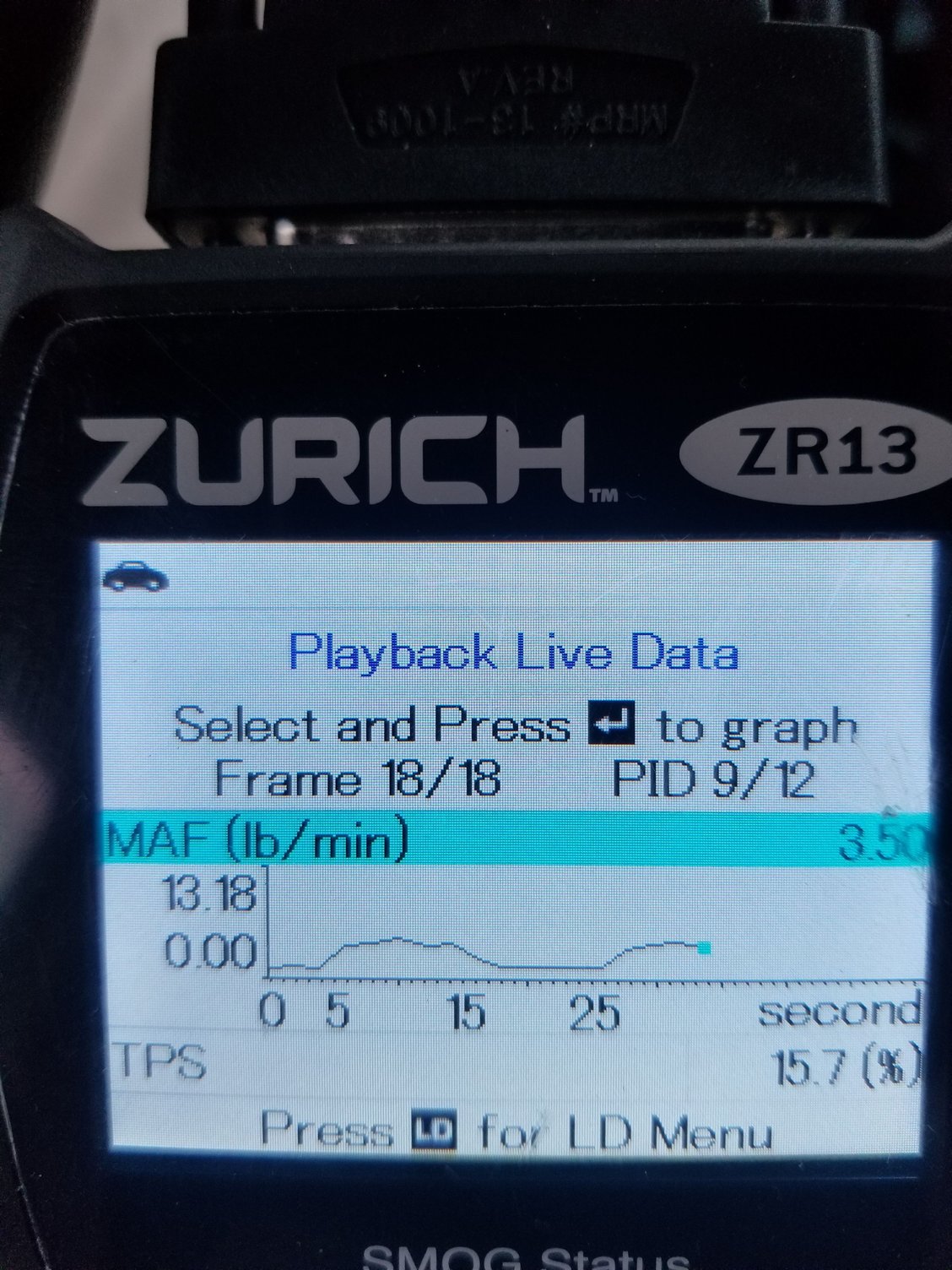

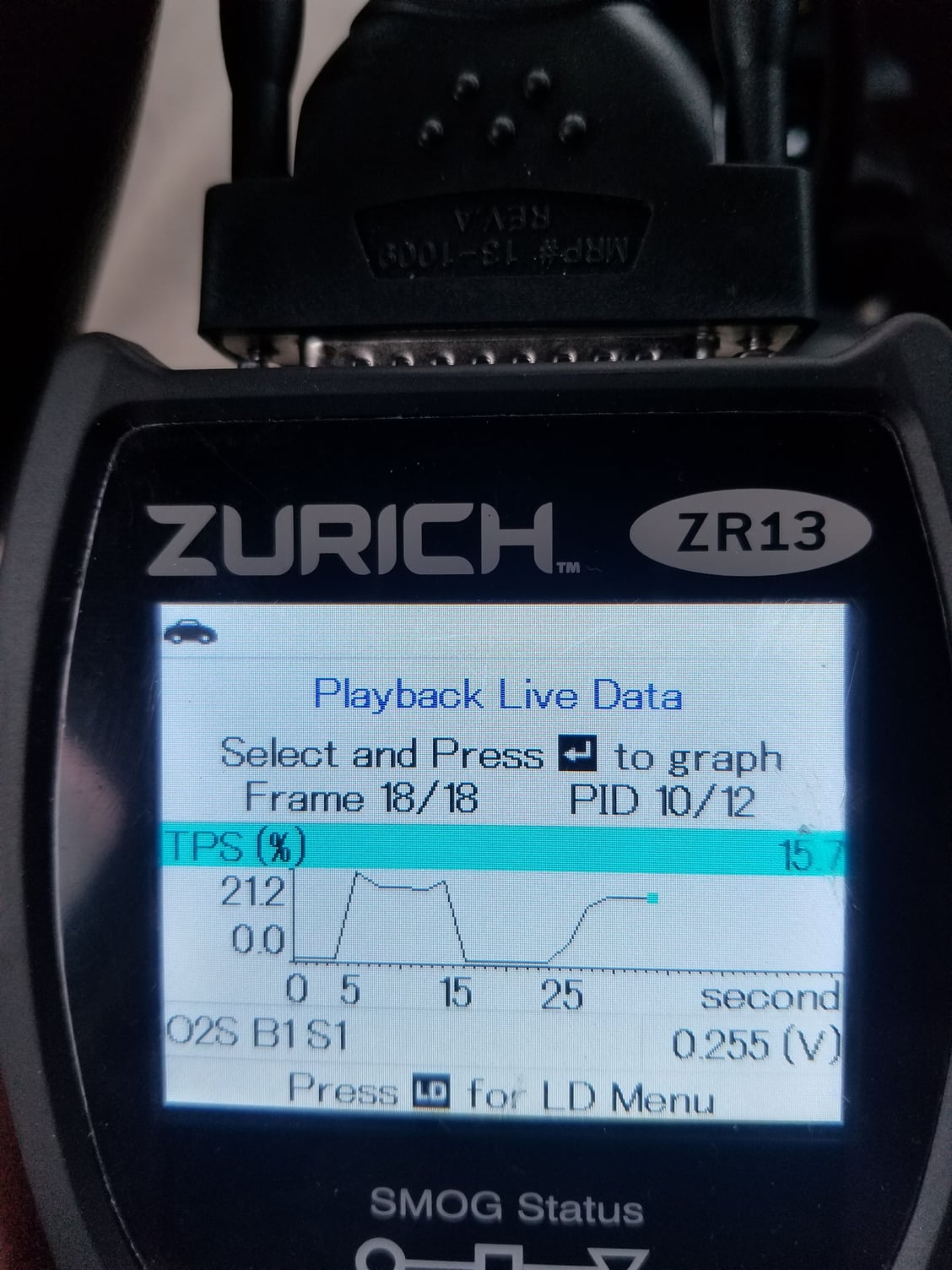

Healthy O2 sensors switch at between 1-5 hz or times per second into the rails (0.2 to 0.8 ish) most of the time. I canít tell in your graphs if we are capturing enough data points to see the O2 sensors functioning properly. Can you change the time base or data point rate? Have you ever seen them switching like in the graphs I have sent you? Scanners have limited cpu capacity so limiting to the pids needed will allow some scanners to capture better/more data.

Can you change the units on the MAF to grams/second?

