Hard start - Did fuel leakdown tests - advice?

#21

Yea, wow defiantly clean those out with a brush and some carb cleaner. Put some silicon plumbers grease on the injector O rings. Then in a week pull the plenum one more time and see if there still snug, if not you have blow back combining from someplace pushing them out.

#22

You're on your way to proving your "mechanic" is not as good as he claims to be

Clean the ports out best as possible. Best not to spray directly into the port or it may flood the engine. Carb cleaner on a rag, or Q tip, would work. The new injectors must "snap" in place, and not pull out.

Couple of places in the lower intake showing signs of fuel leaks. The "golden" color is the clue. You're doin' fine, keep up the good work!

Clean the ports out best as possible. Best not to spray directly into the port or it may flood the engine. Carb cleaner on a rag, or Q tip, would work. The new injectors must "snap" in place, and not pull out.

Couple of places in the lower intake showing signs of fuel leaks. The "golden" color is the clue. You're doin' fine, keep up the good work!

#23

Thanks! It's pretty fun working on my blazer at least until I get stuck. Anywho....

So clean with carb cleaner, gotcha. So I should not try to buy a small brush to scrub on the inside and just use q-tips to get as far down as I can? Do I need to worry about cleaning the whole plenum up or just forget it?

If I have to take it off again in a couple weeks to make sure there isn't any blow back, I will....but if it's not necessary, i'll probably leave it until I have any problems.

The #1 injector was the one really wet, 6 was wet too. But 4 and 6 both were just chilling in there and required 0 effort to pull them out.

I hate to ask more questions but I am. Should I use thread sealant on the upper intake bolts? From the looks, there wasn't any on there before and do I need rtv silicone for the gasket or just use petroleum jelly or something that sorts? I've searched and googled these questions but get different answers. Thanks.

So clean with carb cleaner, gotcha. So I should not try to buy a small brush to scrub on the inside and just use q-tips to get as far down as I can? Do I need to worry about cleaning the whole plenum up or just forget it?

If I have to take it off again in a couple weeks to make sure there isn't any blow back, I will....but if it's not necessary, i'll probably leave it until I have any problems.

The #1 injector was the one really wet, 6 was wet too. But 4 and 6 both were just chilling in there and required 0 effort to pull them out.

I hate to ask more questions but I am. Should I use thread sealant on the upper intake bolts? From the looks, there wasn't any on there before and do I need rtv silicone for the gasket or just use petroleum jelly or something that sorts? I've searched and googled these questions but get different answers. Thanks.

#24

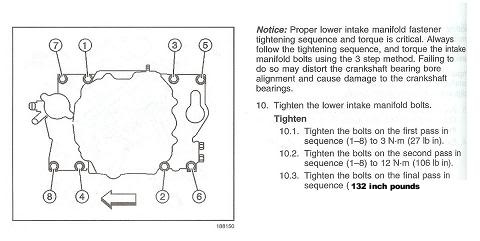

From what you're saying, who ever did the job before, didn't pay much attention to detail... all rookie mistakes. I can imagine that the intake was not torqued properly too. It is mandatory to follow the tightening sequence and torque specs.

#25

Thanks for the response captain. Just trying to do this job right! When you are using the tap and die, you want to use the right size for the bolts that were already in there correct? It won't mess up the holes for the upper intake right? Sorry, never taped and died anything so just curious.

And about the rtv stuff, I was researching more today, so I don't need to use any rtv if I just use the rubber gasket right? But if I wanted to use rtv instead of the rubber gasket I could? I'm planning on using the rubber gasket that came with the new spider assembly. Sorry for more questions, just making sure I understand.

And about the rtv stuff, I was researching more today, so I don't need to use any rtv if I just use the rubber gasket right? But if I wanted to use rtv instead of the rubber gasket I could? I'm planning on using the rubber gasket that came with the new spider assembly. Sorry for more questions, just making sure I understand.

#26

Forgive me if I misread something Captain, but I don't think Davecubs has removed the lower intake. You'll only need the RTV for the front and back seal when re-seating the lower intake. For the upper plenum, throttle body, fuel injector spider etc... Just use the new premade rubber gaskets. Smear a little clean oil on the spider gasket prior to reseating the upper plenum too, helps it slide on a little easier. I didn't use any thread sealer on the upper plenum bolts as it did not look like there was any used previously. I did use sealer on the lower intake bolts after chasing the threads just like the boss said... So again, if I missed something, my apologies. If you're still just working with the upper plenum removed, then don't worry about the RTV stuff...

Keep up the good work!!!

Keep up the good work!!!

#27

Hey Doc, good catch! I'm the one that misread, sorry.

No RTV anywhere with the plenum, (upper intake). Use the new silicone rubber gaskets supplied in the gasket set. Disregard the business about chasing the threads in the heads & bolts, do what the good Doctor ordered and you'll be golden

No RTV anywhere with the plenum, (upper intake). Use the new silicone rubber gaskets supplied in the gasket set. Disregard the business about chasing the threads in the heads & bolts, do what the good Doctor ordered and you'll be golden

#28

Worked on it a little bit more today - Got the plenum back on, torqued down. I'm having a tough time putting the fuel lines back in the spider assembly. I keep pushing them down into the top of the assembly but they keep springing back out. Any advice on getting them to stay? Thanks!

#29

O rings, washers, and retainers, all have to go in like this. Helps if you put some clean motor oil on the lines before you slide them in the metering block.

#30

I like that diagram! So are those pieces not already in the assembly? Non of those came out when I pulled the lines from the other spider. So I figured I could just stick them right into the new one. If I need to buy any of those washers and o rings, where do I get them from? Thanks captain!