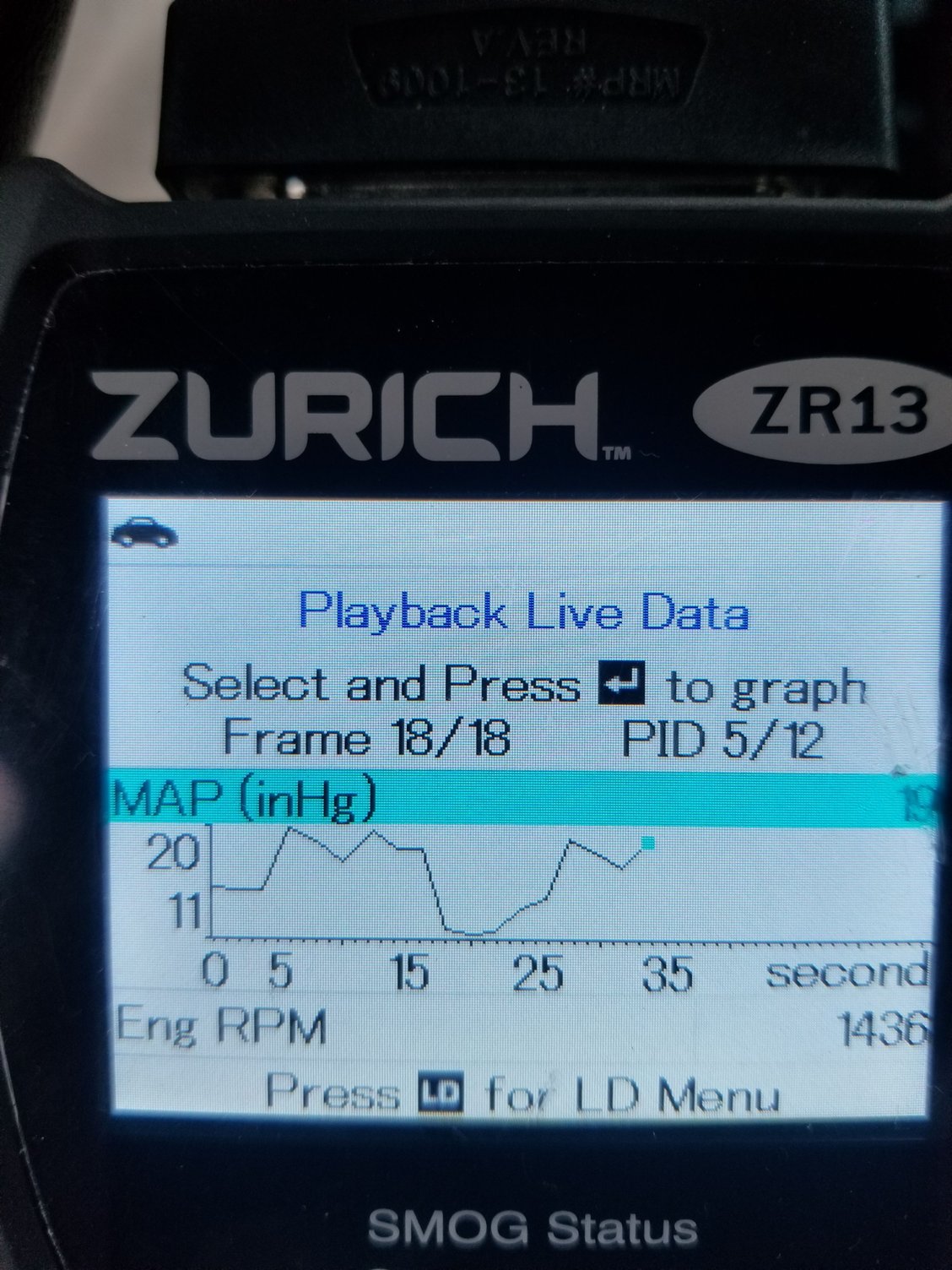

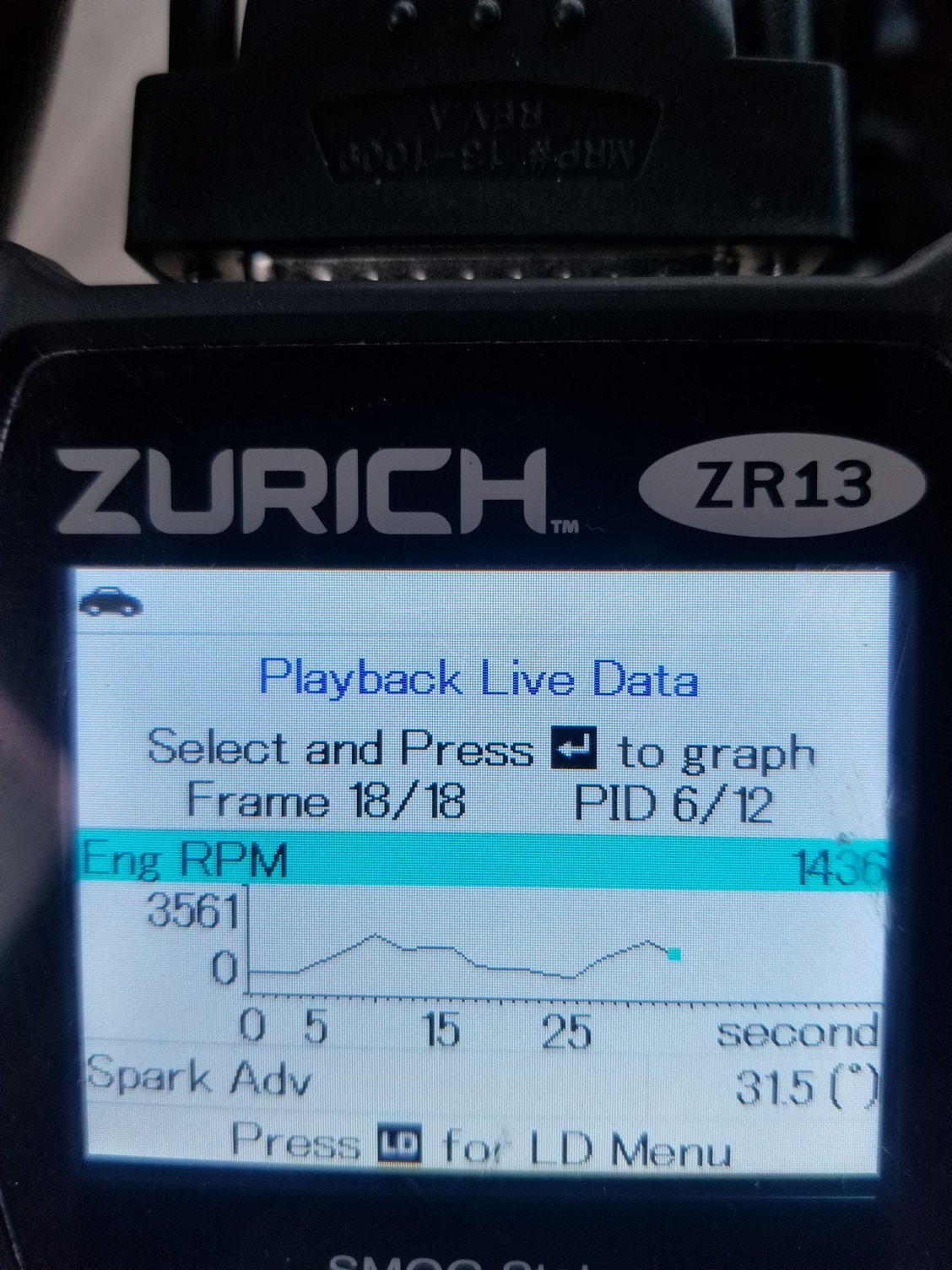

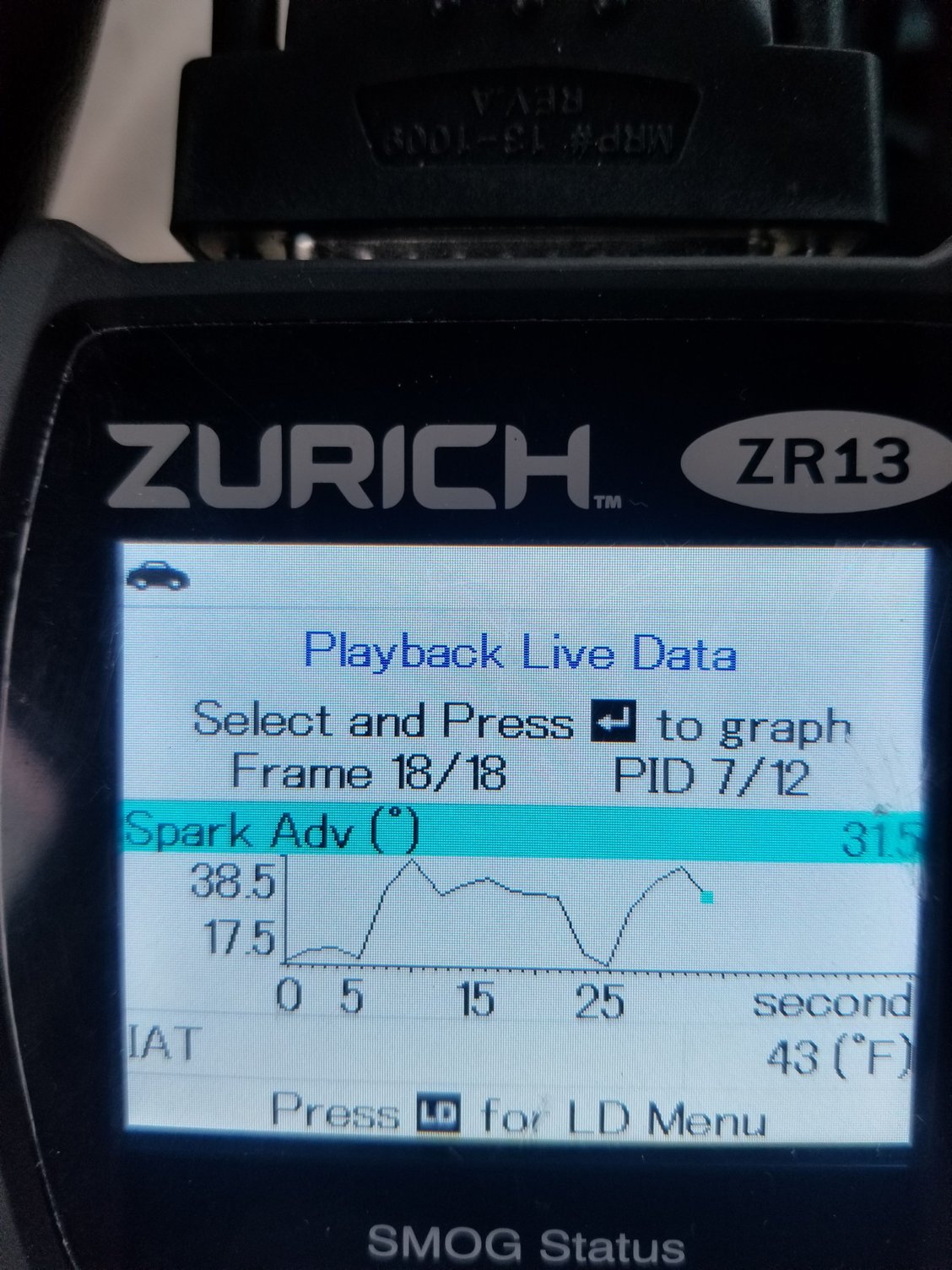

Have you captured the tabular data for the sensor list I gave you on a cold and warm engine to rule out sensor malfunction in the first order? ECT, MAP, TPS, IAT.

Your scanner can only display two graphs at a time or can only capture two graphs at a time? Iím trying to figure out if we have captured the WOT test with all of the necessary graphs when the engine is running bad.

Do you have freeze frame capability for the codes that you have?

You seem interested to learn and remote control analysis at this level can be difficult but Iíll stay with you as long as it takes. You have already shown some commitment to a higher level of diagnostics with a graphing scanner but to Lesí point, some additional capability may be in order. He can get you some awesome capability for well under $100, even around $35 as he said, he knows most of the cost effective options. I have a number of scan tools including a high end Snap On which great but for what we are doing here I have just as much fun and can get all the data needed with these lower cost options. Years ago I bought a used android tablet on eBay with an Amazon BT dongle and the software that Les outlined, good stuff. I actually like the graphs and data capture gauges better. As long as you donít need to bleed abs systems or command modules, do relearn, etc then you donít need to spend high dollars. There is also a roughly $100 option floating around here that is supposed to be pretty good, I remember Les and one other member evaluating it.

Data is power. Information is even better.

George

Some data is better as data points/summaries and some data is better as a graph as itís the only way to see whatís going on like O2 switching.

Healthy O2 sensors switch at between 1-5 hz or times per second into the rails (0.2 to 0.8 ish) most of the time. I canít tell in your graphs if we are capturing enough data points to see the O2 sensors functioning properly. Can you change the time base or data point rate? Have you ever seen them switching like in the graphs I have sent you? Scanners have limited cpu capacity so limiting to the pids needed will allow some scanners to capture better/more data.

Can you change the units on the MAF to grams/second?

Have you captured the tabular data for the sensor list I gave you on a cold and warm engine to rule out sensor malfunction in the first order? ECT, MAP, TPS, IAT.

Your scanner can only display two graphs at a time or can only capture two graphs at a time? Iím trying to figure out if we have captured the WOT test with all of the necessary graphs when the engine is running bad.

Do you have freeze frame capability for the codes that you have?

You seem interested to learn and remote control analysis at this level can be difficult but Iíll stay with you as long as it takes. You have already shown some commitment to a higher level of diagnostics with a graphing scanner but to Lesí point, some additional capability may be in order. He can get you some awesome capability for well under $100, even around $35 as he said, he knows most of the cost effective options. I have a number of scan tools including a high end Snap On which great but for what we are doing here I have just as much fun and can get all the data needed with these lower cost options. Years ago I bought a used android tablet on eBay with an Amazon BT dongle and the software that Les outlined, good stuff. I actually like the graphs and data capture gauges better. As long as you donít need to bleed abs systems or command modules, do relearn, etc then you donít need to spend high dollars. There is also a roughly $100 option floating around here that is supposed to be pretty good, I remember Les and one other member evaluating it.

Data is power. Information is even better.

George

#50

I'll definitely look into getting one of those. Thanks.